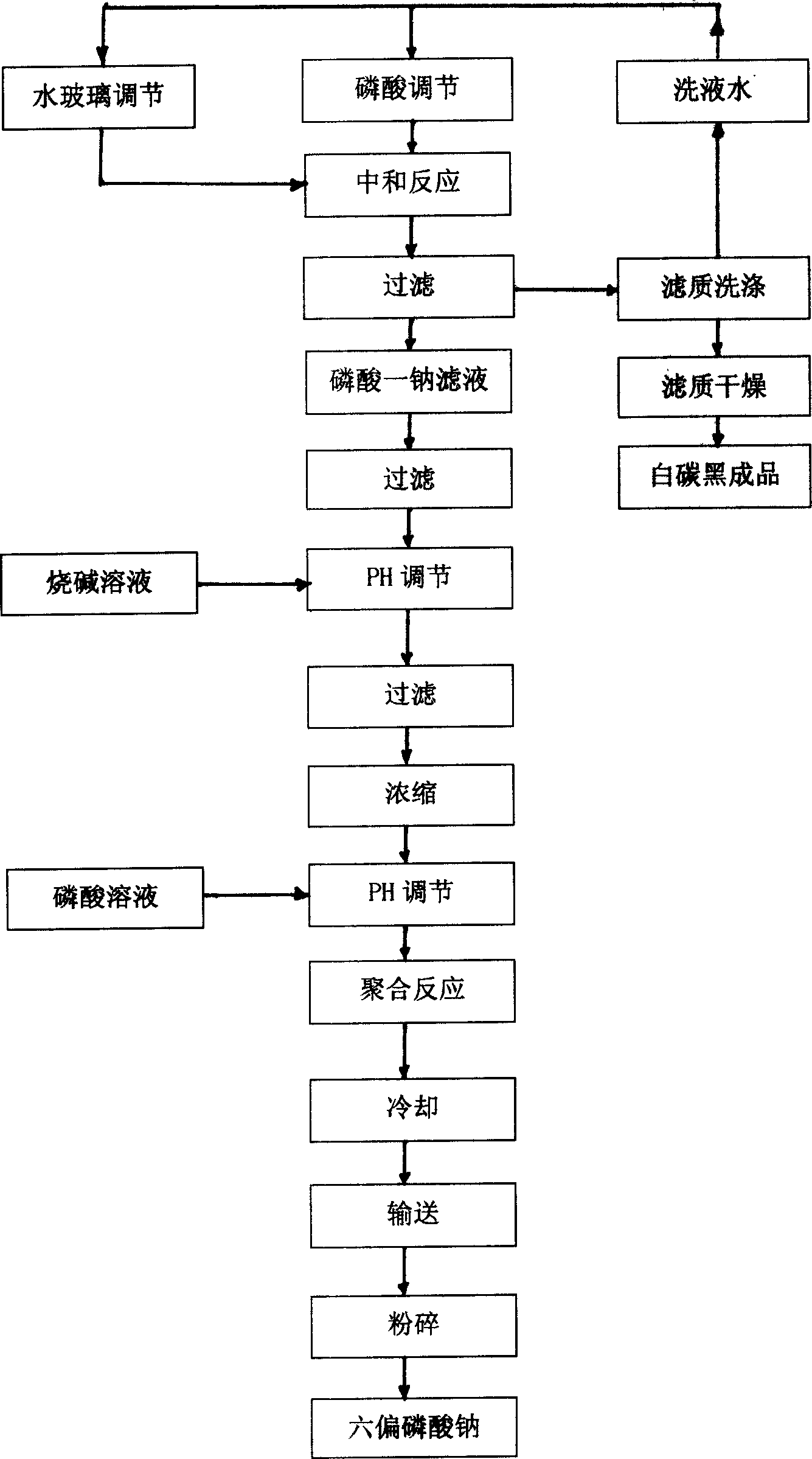

Method of preparation white carbon black and sodium bexameta phosphate

A technology of sodium hexametaphosphate and white carbon black, applied in chemical instruments and methods, phosphorus compounds, silicon dioxide, etc., can solve the problems of large environmental pollution, high product cost, and high impurity content, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: utilize the preparation method of 85% or 40% phosphoric acid

[0040] Preparation of phosphoric acid and water glass solution: put 4 tons of 85% phosphoric acid into the regulating tank, then start stirring, slowly add 4.5 tons of pure water to the regulating tank, stir for 20 minutes, and take a sample to measure its specific gravity should be 1.25g / cm 3 , when the specific gravity is qualified, pump the qualified phosphoric acid to the high metering tank of the neutralization post for use; if it is 40% phosphoric acid, it can be directly pumped to the high metering tank of the neutralization post for use; pump 40Be raw water Put 3 tons of glass into the water glass regulating tank, turn on the agitator, open the pure water valve, accurately add 4.1 tons of pure water into the regulating tank, stir for 10 minutes, and take a sample to measure its specific gravity should be 1.13g / cm 3 (17°Be), when the adjusted concentration is qualified, open the bottom d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com