Manufacturing method of nickel-titanium alloy component, and nickel-titanium alloy component

A nickel-titanium alloy and manufacturing method technology, applied in the field of shape memory alloys, can solve problems such as poor universality, high structural design requirements, inability to achieve high energy absorption, convenient transportation, strong universality, self-recovery shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The manufacturing method of the nickel-titanium alloy member of the present embodiment comprises the following steps:

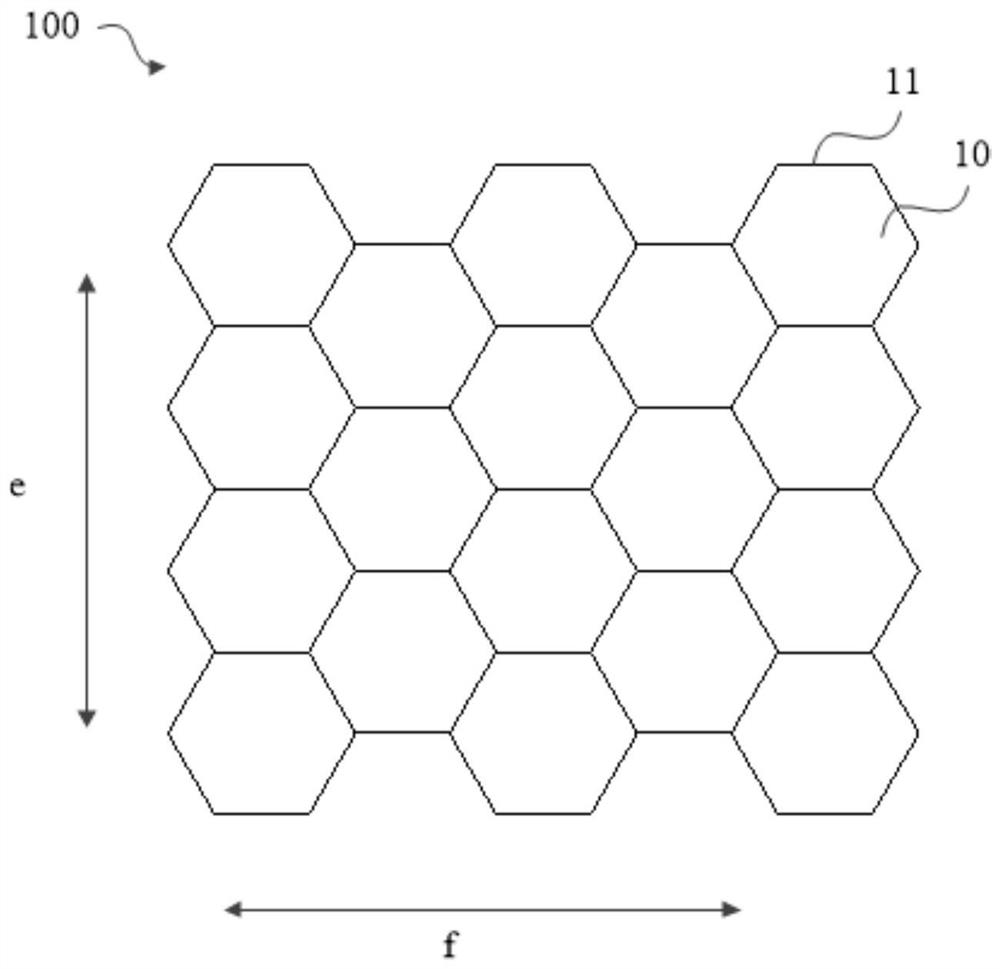

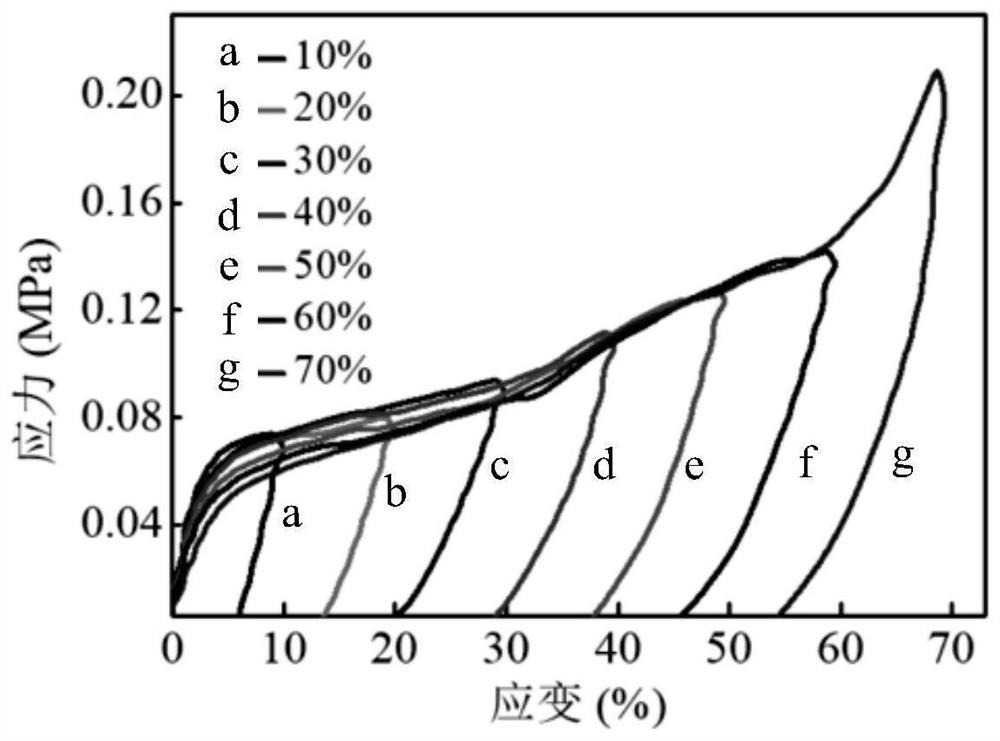

[0074] 1) Use Solidworks software to build a hexagonal honeycomb structure composed of hexagonal unit cells with a side length of 11mm and a wall thickness of 0.4mm arranged in 5×4. The height of the honeycomb structure along the printing direction is 10mm. Use the MaterializeMagics software to process the constructed model layer by layer, and then use the 3D printing filling software to set the printing parameters and strategies for each layer, obtain the printing process parameters of the model, and import them into the computer of the selective laser melting equipment.

[0075] 2) Take Ni after vacuum drying at 100°C for 8 hours 50.6 Ti 49.4Alloy powder (with a particle size distribution of 15-53 μm) is evenly spread on the nickel-titanium substrate, the substrate is pre-heated to 180°C, and the inert gas argon is introduced into the selective lase...

Embodiment 2

[0081] The manufacturing method of the nickel-titanium alloy member of the present embodiment comprises the following steps:

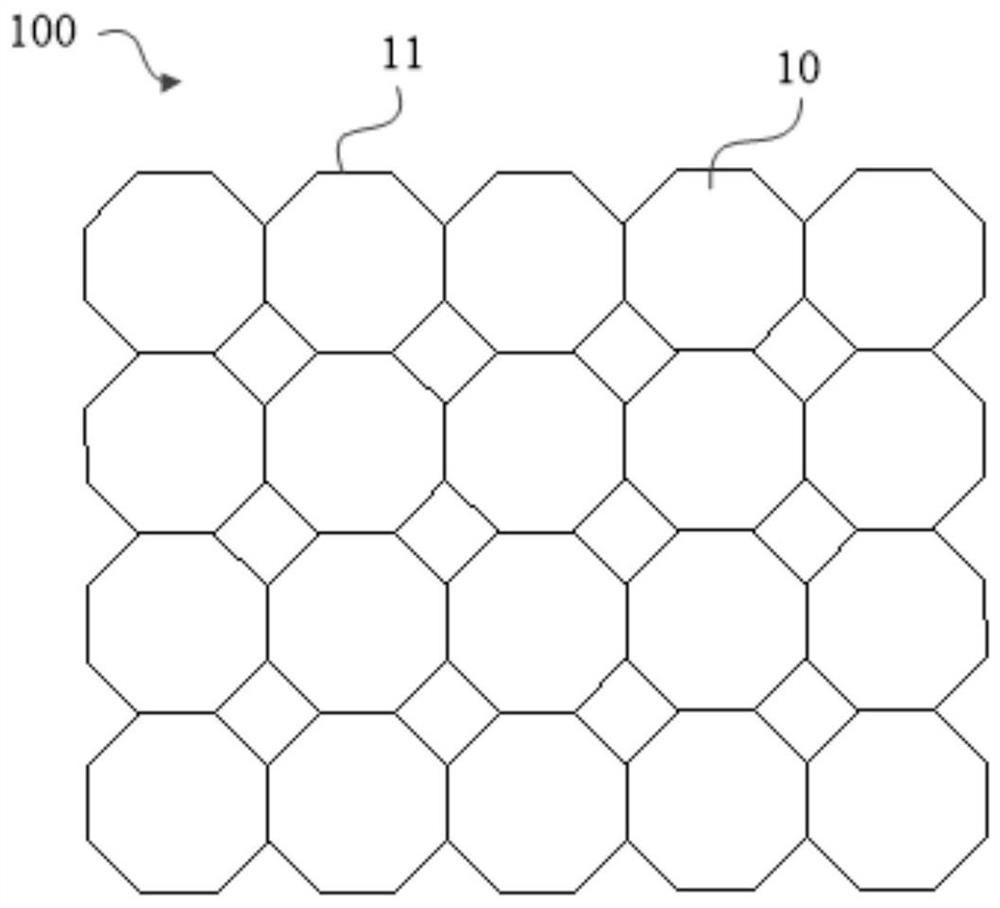

[0082] 1) Use Solidworks software to build a three-dimensional lattice structure composed of 4×4×4 octahedral unit cells with a rod diameter of 10 mm and a rod diameter of 0.4 mm, and use Materialize Magics software to analyze the constructed model. Layer processing, and then use the 3D printing filling software to set the printing parameters and strategies of each layer, obtain the printing process parameters of the model, and import them into the computer of the selected laser melting equipment.

[0083] 2) Take Ni after vacuum drying at 100°C for 8 hours 50.6 Ti 49.4 Alloy powder (with a particle size distribution of 15-53 μm) is evenly spread on the nickel-titanium substrate, the substrate is pre-heated to 180°C, and the inert gas argon is introduced into the selective laser melting equipment until the oxygen content in the chamber is below 500ppm...

Embodiment 3

[0087] The manufacturing method of the nickel-titanium alloy member of the present embodiment comprises the following steps:

[0088] 1) Use Solidworks software to construct a 5×5 triangular honeycomb structure composed of triangular unit cells with a side length of 10mm and a wall thickness of 0.4mm. The printing and filling software sets the printing parameters and strategies of each layer, obtains the printing process parameters, and imports them into the computer of the selected laser melting equipment.

[0089] 2) Take Ni after vacuum drying at 100°C for 8 hours 50.6 Ti 49.4 Alloy powder (with a particle size distribution of 15-53 μm) is evenly spread on the nickel-titanium substrate, the substrate is pre-heated to 180°C, and the inert gas argon is introduced into the selective laser melting equipment until the oxygen content in the chamber is below 500ppm; Spread powder on the substrate in a cyclical manner, and then laser melt until the last layer is processed and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com