A 4D printing photosensitive resin based on dynamic covalent bond and its preparation method

A dynamic covalent bond and photosensitive resin technology, applied in the direction of additive processing, etc., can solve the problems of non-recyclable, low mechanical properties, environmental pollution, etc., achieve 100% atom utilization, excellent mechanical properties, simple and fast preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, the 4D printing photosensitive resin is a mixture of a reaction product of a dihydric mercaptan and a (meth)acrylate monomer containing an isocyanate group and a photoinitiator, specifically 3,6-dioxa-1,8-octyl Alkedithiol is a dibasic mercaptan, using isocyanoethyl methacrylate as a (meth)acrylate containing isocyanate groups, using N,N-diisopropylethylamine as a catalyst, and using phenyl bis( 2,4,6-Trimethylbenzoyl)phosphine oxide as photoinitiator.

[0039] In this embodiment, a method for preparing a 4D printing photosensitive resin based on a dynamic covalent bond, the specific steps are as follows:

[0040] Add 16g of 3,6-dioxa-1,8-octanedithiol and 0.04g of N,N-diisopropylethylamine to a flask equipped with a shading and stirring bar, mix well, and place on ice Slowly add 28 g of isocyanoethyl methacrylate into the water bath, and react at room temperature for 3 hours. After the reaction, add 0.4g of phenylbis(2,4,6-trimethylbenzoyl)phosphine ox...

Embodiment 2

[0042] In this example, the 4D printing photosensitive resin is a mixture of a reaction product of a dihydric mercaptan and a (meth)acrylate monomer containing an isocyanate group and a photoinitiator, specifically 3,6-dioxa-1,8-octyl Alkanedithiol is a dihydric mercaptan, with isocyanate ethyl acrylate as (meth)acrylate containing isocyanate groups, triethylamine as a catalyst, and phenyl bis(2,4,6-trimethylbenzyl Acyl)phosphine oxides are examples of photoinitiators.

[0043] In this embodiment, a method for preparing a 4D printing photosensitive resin based on a dynamic covalent bond, the specific steps are as follows:

[0044] Add 16g of 3,6-dioxa-1,8-octanedithiol and 0.04g of triethylamine into a darkened flask equipped with a stirring bar. After mixing evenly, slowly add 25g of isocyanate in an ice-water bath Ethyl acrylate, react at room temperature for 1 hour. After the reaction, 0.4g of 2,4,6-trimethylbenzoyldiphenylphosphine oxide was added, and stirred evenly to ...

Embodiment 3

[0046] In this example, the 4D printing photosensitive resin is a mixture of a reaction product of a dihydric thiol and a (meth)acrylate monomer containing an isocyanate group, and a photoinitiator, specifically, 1,6-hexanedithiol is used as the dihydric thiol , with isocyanoethyl methacrylate as (meth)acrylate containing isocyanate group, 1,8-diazabicycloundec-7-ene as catalyst, 1-hydroxy-cyclohexyl- Phenyl phenone is an example of a photoinitiator.

[0047] In this embodiment, a method for preparing a 4D printing photosensitive resin based on a dynamic covalent bond, the specific steps are as follows:

[0048] Add 16g of 1,6-hexanedithiol and 0.04g of 1,8-diazabicycloundec-7-ene into a light-shielded flask equipped with a stirring bar, mix well, and slowly Add 28 g of isocyanoethyl methacrylate and react at room temperature for 2 hours. After the reaction, add 0.4g of 1-hydroxy-cyclohexyl-phenyl ketone, stir evenly to obtain a remodelable and recyclable 4D printing photose...

PUM

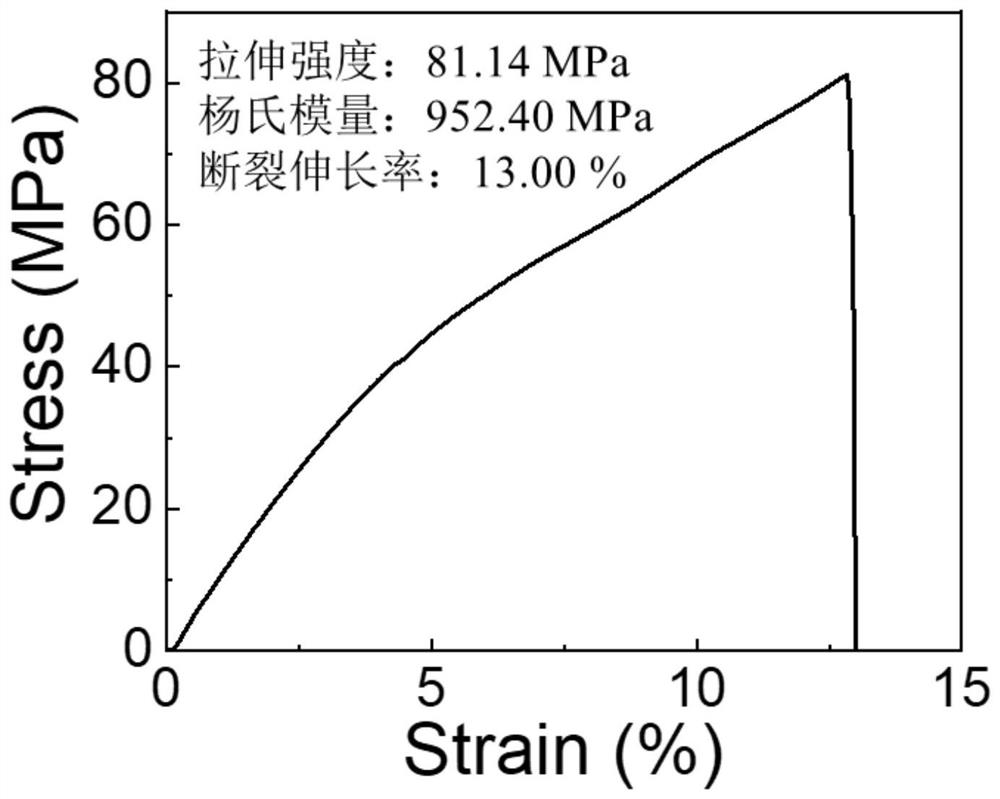

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com