Self-repair material and article with shape memory effect and preparation method thereof

A technology of self-healing materials and memory effects, which is applied in the field of self-healing materials and their preparation, can solve the problems of limited application, few research reports on self-healing of shape memory materials, and lack of self-healing functions. The effect of diversified methods and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

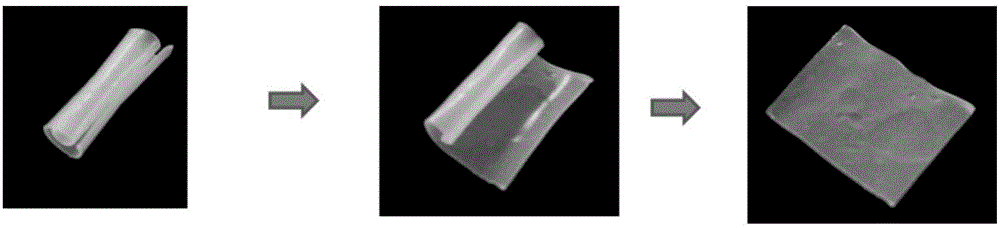

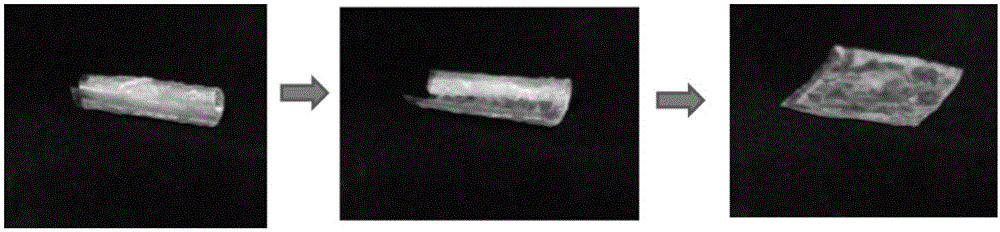

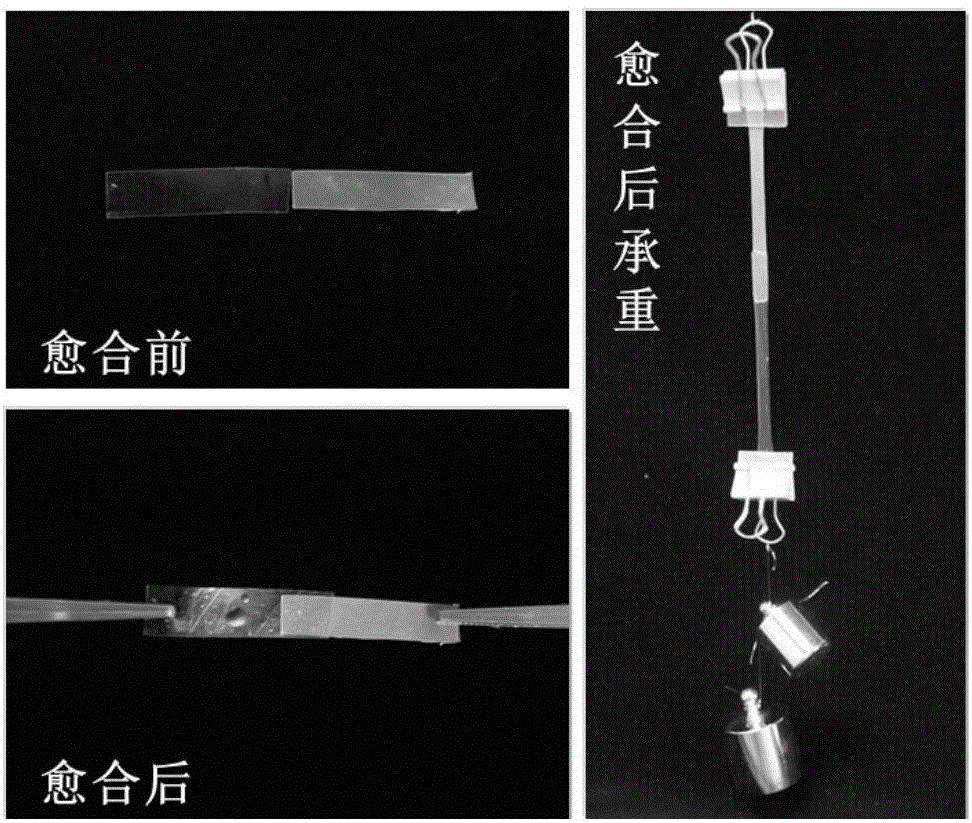

Embodiment 1

[0058] Weigh 20g of polylactic acid (PLA) and dissolve it in 60ml of chloroform under magnetic stirring. When a homogeneous transparent system is formed, add 80g of sodium chloride (as a porogen) to the system, mix well, and cast to form a film. After drying for 48 hours at room temperature, take it out and dry it in vacuum for 24 hours, then soak the film in ultrapure water for 2 hours, rinse it with ultrapure water, repeat this step three times, and then dry the film at room temperature to obtain a polymer with a microporous structure inside. Lactic acid shape memory polymers (ie, self-healing materials with shape memory effects). The self-healing material with shape memory effect described in the present invention has a porosity of 85%, a glass transition temperature of Tg=60°C, a shape fixation rate of 90%, and a shape recovery rate of 92%. The self-repair time is 10min.

Embodiment 2

[0060] Weigh 10g of ethylene-vinyl acetate copolymer (EVA, Sigma), add it to water, and form an emulsion with a solid content of 30%, put the above emulsion into a freeze-drying device and dry for 72h, and obtain the present invention. A self-healing material with shape memory effect, the self-healing material has a microporous structure inside, the porosity is 90%, the glass transition temperature is Tg=40°C, the shape fixation rate is 91%, and the shape recovery rate is 90%, The repair time of the self-healing material at 60° C. is 15 minutes.

Embodiment 3

[0062] 3 g of polyglycolic acid (PGA) was added to 20 g of dimethylamide (DMF), and mechanically stirred until the solution was transparent and an electrospinning solution was obtained. The prepared spinning solution is packed into the liquid storage device, a spinning voltage of 20KV is applied between the spinning needle and the receiving device, the spinning distance between the spinning needle and the receiving aluminum foil is controlled to be 13cm, and the flow rate of the polymer solution is adjusted to 0.01mL / min, the inner diameter of the spinning needle is 0.9mm, the spinning temperature is 25°C, and the air humidity is 53%. The self-healing material with shape memory effect of the present invention is obtained by electrospinning technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com