Simple preparation method of hollow hydroxide derived from MOFs

A hydroxide, a simple technology, applied in the direction of nickel oxide/nickel hydroxide, cobalt oxide/cobalt hydroxide, etc., can solve the problems of high thermal decomposition temperature, energy waste, easy sintering and growth of material grains, and achieve Mild preparation conditions, rich preparation methods, and universal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

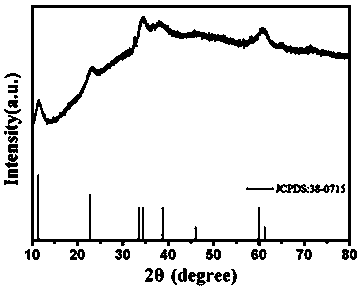

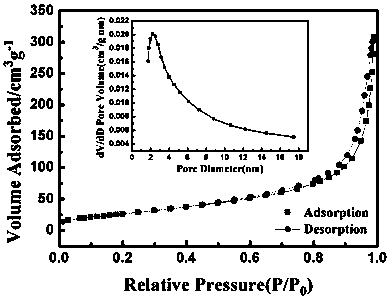

Embodiment 1

[0026] (a) 0.4366g Co(NO 3 ) 2 6H 2 O was dissolved in 3mL of methanol solution, 5.5828g of 2-methylimidazole was dissolved in 20mL of methanol solution, and then the two solutions were mixed, stirred at room temperature for 6h, then centrifuged, washed with ethanol, and dried to obtain diamond-shaped twelve Hedra ZIF-67;

[0027] (b) Disperse ZIF-67 in 0.1mol / L NaOH ethanol solution and let stand at room temperature for 6h, then centrifuge, wash with water / ethanol three times, and dry to obtain ZIF-67@Co(OH) 2 ;

[0028] (c) ZIF-67@Co(OH) 2 Disperse in a mixed solution of ethanol and water, stir and reflux in an oil bath at 90°C for 1 hour to remove excess ZIF-67, then centrifuge, wash with alcohol, and dry to obtain a porous / hollow structure of Co(OH) 2 Material.

Embodiment 2

[0030] (a) 0.4366g Co(NO 3 ) 2 6H 2 O was dissolved in 3mL of methanol solution, 5.5828g of 2-methylimidazole was dissolved in 20mL of methanol solution, and then the two solutions were mixed, stirred at room temperature for 6h, then centrifuged, washed with ethanol, and dried to obtain diamond-shaped twelve Hedra ZIF-67;

[0031] (b) 100mg Ni(NO 3 ) 2 6H 2 O was dissolved in 100 mL ethanol, then 100 mg ZIF-67 polyhedron was added to the above solution, and the suspension was slowly stirred at room temperature for 12 h, and Ni 2+ After the exchange, centrifuge, wash with alcohol several times, and dry at 50°C to obtain Co / Ni-MOF;

[0032] (c) Disperse Co / Ni-MOF in 0.1mol / L NaOH ethanol solution and let it stand at room temperature for 6h, then centrifuge, wash with water / ethanol three times, and dry to obtain MOFs@Co(OH) 2 / Ni(OH) 2 ;

[0033] (d) MOFs@Co(OH) 2 / Ni(OH) 2 Disperse in a mixed solution of ethanol and water, stir and reflux in an oil bath at 90°C for ...

Embodiment 3

[0035] (a) 0.4366g Co(NO 3 ) 2 6H 2 O was dissolved in 3mL of methanol solution, 5.5828g of 2-methylimidazole was dissolved in 20mL of methanol solution, and then the two solutions were mixed, stirred at room temperature for 6h, then centrifuged, washed with ethanol, and dried to obtain diamond-shaped twelve Hedra ZIF-67;

[0036] (b) 100mg Ce(NO 3 ) 3 6H 2O was dissolved in 100 mL of ethanol, and then 100 mg of ZIF-67 polyhedron was added to the above solution. The suspension was stirred slowly at room temperature for 12 h, and with Ce 3+ After exchange, centrifuge, wash with alcohol several times, and dry at 50°C to obtain Co / Ce-MOF;

[0037] (c) Disperse Co / Ce-MOF in 0.1mol / L NaOH ethanol solution and let it stand at room temperature for 6h, then centrifuge, wash with water / ethanol three times, and dry to obtain MOFs@Co(OH) 2 / Ce(OH) 3 ;

[0038] (d) MOFs@Co(OH) 2 / Ce(OH) 3 Disperse in a mixed solution of ethanol and water, stir and reflux in an oil bath at 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com