Method for preparing cellulose-based aerogel by bidirectional gradient

A cellulose and gel technology, applied in the fields of packaging engineering, new materials, forestry engineering, and natural polymers, can solve problems such as unfavorable elastic recovery of aerogels, and achieve the effects of controllable size, simple guiding equipment and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

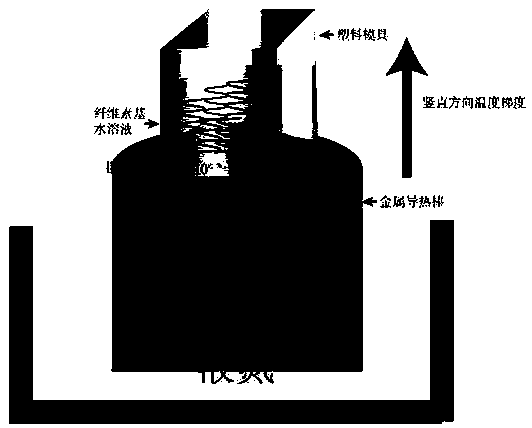

[0017] (1) Make a cylindrical polydimethylsiloxane wedge with a diameter of 2 cm and an inclination angle of 15° and place it on the bottom of a polyethylene plastic mold, place the plastic mold on a copper heat-conducting rod, and place the copper heat-conducting rod in the liquid in a nitrogen container.

[0018] (2) Take 20mL of TEMPO oxidized cellulose aqueous solution with a concentration of 0.3% and stir it evenly, and add it into the plastic mold.

[0019] (3) Add enough liquid nitrogen to the liquid nitrogen container until the cellulose in the mold is frozen and formed.

[0020] (4) Put the frozen cellulose solid block and mold into a freeze dryer and dry for 2 days.

[0021] (5) Release the mold after drying to obtain regular honeycomb structure cellulose airgel.

Embodiment 2

[0023] (1) Make a rectangular polyethylene wedge with a length and width of 5×5 cm and an inclination angle of 30° and place it on the bottom of the acrylic plastic mold. Place the plastic mold on the iron heat-conducting rod, and place the iron heat-conducting rod in a liquid nitrogen container.

[0024] (2) Take 50mL of mechanically ground cellulose aqueous solution with a concentration of 0.5% and stir it evenly, and add it into the plastic mold.

[0025] (3) Add enough liquid nitrogen to the liquid nitrogen container until the cellulose in the mold is frozen and formed.

[0026] (4) Put the frozen cellulose solid block and mold into a supercritical dryer and dry for 3 days.

[0027] (5) Release the mold after drying to obtain regular honeycomb structure cellulose airgel.

Embodiment 3

[0029] (1) Make a rectangular foam wedge with a length and width of 3×5 cm and an inclination angle of 20° and place it on the bottom of a polycarbonate plastic mold, place the plastic mold on an alloy heat conducting rod, and place the alloy heat conducting rod in a liquid nitrogen container .

[0030] (2) Take 50mL of cellulose / hydroxyethyl methacrylate aqueous solution with a concentration of 1% and stir evenly. The mass ratio of cellulose and hydroxyethyl methacrylate is 8:1, and add it to the plastic mold .

[0031] (3) Add enough liquid nitrogen to the liquid nitrogen container until the cellulose in the mold is frozen and formed.

[0032] (4) Put the frozen cellulose solid block and mold into a freeze dryer and dry for 3 days.

[0033] (5) After drying, the cellulose-based airgel with a regular honeycomb structure was obtained by demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com