Method for manufacturing damping structural piece of aviation engine supporting system

A technology of aero-engine and damping structure, applied in the direction of high internal friction spring, etc., can solve the problems of insufficient bearing capacity, slow response, etc., and achieve the effect of regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

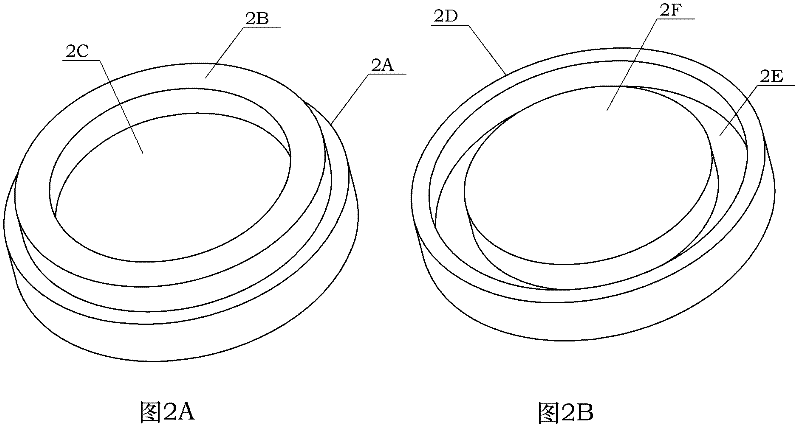

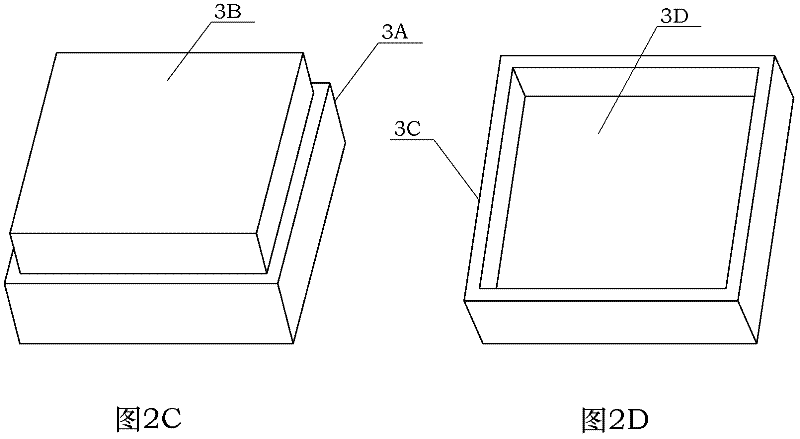

[0046] A Ti-50.3% Ni shape memory alloy wire is used to prepare an aero-engine rotor support damping structure (or metal rubber) with shape memory effect and variable stiffness performance. The damping structure is in the shape of a column, such as Figure 4 , Figure 5 As shown, the mold for making the damping structure is as follows Figure 2C , Figure 2D , Figure 2E shown.

[0047] Step 1: Wind the Ti-50.3%Ni shape memory alloy wire into a memory alloy spring wire; the processing temperature is 26°C; the wire diameter of the Ti-50.3%Ni shape memory alloy wire is 0.2mm; it is made on the spring making equipment The memory alloy spring wire has a pitch of 0, a helix diameter of 1.4mm, and a single length of 60cm.

[0048] Step 2: Pre-heat-setting the memory alloy spring wire to obtain a spring wire preform; the pre-heat-setting temperature is 500° C., and the pre-heat-setting time is 5 minutes.

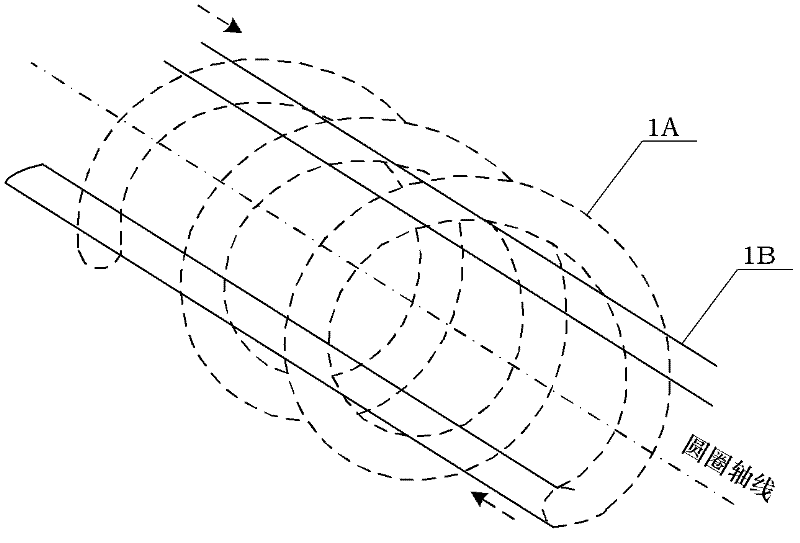

[0049] Step 3: Stretch, wind and cold mold the spring wire preform to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com