Self adaptive lead-free solder component and preparation method thereof

A lead-free solder, self-adaptive technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of poor wettability, increased cost, and small effect, and achieve the effect of tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

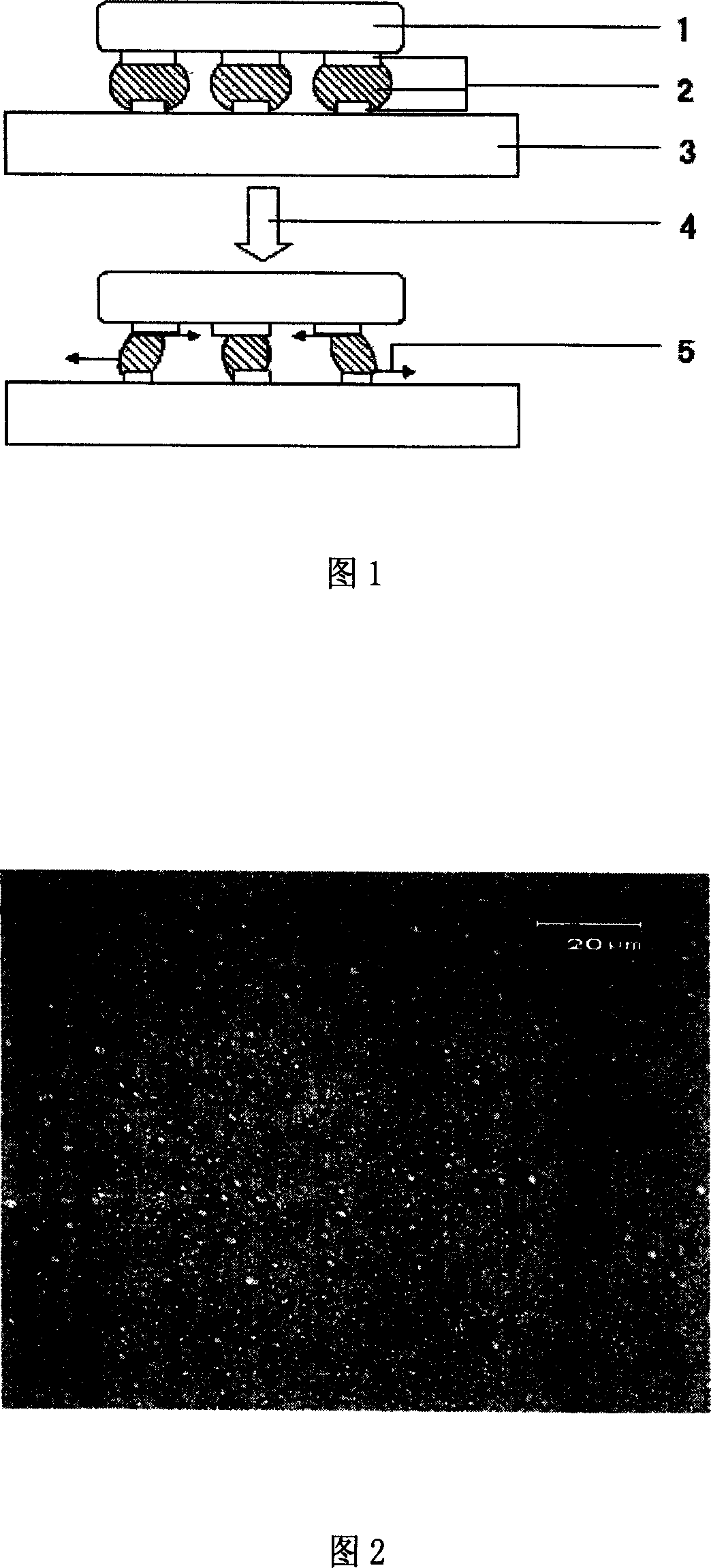

Method used

Image

Examples

Embodiment 1

[0015] The tin, silver and zinc with a purity of 99.99% are heated to 1200°C in a vacuum melting furnace under the protection of argon in a mass ratio of 95.4:3.7:0.9, and are magnetically stirred at the same time to make the alloy composition uniform, and then water-cooled and solidified . Then turn the alloy over and reheat to 1200°C to melt, while magnetic stirring and water cooling. This is repeated at least five times to obtain a button-shaped tin-silver-zinc lead-free solder with a diameter of about 3.0-3.5cm; put the tin-silver-zinc lead-free solder into a crucible under vacuum protection and heat it to 230°C, and quickly pass it through Water quenching can generate silver-zinc thermoelastic martensite in the solder, so that it has a two-way shape memory effect between 20°C and 100°C, and a tin-silver-zinc self-adaptive lead-free solder with shape memory performance is obtained. The micrometallography of the self-adaptive lead-free solder obtained after preparation is ...

Embodiment 2

[0017] Heat tin, silver, zinc and indium with a purity of 99.99% in a mass ratio of 94.9:3.7:0.9:0.5 in a vacuum melting furnace under the protection of argon to 1300°C for melting, and at the same time add magnetic stirring to make the alloy composition uniform , and then freezes. Then turn the alloy over and reheat to 1300°C to melt, while magnetic stirring and water cooling. This is repeated at least five times to obtain a button-shaped tin-silver-zinc lead-free solder with a diameter of about 3.0-3.5cm; put the tin-silver-zinc lead-free solder into a crucible under vacuum protection and heat it to 250°C, and quickly pass it through Water quenching can generate silver-zinc thermoelastic martensite in the solder, so that it has a two-way shape memory effect between 30°C and 110°C, and a tin-silver-zinc self-adaptive lead-free solder with shape memory performance is obtained. The micrometallography of the self-adaptive lead-free solder obtained after preparation is shown in ...

Embodiment 3

[0019] The tin, silver and zinc with a purity of 99.99% are heated to 1350°C in a vacuum melting furnace under the protection of argon in a mass ratio of 96.1:3.4:0.5, and magnetically stirred at the same time to make the alloy composition uniform, and then water-cooled and solidified . Then turn the alloy over and reheat to 1350°C to melt, while magnetic stirring and water cooling. This is repeated at least five times to obtain a button-shaped tin-silver-zinc lead-free solder with a diameter of about 3.0-3.5cm; put the tin-silver-zinc lead-free solder into a crucible under vacuum protection and heat it to 255°C, and quickly pass it through Water quenching can generate silver-zinc thermoelastic martensite in the solder, so that it has a two-way shape memory effect between 35°C and 115°C, and a tin-silver-zinc self-adaptive lead-free solder with shape memory performance is obtained. The micrometallography of the self-adaptive lead-free solder obtained after preparation is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com