Low-heat low-smoke flame retardant and application thereof in preparing flame-retardant master batch

A technology of low-smoke flame retardant and flame-retardant masterbatch, which is used in the application field of low-heat and low-smoke flame retardants and the preparation of flame-retardant masterbatches, can solve the problems of not being used as an evaluation material, etc., to reduce the heat release rate, delay the The spread of fire, the effect of increasing the chance of escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A new type of low-heat and low-smoke flame retardant, the weight percentage of each component is: 45% of aluminum hypophosphite, 30% of melamine cyanurate, 10% of nano diatomite, and 15% of polydiisopropylbenzene.

[0035] Blend manufacturing process, after the ingredients are mixed, they are added to a co-rotating twin-screw extruder for extrusion and granulation. The screw length-to-diameter ratio of the extruder can be 40, and the pellets are drawn and pelletized after water-cooling with a pull rod. The temperature setting of each zone of the twin-screw extruder is 170°C-180°C-180°C-190°C-190°C-190°C-200°C-190°C. The temperature of the cooling water was controlled at 30° C., the blend B was obtained by melt extrusion, granulation and cooling.

Embodiment 2

[0037] A new type of low-heat and low-smoke flame retardant, the weight percentage of each component is: 40% of aluminum hypophosphite, 50% of melamine cyanurate, 4% of nano diatomite, and 6% of polydiisopropylbenzene.

[0038] The flame retardant masterbatch using the above new type of flame retardant, the weight percentage of each component is: 85% of new low heat and low smoke flame retardant, 12% of polypropylene, 2% of polyethylene wax, and 1% of antioxidant (1010) .

[0039] Polypropylene (homopolymerization, Moplen HP550, produced by Basell Company) and the flame-retardant masterbatch were blended and extruded in a twin-screw extruder for granulation, wherein the weight ratio was polypropylene / flame-retardant masterbatch=97.65 / 2.35. See Comparative Example 1 for the test of CONE. This blend is C.

[0040] The manufacturing process of flame retardant masterbatch includes the following steps: mixing a new type of low heat and low smoke flame retardant, carrier resin, an...

Embodiment 3

[0042] A new type of low-heat and low-smoke flame retardant, the weight percentage of each component is: 70% of calcium hypophosphite, 23% of melamine polyphosphate, 2% of nano silicon dioxide, and 5% of dimethyl diphenylhexane.

[0043] The flame retardant masterbatch using the above new type of flame retardant, the weight percentage of each component is: 40% of new low heat and low smoke flame retardant, 57.9% of polypropylene, 2% of polyethylene wax, and 0.1% of antioxidant (1010) .

[0044] Adopting polypropylene (homopolymerization, Moplen HP550, produced by Basell) and the flame-retardant masterbatch in a twin-screw extruder to co-extrude and pelletize, wherein the weight ratio is polypropylene / fire-retardant masterbatch=95 / 5, manufacturing Technology is with embodiment 2. See Comparative Example 1 for the test of CONE. This blend is D.

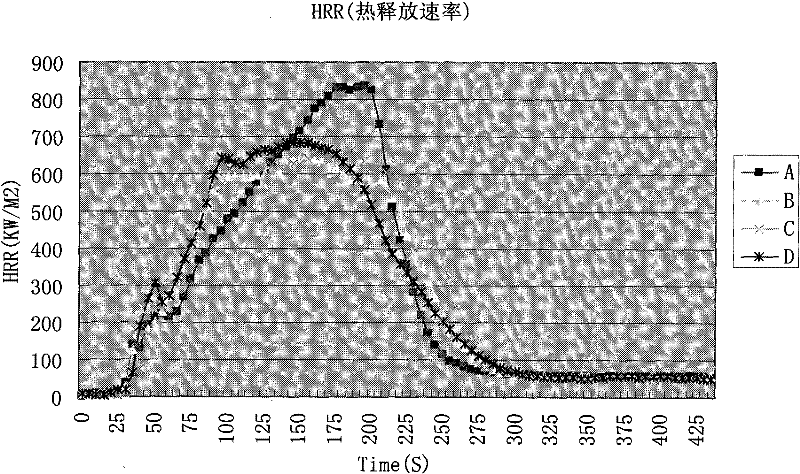

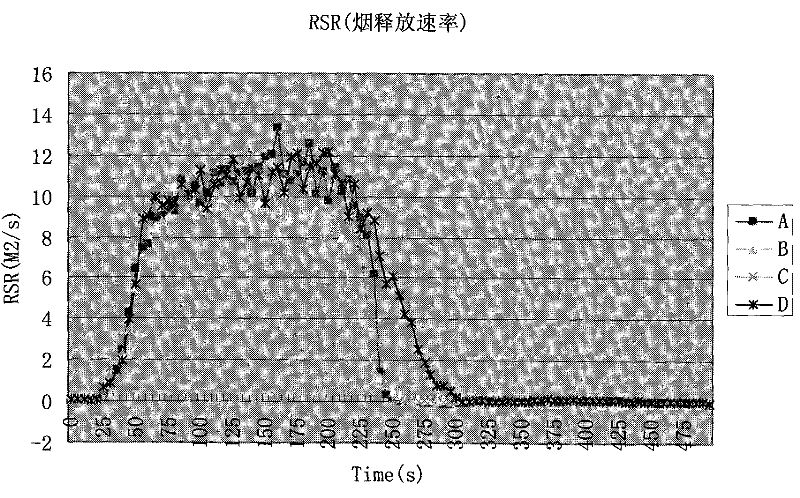

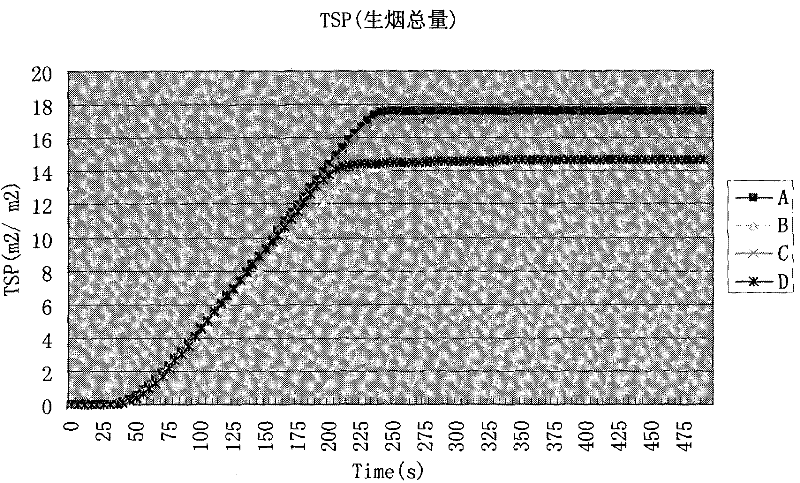

[0045] Using CONE to test heat release rate (HRR), smoke release rate (RSR), total smoke production (TSP), and other basic performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com