4D-printing shape-memory-polymer-composite-material tracheal stent and preparing method thereof

A technology of memory polymers and tracheal stents, applied in stents, medical science, prostheses, etc., can solve problems such as blocked airway cilia swinging and difficult implantation of tracheal stents, so as to avoid the risk of tracheal stents, relieve pain, and relieve pain. small pain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1.4 Preparation method of tracheal stent made of D-printed shape-memory polymer composite material.

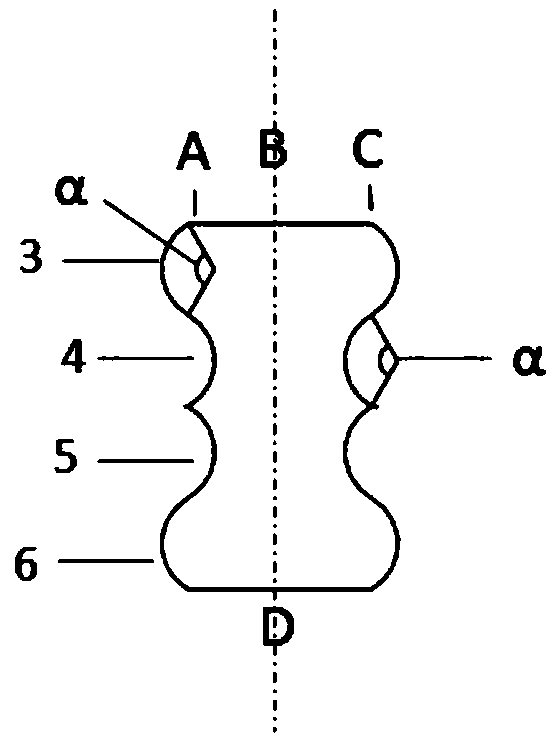

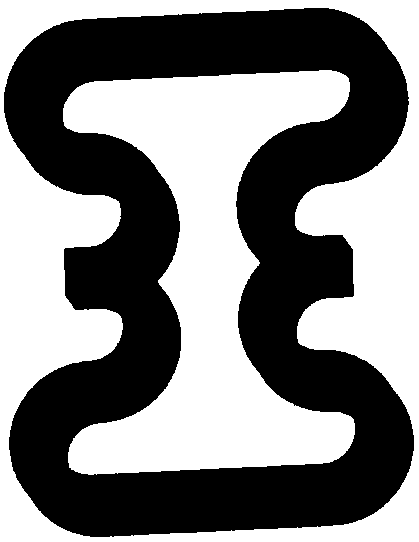

[0043] (1) Design the three-dimensional structure of the trachea support frame with a curved rectangle as the basic structural unit. The basic structure of the trachea support frame is mesh-shaped, the central angle corresponding to each arc is 60°, and the aperture of the support frame is 3×6mm. Wall thickness 1.5mm, diameter 10mm, see attached Figure 6 shown.

[0044] (2) Using fused deposition 3D printing technology to complete the molding and printing of the shape memory polymer composite material trachea support frame, the printing line is a standard printing line of polylactic acid composite material with a mass content of nano-ferric iron tetroxide powder of 10%, and the nano-4 The particle size of the iron oxide powder is 20nm; the printing speed is 40mm / s, the layer thickness is 0.2mm, the temperature of the extrusion head is 205°C, and the temperatur...

Embodiment 2

[0047] Example 2.4 The preparation method of tracheal stent made of D-printed shape memory polymer composite material.

[0048] (1) Design the three-dimensional structure of the tracheal support frame with the curved rectangle as the basic structural unit. The basic structure of the tracheal support frame is mesh-like, the central angle corresponding to the curved edge arc is 120°, and the aperture of the tracheal support frame is 5×10mm. Wall thickness 1.5mm, diameter 10mm, see attached Figure 9 shown.

[0049] (2) Using fused deposition 3D printing technology to complete the molding and printing of the shape memory polymer composite material trachea support frame, the printing line is a standard printing line of polylactic acid composite material with a mass content of nanometer ferroferric oxide powder of 15%, and the nanometer four The particle size of the iron oxide powder is 20nm; the printing speed is 40mm / s, the layer thickness is 0.2mm, the temperature of the extrus...

Embodiment 3

[0052] Example 3.4 The preparation method of tracheal stent made of 4D printed shape memory polymer composite material.

[0053] (1) Design the three-dimensional structure of the trachea support frame with the curved side rectangle as the basic structural unit. The basic structure of the trachea support frame is mesh-like, the central angle corresponding to the curved side arc is 180°, and the aperture of the trachea support frame is 5×10mm. Wall thickness 1.5mm, diameter 20mm.

[0054] (2) Using fused deposition 3D printing technology to complete the molding and printing of the shape memory polymer composite material tracheal support frame, the printing line is a standard printing line of polylactic acid composite material with a mass content of nanometer iron tetraoxide powder of 20%, and the nanometer four The particle size of the iron oxide powder is 20nm; the printing speed is 40mm / s, the layer thickness is 0.2mm, the temperature of the extrusion head is 205°C, and the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com