Production method of electronic-grade hydrochloric acid

A production method and electronic-grade technology, applied in chemical instruments and methods, halogen/halogen acid, chlorine/hydrogen chloride purification, etc., can solve the problem of low product purity and achieve high product purity, simple equipment, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

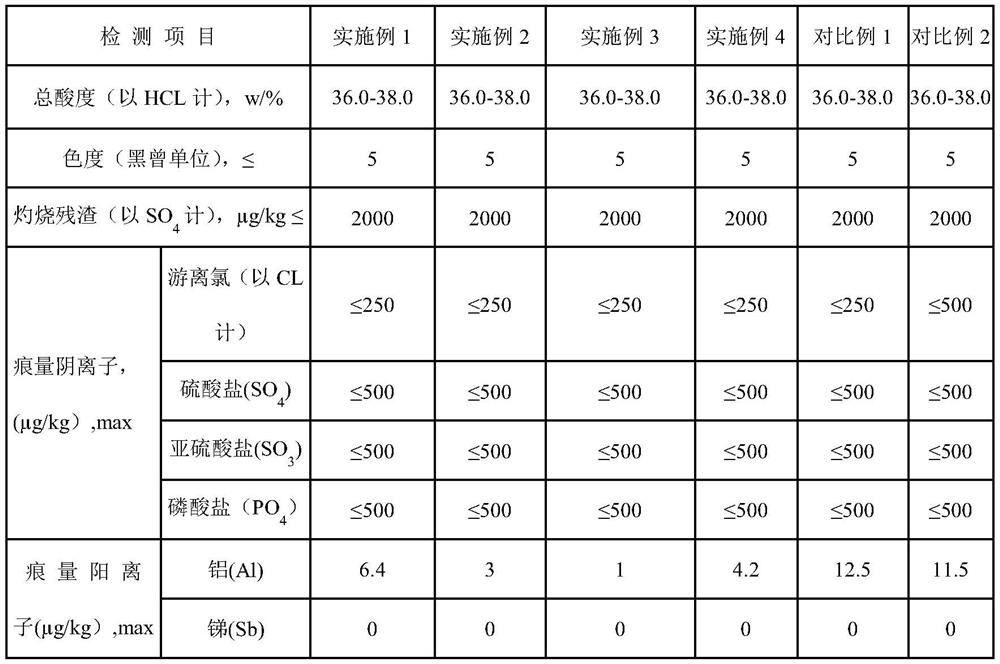

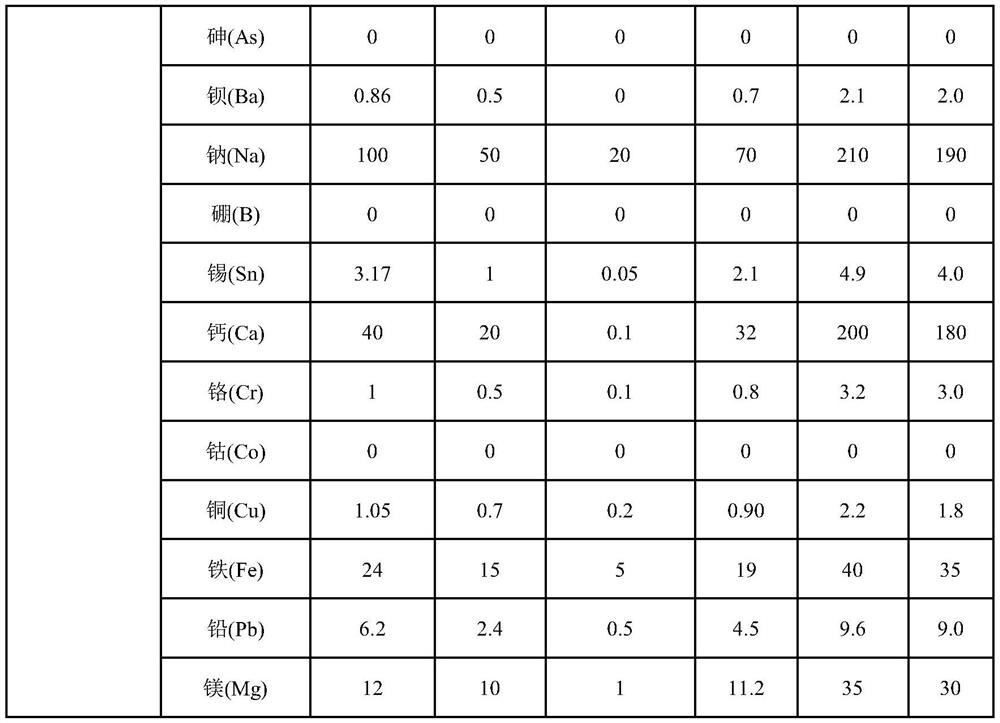

Embodiment 1

[0035] (1) Pass 500L of hydrogen chloride gas into the pre-washing tower with 100kg, 2% tin protochloride solution, and carry out washing and dechlorination.

[0036] (2) After dechlorination, pass through a rough washing tower with 100kg of reagent grade hydrochloric acid for rough washing, and after rough washing, pass through 5°C frozen brine and a demister to remove water vapor.

[0037] (3) After removing water vapor, enter the fine washing tower with 100kg of high-purity hydrochloric acid (EL grade). Pure water absorbs hydrogen chloride gas, and after the absorption reaches 37%, it passes through two-stage precision filters to obtain the finished product of electronic grade hydrochloric acid.

Embodiment 2

[0039] (1) Pass 500L of hydrogen chloride gas into the pre-washing tower with 100kg, 2% tin protochloride solution, and carry out washing and dechlorination.

[0040] (2) After dechlorination, pass through a rough washing tower with 100kg of reagent grade hydrochloric acid for rough washing, and after rough washing, go through -25°C frozen brine and a demister to remove water vapor.

[0041] (3) After removing water vapor, it enters the fine washing tower with 100kg of high-purity hydrochloric acid (EL grade). After fine washing, it is condensed again by -25°C frozen brine, and then the excess water is removed by a demister, and finally it is used in a circulating absorption tower. 18MΩ.cm ultra-pure water absorbs hydrogen chloride gas, and after the absorption reaches 37%, it passes through two-stage precision filters to obtain electronic grade hydrochloric acid products.

Embodiment 3

[0043] (1) Pass 500L of hydrogen chloride gas into the pre-washing tower with 100kg, 5% tin protochloride solution, and carry out washing and dechlorination.

[0044] (2) After dechlorination, pass through a rough washing tower with 100kg of reagent grade hydrochloric acid for rough washing, and after rough washing, go through -35°C frozen brine and a demister to remove water vapor.

[0045] (3) After removing water vapor, enter the fine washing tower with 100kg of high-purity hydrochloric acid (EL grade). After fine washing, it will be condensed through -35°C frozen brine again, and then use the demister to remove excess water, and finally pass through the hydrogen chloride circulation absorption tower. The gas, after absorbing up to 37%, passes through the two-stage precision filter to obtain the finished product of electronic grade hydrochloric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com