Chiral auxetic metamaterial structure with compression-shear coupling characteristic and preparation method thereof

A technology of material structure and chirality, applied in mechanical equipment, processing and manufacturing, additive processing, etc., can solve the problems that are difficult to meet the needs of practical applications, cumbersome process flow, and few applicable materials, so as to achieve integrated manufacturing, Simplify the preparation process and increase the effect of manufacturing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing a chiral auxetic metamaterial structure with compression-shear coupling characteristics of the present invention comprises the following steps:

[0051] S1. Select a polygonal ring structure as the unit cell shape, and connect the corresponding number of connecting rods with the polygonal ring structure at the vertices of the polygonal ring structure at an acute angle, and then arrange the two-dimensional unit cell structure in an array on the plane and mutually Connect to obtain a planar model, and due to preparation requirements, stretch the planar model in the vertical direction to obtain a prepared model;

[0052] S2. Using Solidworks software to carry out geometric modeling and configuration design of the model;

[0053] First establish a two-dimensional unit cell structure, including the side length and width of the polygonal ring structure, the length and width of the connecting rod, the connection angle between the connecting rod and the p...

Embodiment 1

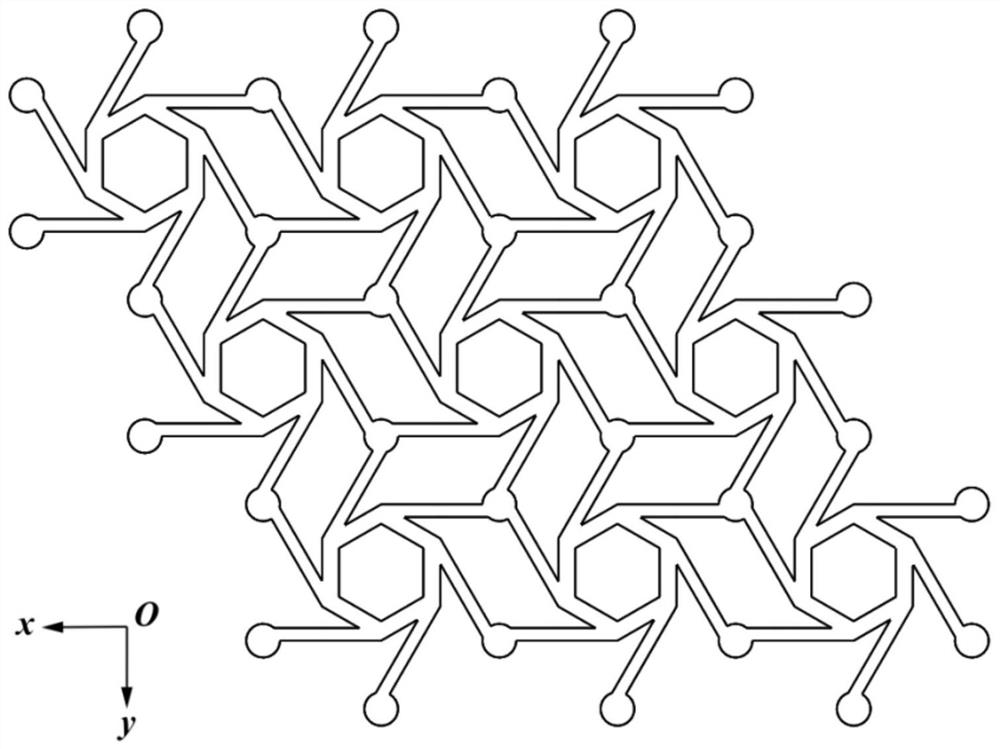

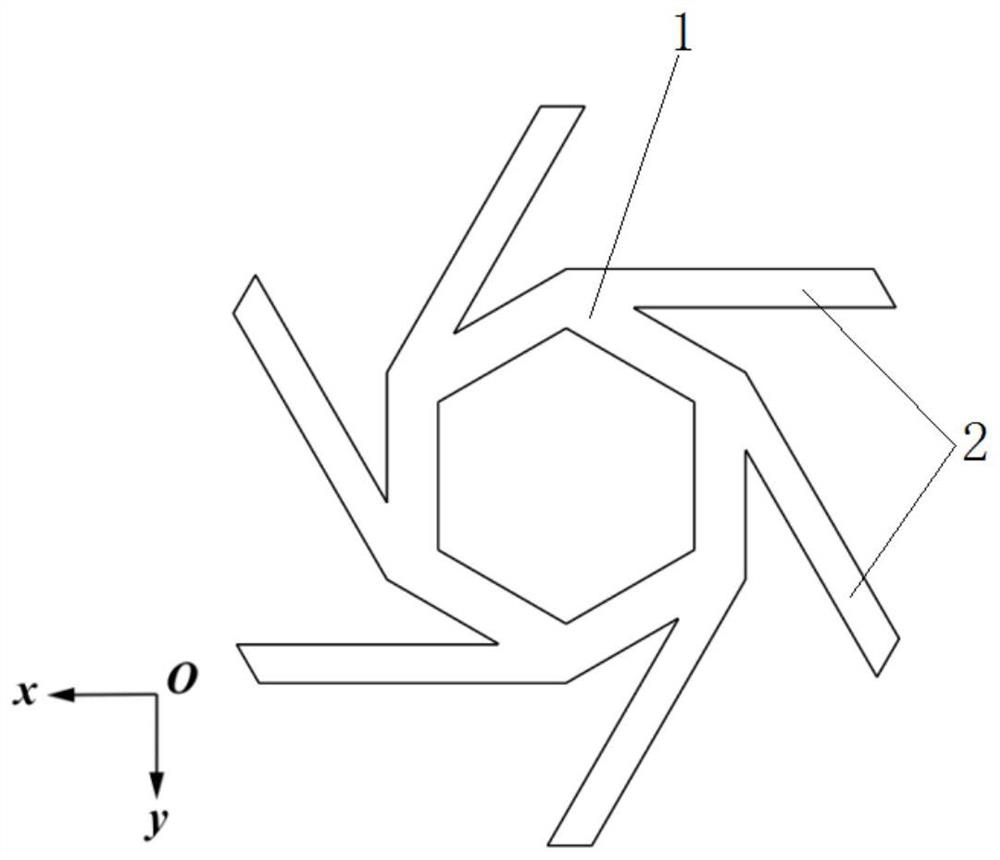

[0057] see figure 1 and figure 2 , a chiral auxetic metamaterial with compression-shear coupling properties, obtained from a two-dimensional unit cell structure through a planar array, the unit cell is composed of regular hexagonal rings with connecting rods, and the connecting rods and rings are in the The vertices are connected at an acute angle and are distributed in a circular array centered on the centroid of the ring; the unit cells are arranged in an array in the X direction and a direction 120° from X on the plane. On the XOY plane, the connecting rods of adjacent units intersect with connected in a circular fashion.

[0058] A method for preparing a chiral auxetic metamaterial with compression-shear coupling characteristics, the specific steps are as follows:

[0059] Step 1: Select a regular hexagonal ring as the shape of the unit cell, and connect the six connecting rods and the ring at the vertices of the regular hexagon at an acute angle, and then distribute th...

Embodiment 2

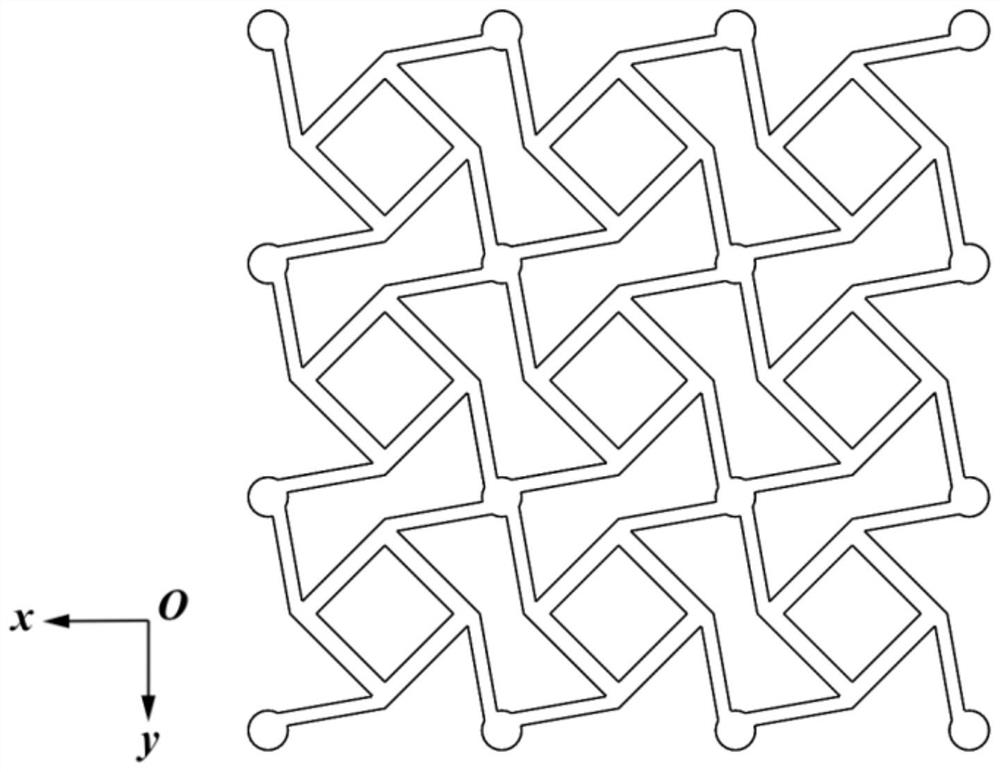

[0064] see figure 1 and figure 2 , a chiral auxetic metamaterial with compression-shear coupling characteristics, referring to Example 1, the difference is that the regular hexagonal ring can be replaced by a square ring, the number of connecting rods becomes 4, and the connecting rods and rings are in a square The vertices are connected at an acute angle and distributed in a circular array centered on the centroid of the ring. The unit cells are arranged in an array in the X direction and the Y direction on the plane. On the XOY plane, the connecting rod intersections of adjacent units are connected in a circular manner.

[0065] A method for preparing a chiral auxetic metamaterial with compression-shear coupling characteristics, the specific steps are as follows:

[0066] Referring to step 2 in Example 1, the difference is that the side length and width of the square ring are 10.36mm and 2mm respectively, the length and width of the connecting rod are 10.32mm and 1.5mm re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com