A kind of environment-friendly curing carbon felt and preparation method thereof

A carbon felt and environmentally friendly technology, applied in the field of environmentally friendly solidified carbon felt and its preparation, can solve the problems of high raw material prices, large environmental pollution, and large energy consumption, and achieve the effect of abundant raw material sources and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

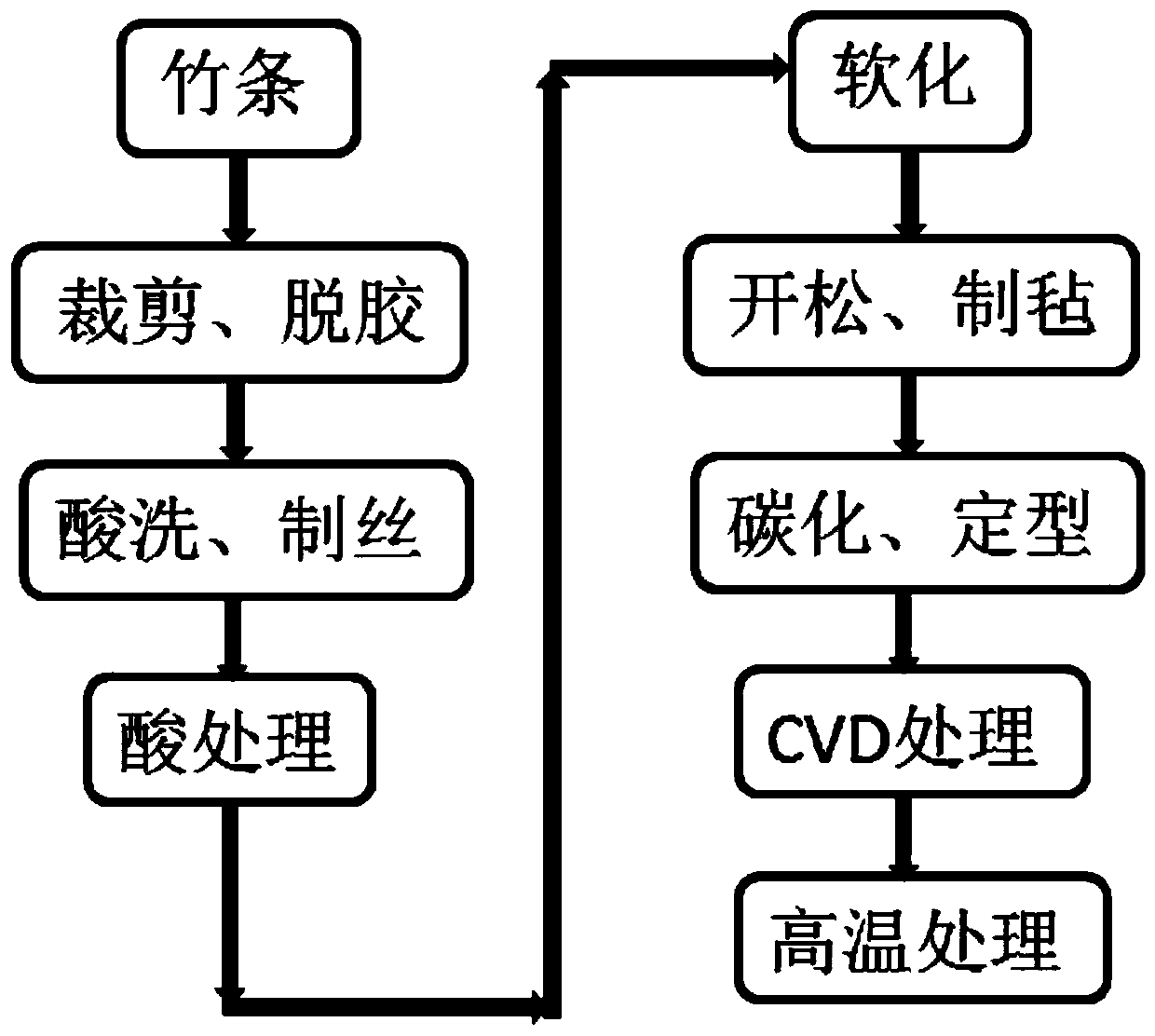

[0031] The present invention also proposes a kind of preparation method of environment-friendly curing carbon felt (referring to figure 1 ), including the following steps:

[0032] S1: Cutting and degumming, cutting the bamboo into bamboo strips with a length of 500-1500 mm and a width of 10-20 mm, then soaking the bamboo strips in a degumming agent for degumming, and then rinsing them with deionized water; cutting is In order to better degumming; degumming treatment is to remove the pectin, fat wax, etc. in the bamboo fiber.

[0033] S2: Pickling and silk making, soaking the bamboo sticks treated in step S1 in concentrated hydrochloric acid, then rinsing them with deionized water, and then making silk with the bamboo sticks with a hydraulic press to obtain bamboo silk; the acid Washing is to remove metal elements and inorganic elements in bamboo fibers, such as K, Na, S, P, etc.

[0034] S3: acid treatment, put the bamboo silk obtained in step S2 into the reaction tank, add...

Embodiment 1

[0053] The present embodiment provides a kind of preparation method of environment-friendly cured carbon felt, comprises the following steps:

[0054] S1: cutting and degumming, cutting the bamboo into bamboo strips with a length of 500mm and a width of 10mm, and then putting the bamboo strips into NaHCO with a concentration of 25% 3 solution, soak at 90°C for 3 hours, and then rinse with deionized water;

[0055] S2: pickling and silk making, put the bamboo strips treated in step S1 into concentrated hydrochloric acid with a mass fraction of 20% and soak for 20 minutes, then rinse them with deionized water, and then use a hydraulic press to make silk from the bamboo strips. get bamboo silk;

[0056] S3: acid treatment, put the bamboo filaments obtained in step S2 into the reaction tank, add the dilute hydrochloric acid with a mass fraction of 10%, heat to 80°C, pressurize to 1.5MPa, and then keep the temperature at 80°C and 1.5MPa. Pressing for 5h; washing the acid-treated ...

Embodiment 2

[0064] The present embodiment provides a kind of preparation method of environment-friendly cured carbon felt, comprises the following steps:

[0065] S1: cutting and degumming, the bamboo is cut into bamboo strips with a length of 850mm and a width of 14mm, and then the bamboo strips are put into a concentration of 30% Na 2 CO 3 solution, soak at 105°C for 3.5 hours, and then rinse with deionized water;

[0066] S2: pickling and silk making, put the bamboo strips treated in step S1 into concentrated hydrochloric acid with a mass fraction of 27% and soak for 27 minutes, then rinse them with deionized water, and then use a hydraulic press to make silk from the bamboo strips. get bamboo silk;

[0067] S3: acid treatment, put the bamboo filaments obtained in step S2 into the reaction tank, add the dilute hydrochloric acid with a mass fraction of 15%, heat to 60°C, pressurize to 1.6MPa, and then keep the temperature at 60°C and 1.6MPa. Pressing for 6 hours; washing the acid-tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com