Battery electrode, preparation method of battery electrode and hybrid energy storage device

A technology for battery electrodes and composite carbon, which is applied in battery electrodes, electrode manufacturing, electrode current collector coating, etc. It can solve the problems of large transition metal oxides, decreased battery capacity, poor dispersion, etc., and achieve excellent cycle stability. and rate performance, low capacity decay rate, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

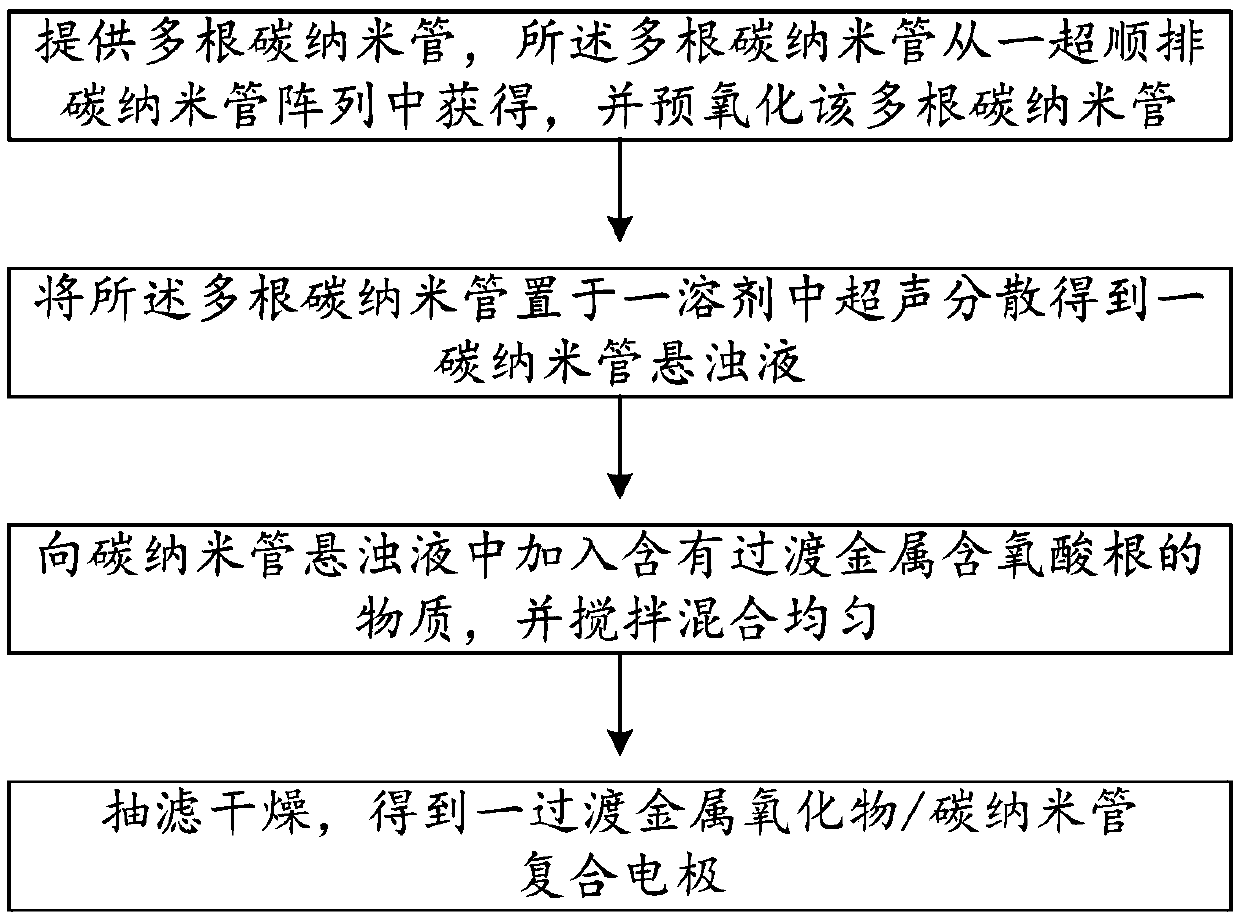

[0036] see figure 1 , the embodiment of the present invention also provides the preparation method of the battery electrode, which specifically includes the following steps:

[0037] S1, providing a plurality of carbon nanotubes, the plurality of carbon nanotubes are obtained from a super-aligned carbon nanotube array, and preoxidizing the plurality of carbon nanotubes;

[0038] S2, ultrasonically dispersing the plurality of carbon nanotubes in a solvent to obtain a suspension of carbon nanotubes;

[0039] S3, adding a substance containing a transition metal oxyacid group to the carbon nanotube suspension, and stirring and mixing evenly;

[0040] S4, sucking and drying to obtain a transition metal oxide / carbon nanotube composite electrode.

[0041] Steps S1 to S4 will be described in detail below.

[0042] In step S1, a plurality of carbon nanotubes are provided, and the plurality of carbon nanotubes are obtained from a super-aligned carbon nanotube array, and the plurality...

Embodiment 1

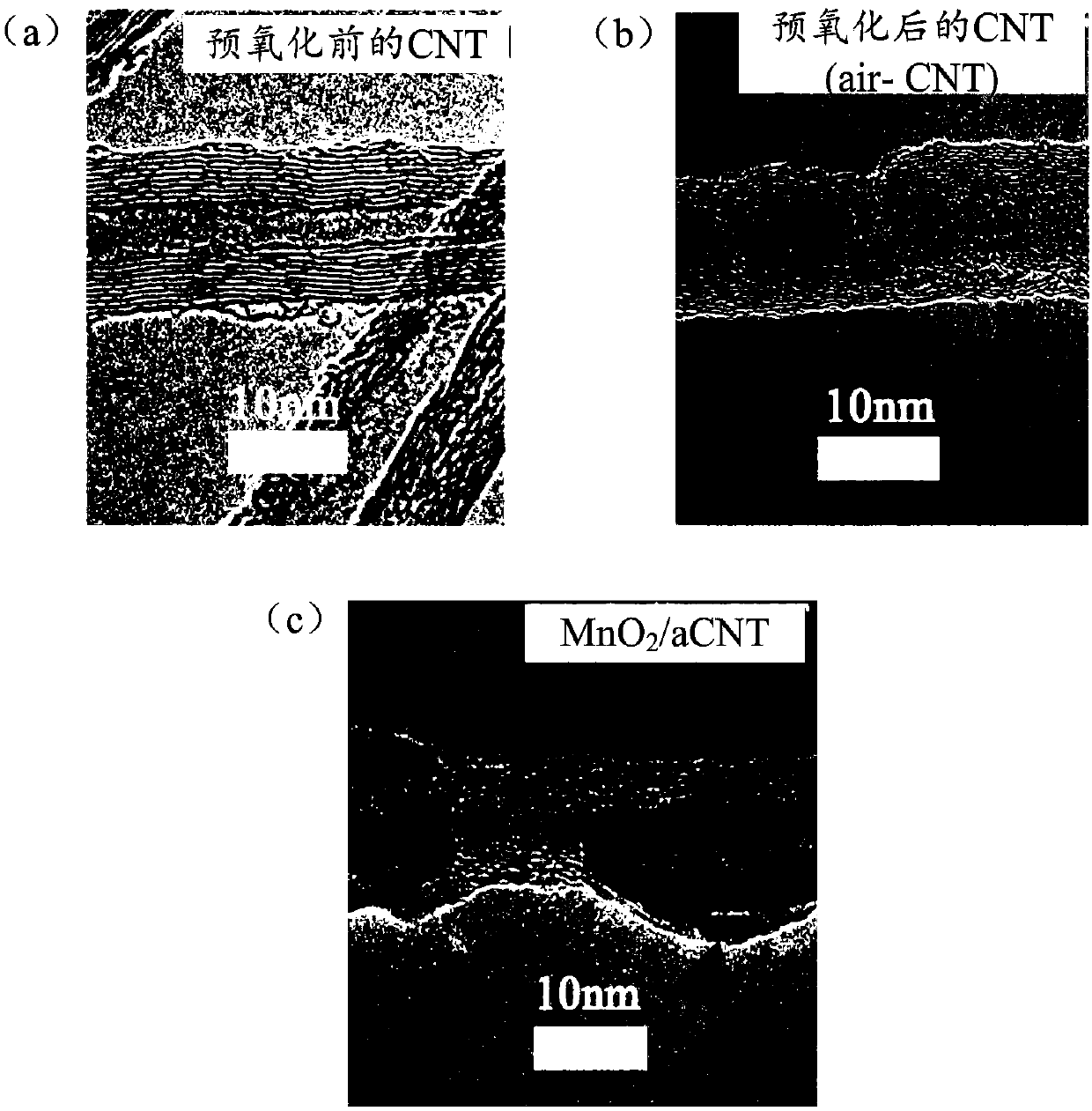

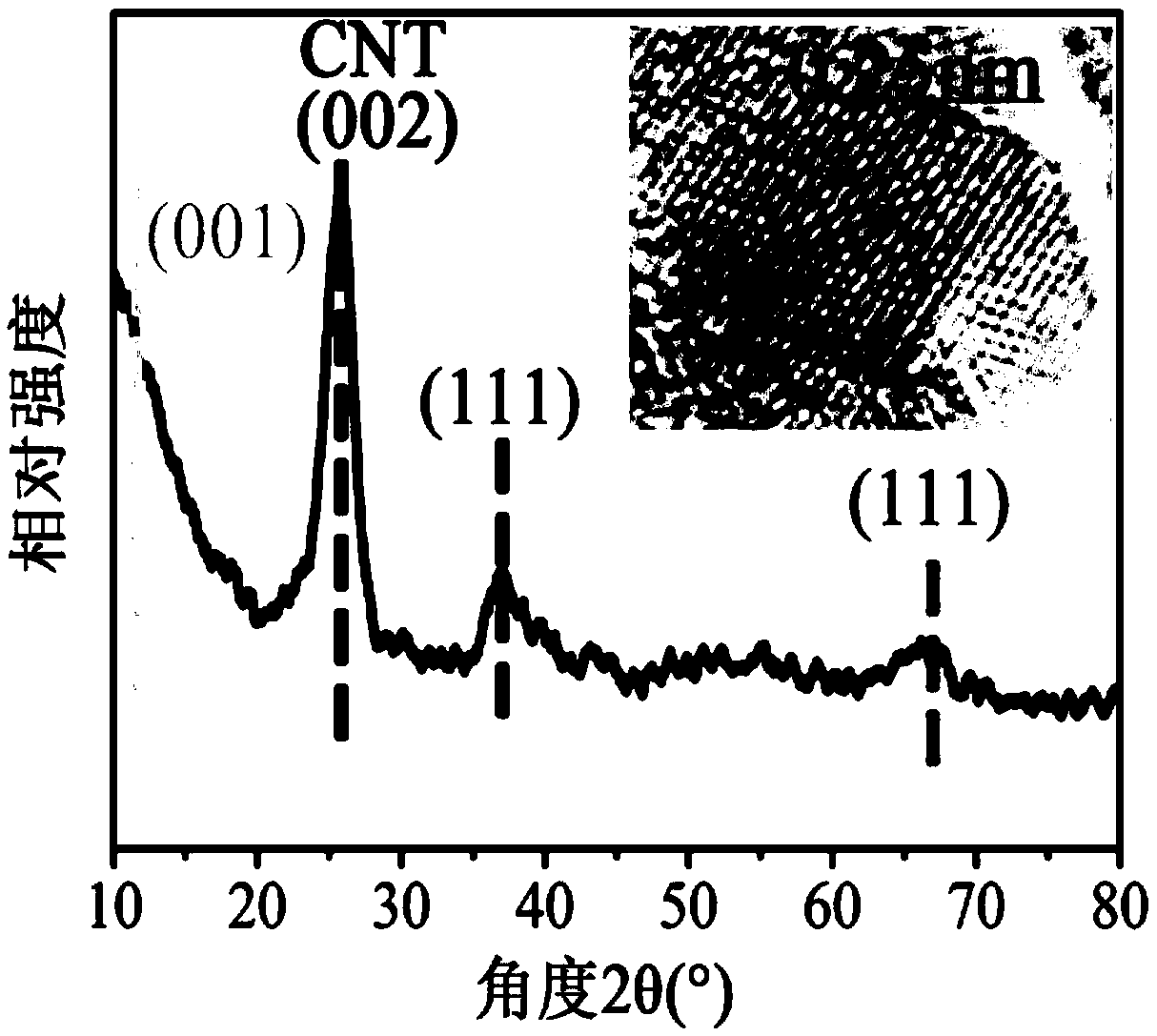

[0079] Preparation of MnO 2 / aCNT electrode: put a super-parallel array of carbon nanotubes in the air and heat at 550 degrees Celsius for 30 minutes to obtain air-CNT; then take 100 mg of air-CNT and disperse them in deionized water to obtain a suspension of carbon nanotubes Cloudy liquid, add 1.0 g of KMnO to the carbon nanotube suspension 4 , stirred magnetically at room temperature for 6 days, and then vacuum filtered to obtain a MnO 2 / aCNT composite film structure, the MnO 2 / aCNT composite film structure including multiple carbon nanotubes and MnO 2 Nanoparticle composition, MnO 2 Nanoparticles are combined with carbon nanotubes through C-O-Mn bonds, and the plurality of carbon nanotubes are intertwined to form a self-supporting film. Since the MnO 2 / aCNT composite film structure has good self-supporting and electrical conductivity, so the MnO 2 The / aCNT composite film structure can be used directly as a battery electrode without the need for current collectors ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com