Purification process of octamethylcyclotetrasiloxane

An octamethylcyclotetrasiloxane and process technology, applied in the direction of silicon organic compounds, etc., can solve problems such as complex operation process, achieve the effects of high process integration, low metal impurity content, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 8

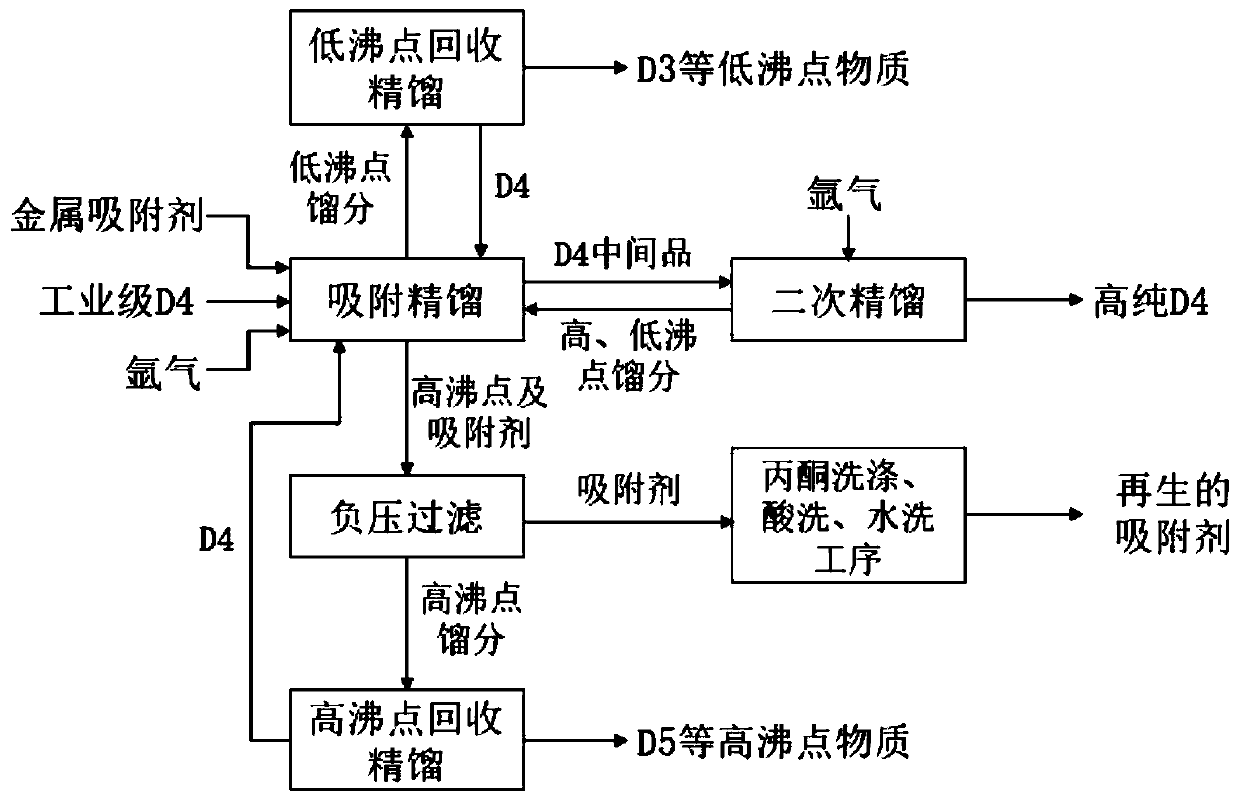

[0029] The purification process X1 of embodiment 1 octamethylcyclotetrasiloxane

[0030] Such as figure 1 As shown, the industrial octamethylcyclotetrasiloxane (D4) with a content of 90% and the adsorbent PEI / SiO 2 According to the ratio of 1:0.01 into the reactive distillation column. Introduce high-purity argon, start the pneumatic agitator, and heat the tower kettle to 168-178°C under negative pressure of -1 to -3k Pa. After maintaining the slight boiling state for 2 hours, increase the heating power, and react with total reflux for 3 hours, and control the reflux Ratio 4:1~12:1, cut off the fraction between 170~180°C to obtain the D4 intermediate product of primary rectification; combine the high boiling point residual liquid with PEI / SiO 2 released from the bottom of the tower.

[0031] The primary rectification D4 intermediate product obtained by the reactive distillation tower is introduced into the secondary rectification tower along with the pipeline, and the high-...

Embodiment 2 8

[0034] The purification process X2 of embodiment 2 octamethylcyclotetrasiloxane

[0035] Put D4 with a content of 90% and adsorbent 13X molecular sieve into the reactive distillation column according to the ratio of 1:0.005. Introduce high-purity argon, start the air flow agitator, and heat the tower kettle to 168-178°C under negative pressure of -2 to -3k Pa. After maintaining the slight boiling state for 1 hour, increase the heating power, and react with total reflux for 3 hours, and control the reflux The ratio is 4:1~12:1, and the fraction between 170~180°C is cut off to obtain the D4 intermediate product of primary rectification; the high boiling point residual liquid and 13X molecular sieve are released from the bottom of the tower.

[0036] The primary rectification D4 intermediate product obtained by the reactive distillation tower is introduced into the secondary rectification tower along with the pipeline, and the flow rate of the empty tower is 3.0×10 -3 m / s high-p...

Embodiment 3 8

[0039] The purification process X3 of embodiment 3 octamethylcyclotetrasiloxane

[0040] Put the industrial octamethylcyclotetrasiloxane (D4) with a content of 90% and the adsorbent disodium ethylenediamine tetraacetate into the reactive distillation column according to the ratio of 1:0.01. Introduce high-purity argon, start the pneumatic agitator, and heat the tower kettle to 168-178°C under negative pressure of -15~-20kPa. After maintaining the slight boiling state for 10 hours, increase the heating power, and perform full reflux reaction for 3 hours, and control the reflux The ratio is 4:1~12:1, and the fraction between 170~180°C is intercepted to obtain the D4 intermediate product of primary rectification; the high boiling point residual liquid and disodium ethylenediaminetetraacetic acid are released from the bottom of the tower.

[0041] The initial rectification D4 intermediate product obtained by the reactive distillation tower is introduced into the secondary rectific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com