A fine milling device for a mobile rail milling car

A mobile, driving device technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of insufficient surface finish of the rail, air and noise pollution, serious wear of the grinding wheel, etc., to achieve easy replacement, small environmental pollution, and easy operation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

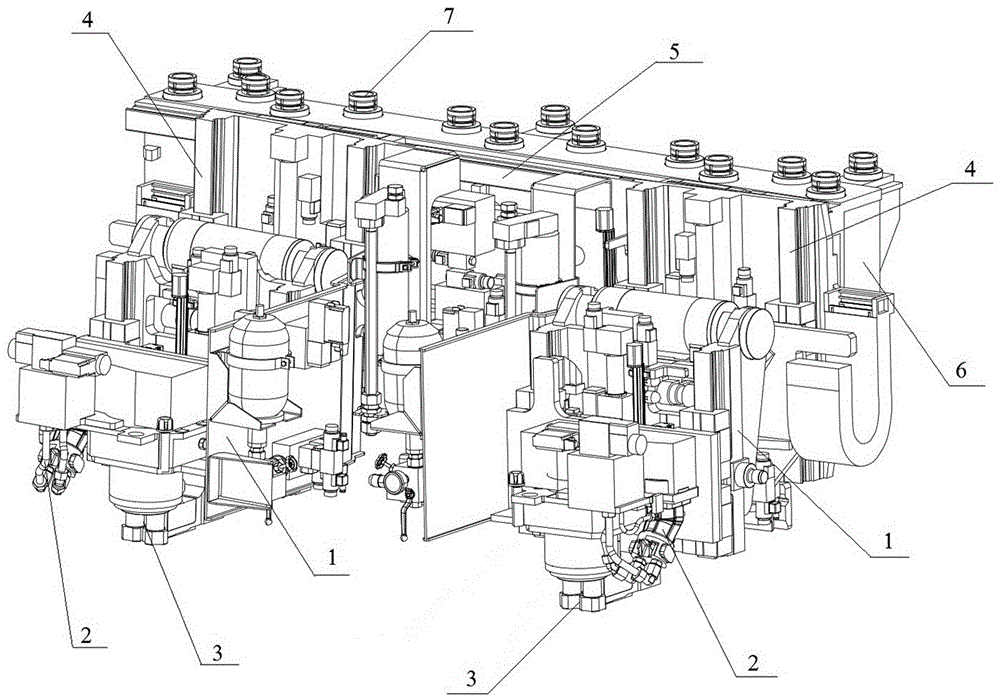

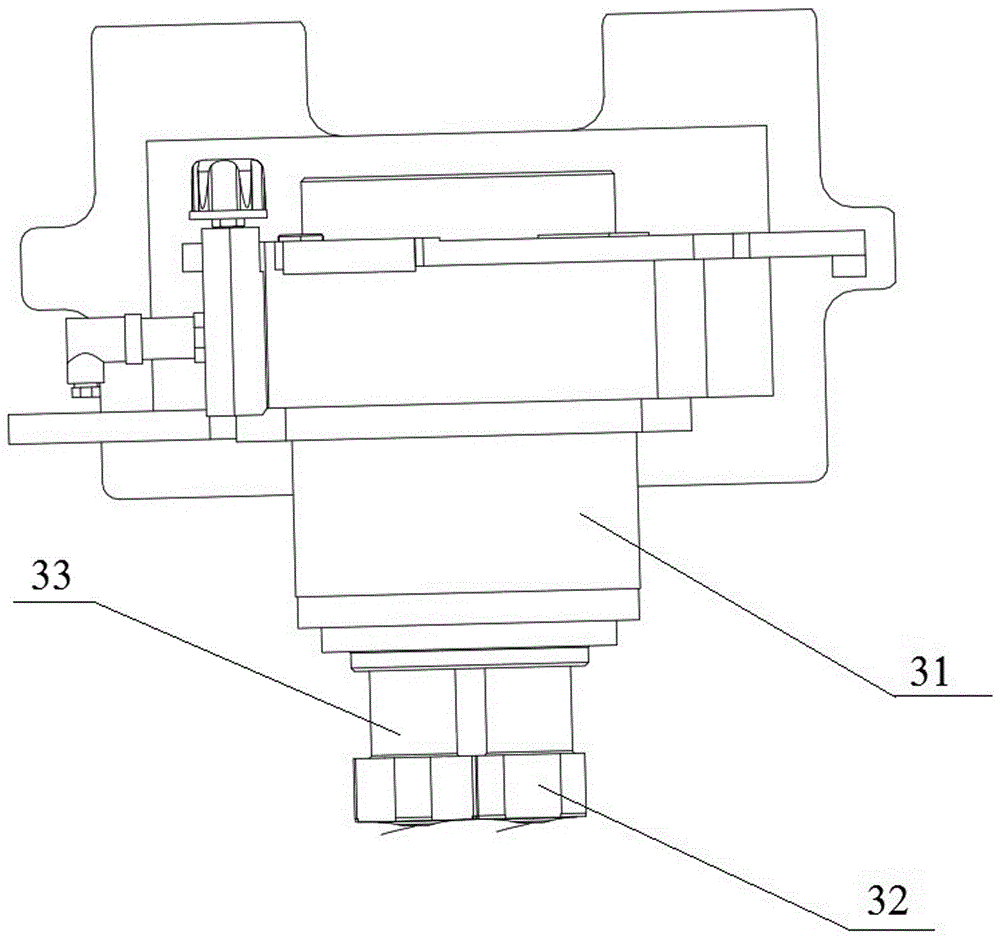

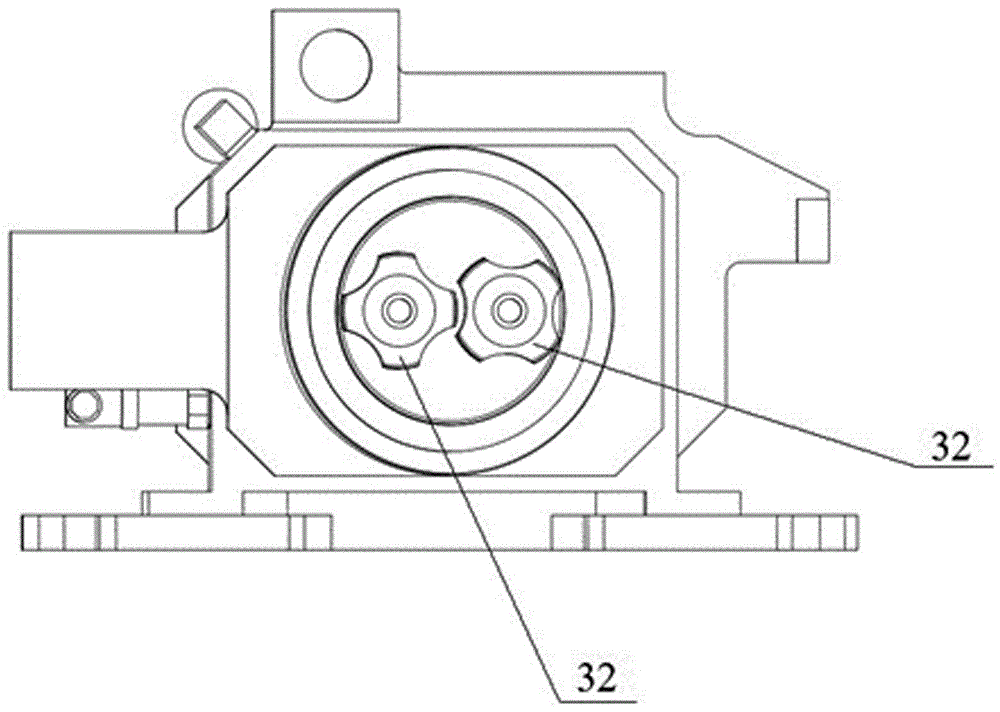

[0043] Embodiment 1.1, the fine milling device of the mobile rail milling car, which includes two tool holders 1, the tool holders 1 are arranged symmetrically about the transverse central axis of the connecting beam 6, the tool holder 1 is connected to the milling drive device 2, and the lower end of the tool holder 1 is also Equipped with a milling head 3, the output end of the milling driving device 2 is connected to the drive shaft of the milling head 3 through a mechanical transmission device, so as to drive the milling cutter on the milling head 3 and make it rotate perpendicular to the surface of the rail; the tool holder 1 is connected to the hydraulic storage The energy device is used to recover the fine milling device to the non-milling state when the hydraulic pipeline of the fine milling device leaks oil. One side of each tool holder 1 is also connected to a hydraulically driven vertical movement and positioning device 4 and a set of electric motors. Horizontal move...

Embodiment 12

[0054] Embodiment 1.2, the fine milling device of the mobile rail milling vehicle, is the same as Embodiment 1.1, except that two vertical guide rails are integrated with the second back plate.

Embodiment 13

[0055] Embodiment 1.3, the fine milling device of the mobile rail milling car, is the same as Embodiment 1.1, except that the horizontal guide rail 51 is integrated with the vertical surface of the connecting beam 6 .

[0056] The working mode of the fine milling device of the mobile rail milling car provided by the above embodiment is: during operation, the hydraulically driven vertical movement and the positioning device vertically move the fine milling device to attach the engaging rotary end milling tool holder to the surface of the rail, and the motorized horizontal The moving and positioning device controls the horizontal movement of the engaging rotary face milling tool holder until the fine milling device is in the working position, the milling drive device of the fine milling device is started, the cutter of the fine milling unit rotates at high speed, and the surface of the rail head is finished again. The surface of the rail is milled to eliminate the edges and corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com