Composite utilization system for waste heat of exhaust fume of boiler

A flue gas waste heat and boiler technology, which is applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc. Coal consumption rate and the effect of improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

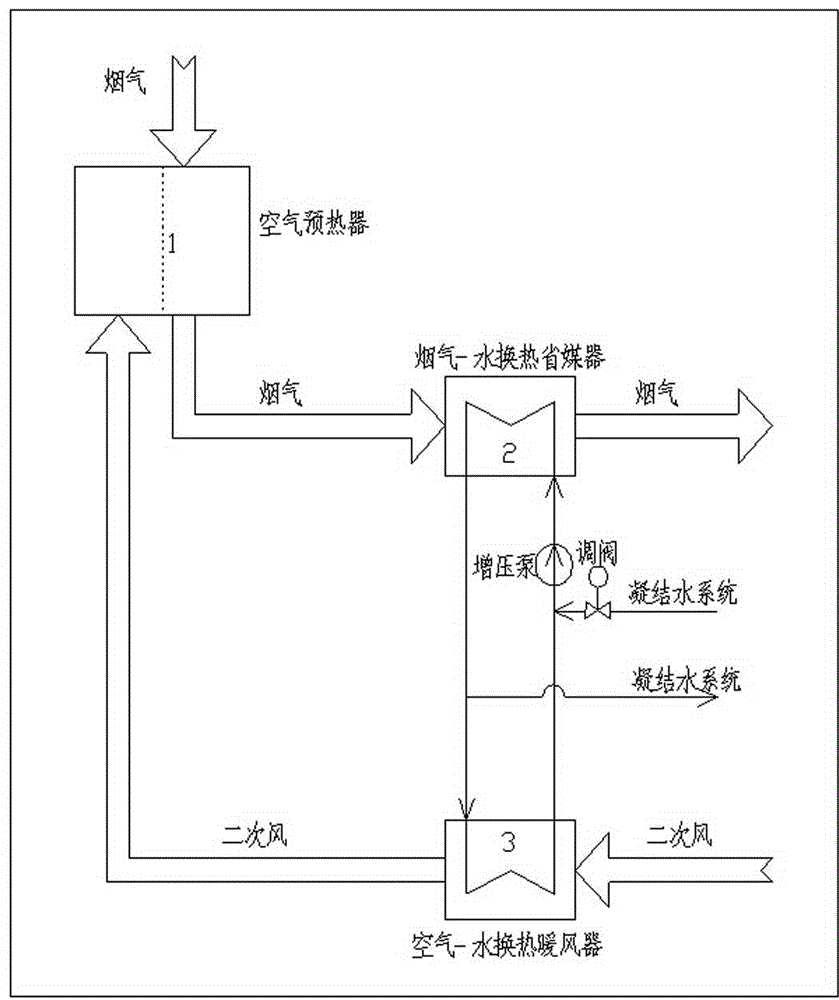

[0019] figure 1 As shown, the system of the present invention mainly includes three main equipments: air preheater (1), flue gas-water heat exchange economizer (2) and air-water heat exchange heater (3), as well as the mutual connect.

[0020] Taking a million-dollar power plant as an example, through the flue gas-water heat exchanger (2), the heat of the flue gas at the outlet of the air preheater (1) is absorbed, the exhaust gas temperature is reduced from 157°C to 90°C, and the temperature of the water medium is reduced from Heating from 70°C to 120°C. The 120°C hot water at the outlet of the flue gas-water heat exchanger (2) is used to heat the secondary air before the inlet of the air preheater (1), heating the secondary air from 25°C to 100°C, and the remaining heat is used for heating Condensate in steam turbine recuperation system. :

[0021] Taking a million-dollar power plant as an example, according to preliminary calculations, the standard coal consumption for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com