Comprehensive treatment method and device of waste gas of ship on basis of seawater electrolysis

A comprehensive treatment and seawater technology, applied in seawater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high plasma energy consumption, high requirements for equipment anti-corrosion, excessive consumption, etc., and achieve reduction Ship safety hazards and additional investment costs, high-efficiency and rapid gas-phase oxidation, and the effect of improving system economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

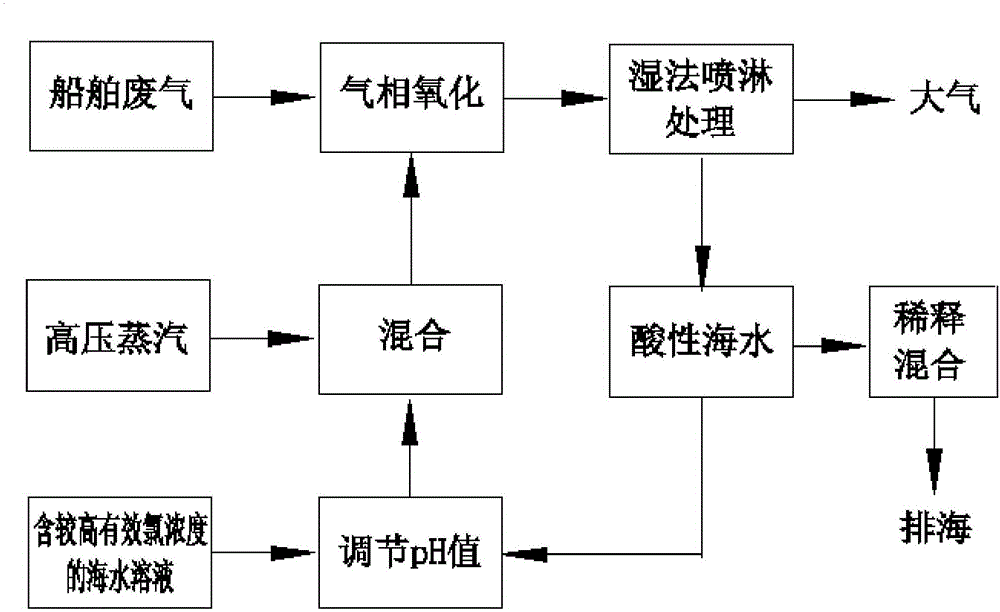

[0050] Such as figure 1 As shown, a comprehensive treatment method for ship exhaust gas based on electrolysis of seawater has the following steps:

[0051] S1. Preparation of seawater solution with high available chlorine concentration by seawater electrolysis without diaphragm, the main chemical reaction is as follows:

[0052] anode:

[0053] 2Cl - -2e→Cl 2 (l),

[0054] Cl 2 (l)+H 2 O→HCl+HClO,

[0055] HClO→ClO - +H + ,

[0056] 2HClO+ClO - →ClO 3 - +H + +Cl - ,

[0057] cathode:

[0058] 2H 2 O+2e→2OH - +H 2 (g),

[0059] Afterwards, it is mixed with an acidic seawater solution, which is a solution obtained after separation and purification of the waste liquid obtained after the wet spraying treatment. The acidic seawater solution is used to adjust the pH value of the seawater solution containing higher available chlorine concentration, and the range of the pH value is 2-6, so that the available chlorine in the seawater solution containing higher avai...

Embodiment 2

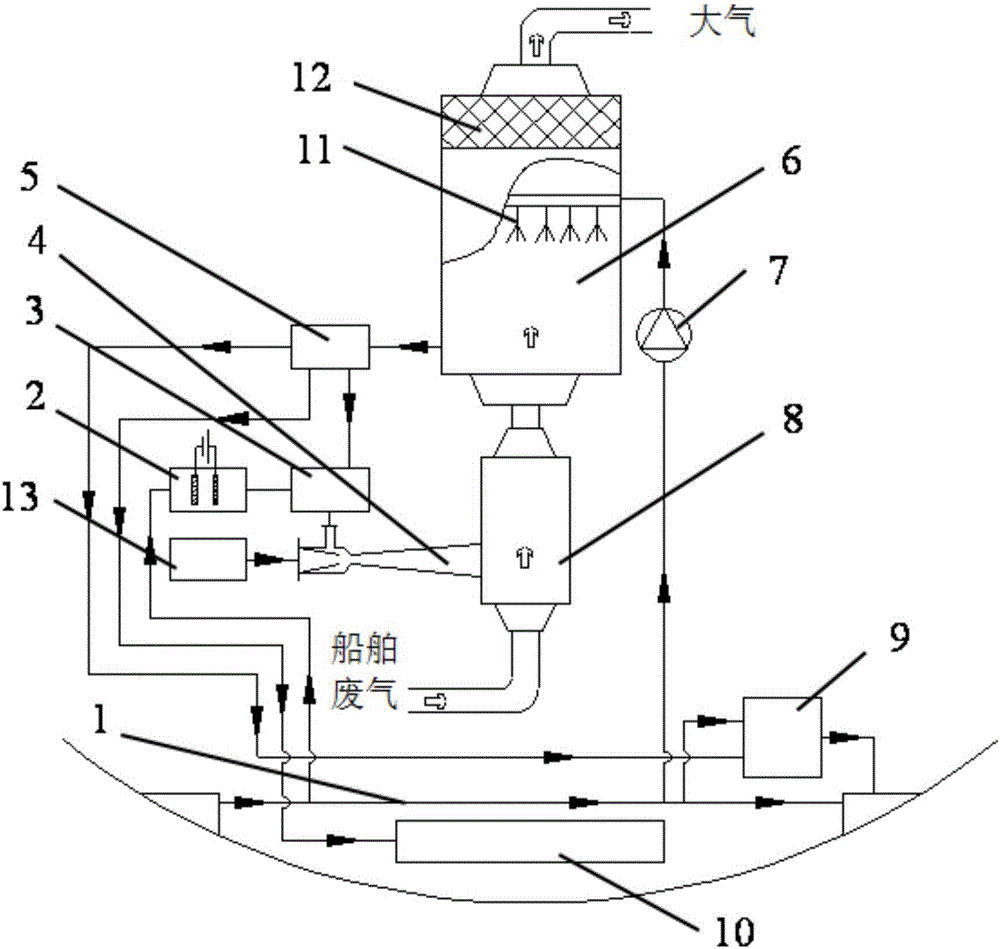

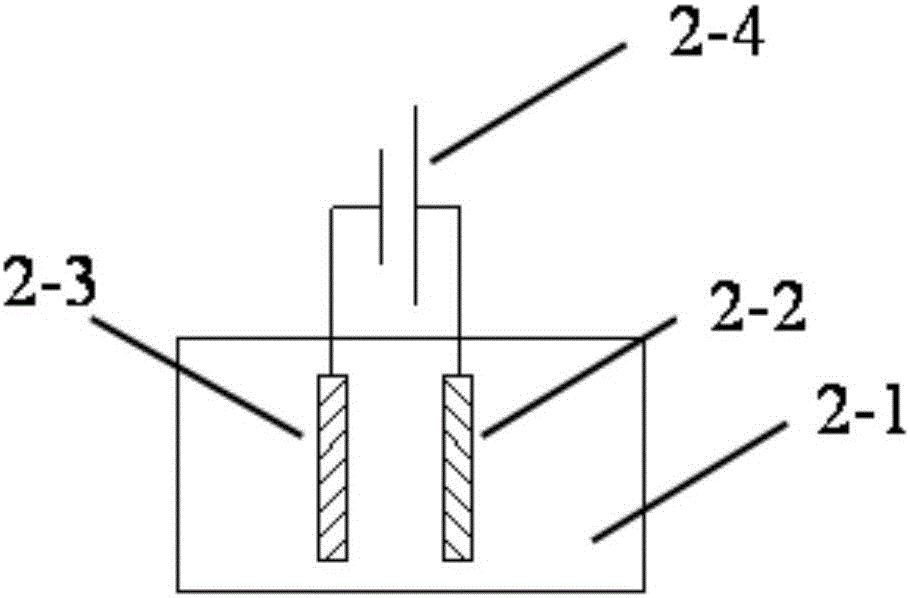

[0075] Such as Figure 2-4 As shown, a ship exhaust gas comprehensive treatment device based on electrolysis of seawater includes a main seawater pipe 1, an electrolysis seawater unit 2, a regulator 3, a steam jet mixer 4, a separation and purification device 5, a washing tower 6, and a seawater supply pump 7, Pre-oxidizer 8, dilution mixer 9 and sludge tank 10, spraying device 11 and demisting device 12 are arranged in the said washing tower 6,

[0076] Natural seawater enters the electrolytic seawater unit 2 through the main seawater pipe 1, and the obtained seawater solution containing a relatively high concentration of available chlorine is mixed with the acidic seawater produced by the separation and purification device 5 in the regulator 3, and then, Enter the steam jet mixer 4 and mix with the surplus high-pressure steam of the ship boiler discharged from the ship boiler 13, and enter the pre-oxidizer 8 to mix and react with the ship exhaust gas, and the obtained flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com