Movable minitype medium-low radioactive waste gasification and melting treatment system and method thereof

A gasification-melting, low-radioactive technology, applied in the field of low-radioactive waste gasification-melting processing systems, can solve the problems of unfavorable radionuclide capture and control, increased temporary storage pressure of radioactive waste, increased tail gas treatment burden and cost, etc. Achieve the effect of reducing processing costs and risks, facilitating flexible control and monitoring, and achieving good capacity reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

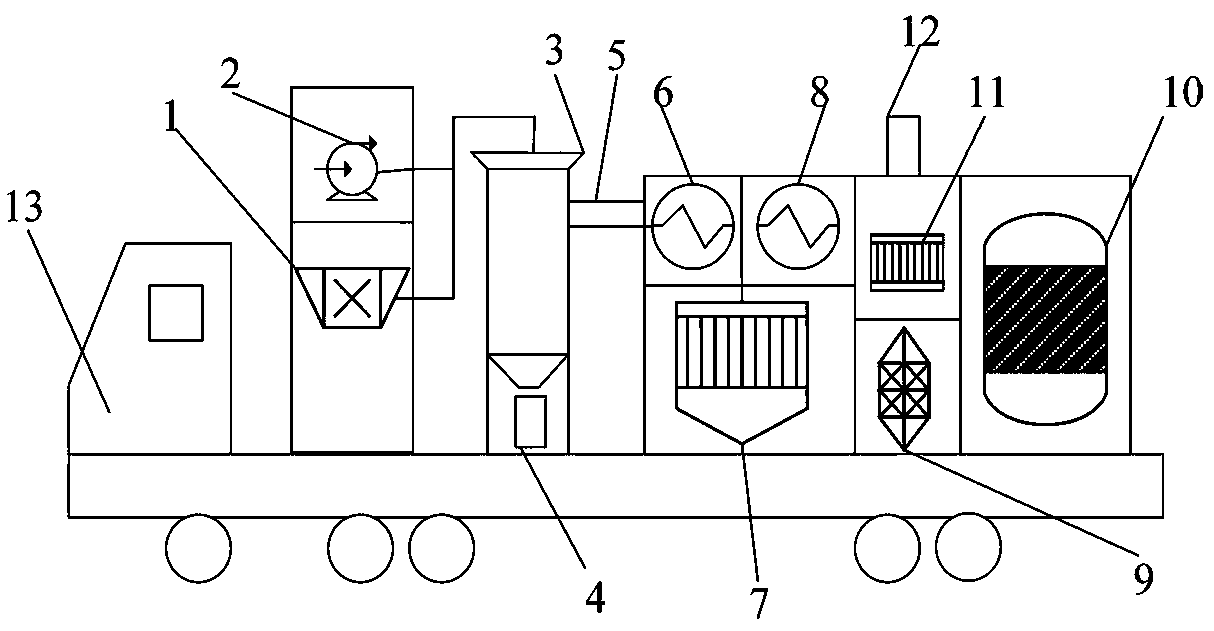

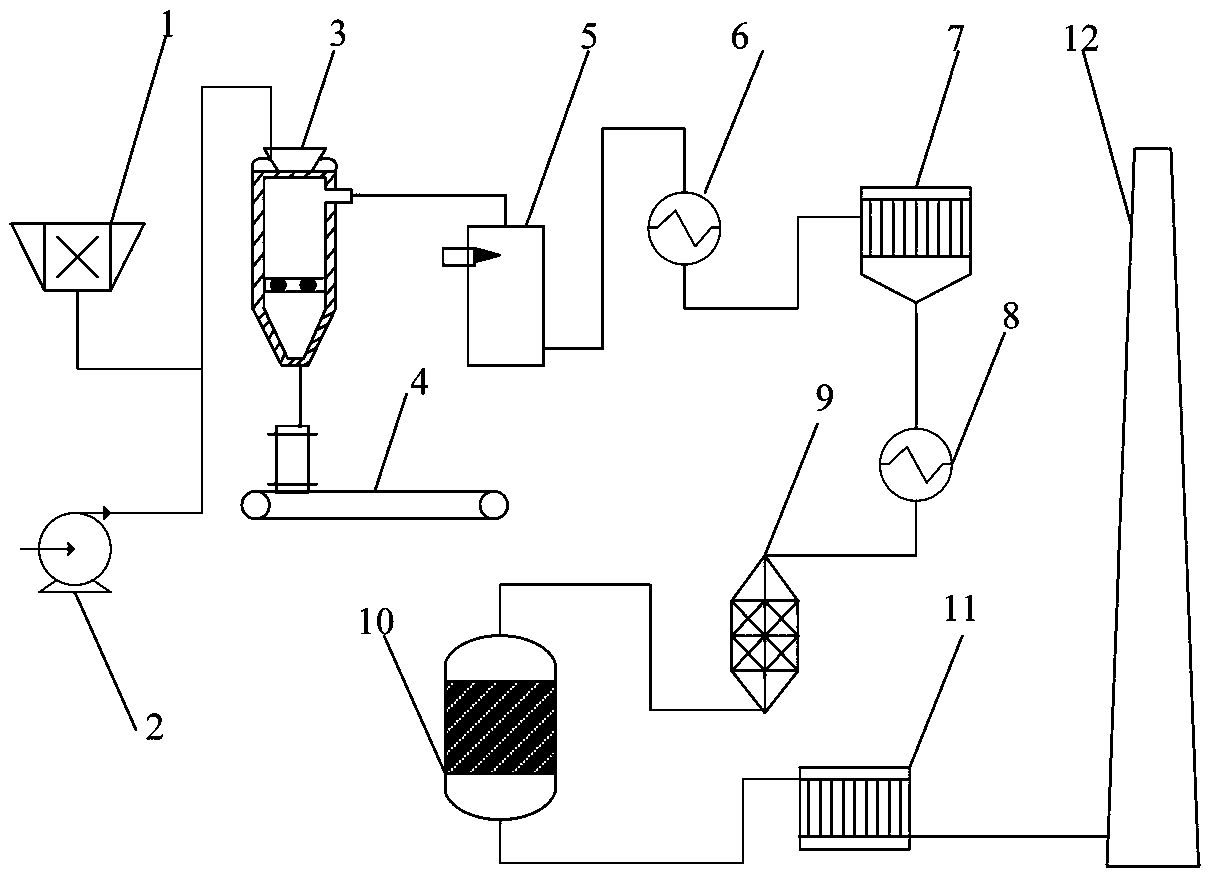

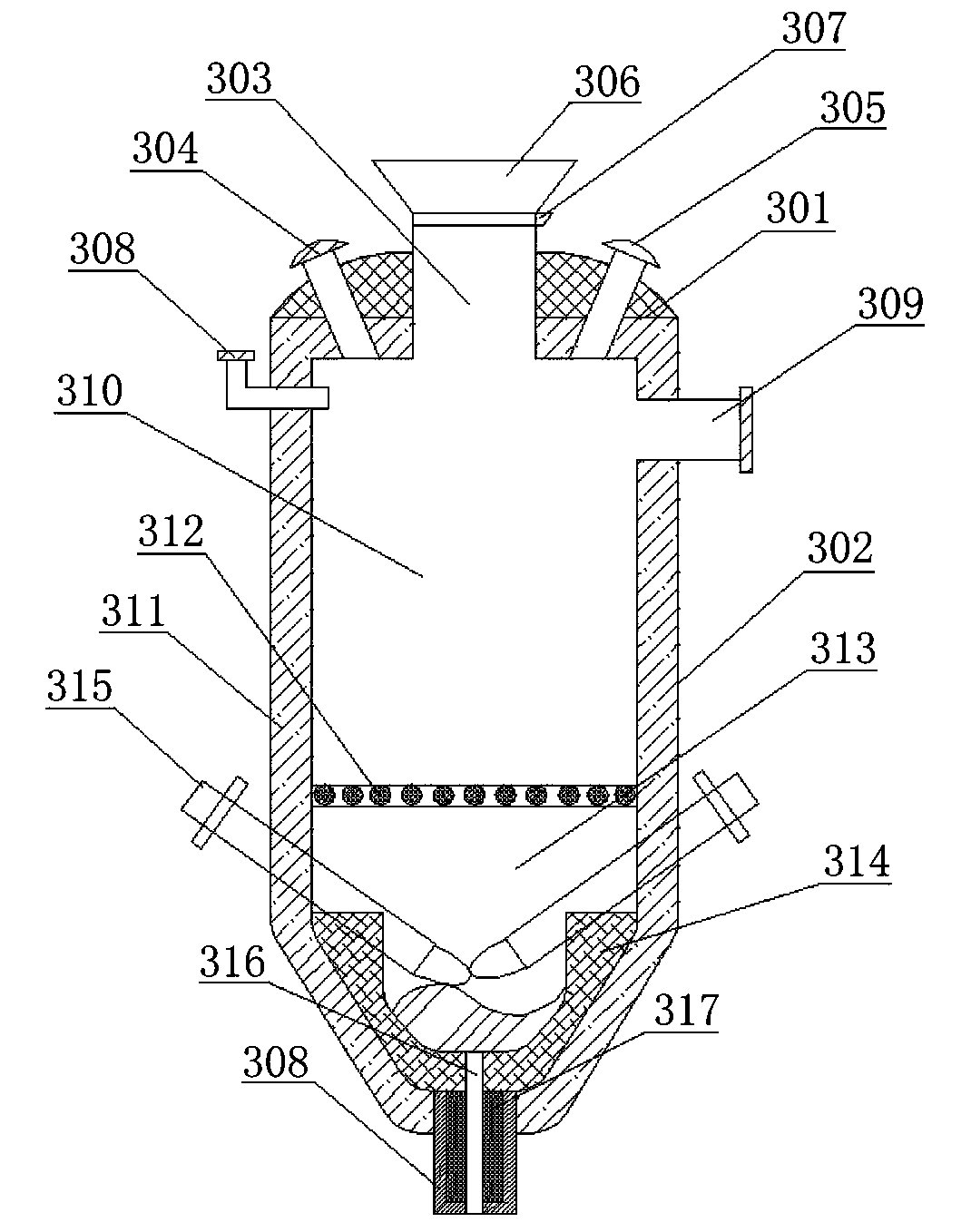

[0025] Such as figure 1 As shown in or 2, a mobile small-scale low-to-medium radioactive waste gasification and melting treatment system of the present invention includes a crusher 1, a pneumatic diaphragm pump 2, a plasma gasification and melting furnace 3, a molten glass body receiver 4, and a combustion chamber 5 , first-level direct heat exchanger 6, ceramic filter 7, second-level direct heat exchanger 8, activated carbon adsorption tower 9, deacidification washing tower 10, high-efficiency air filter 11, chimney 12 and mobile equipment 13, crusher 1 out The feed port is connected to the feed port of the plasma gasification melting furnace 3 through a shaftless screw feeder, the output end of the pneumatic diaphragm pump 2 is connected to the feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com