Lens cone, lens module and electronic equipment

A technology of electronic equipment and lens modules, applied in the direction of installation, optics, instruments, etc., to achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

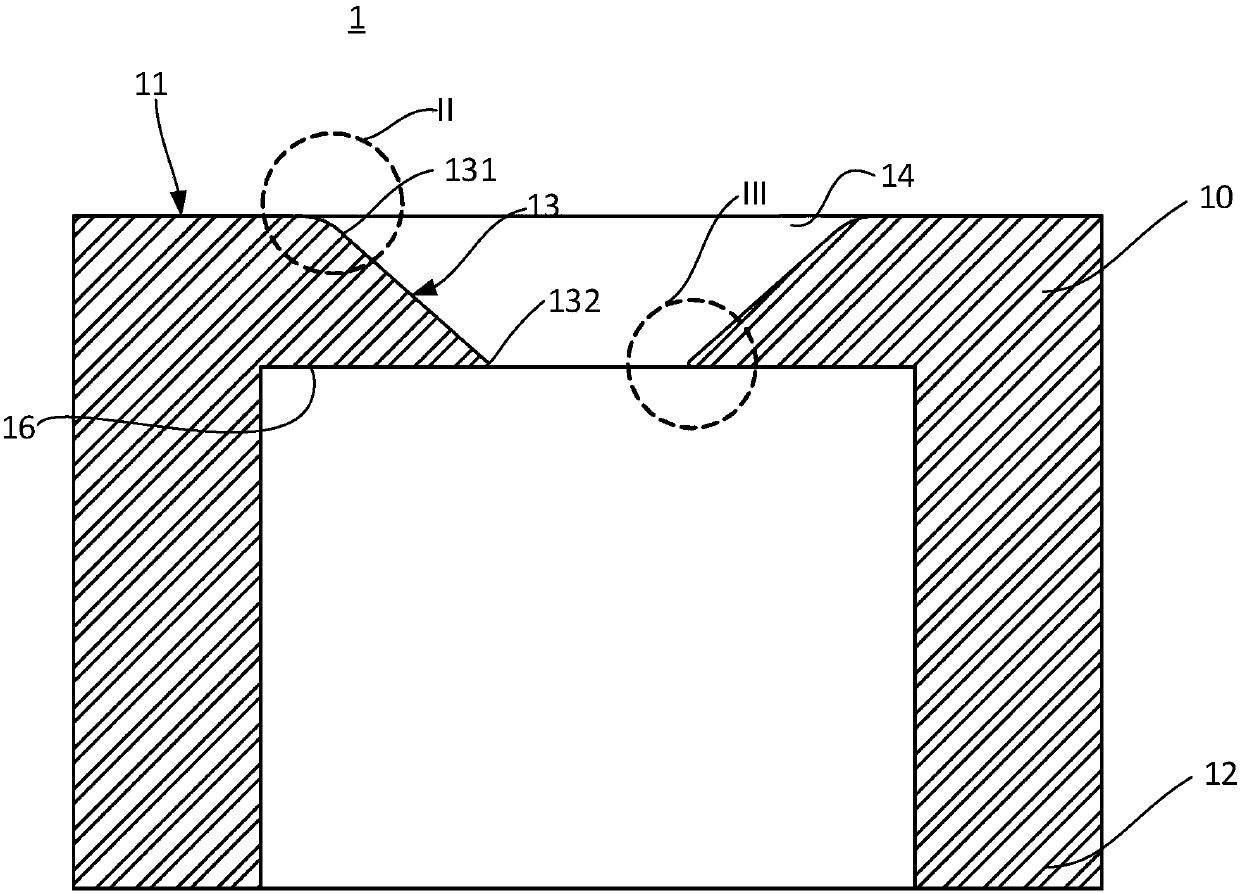

[0026] see Figure 1 to Figure 4 The lens barrel 1 provided in the first embodiment of the present application has a first end 10 and a second end 12 , and the first end 10 and the second end 12 are opposite ends of the lens barrel 1 .

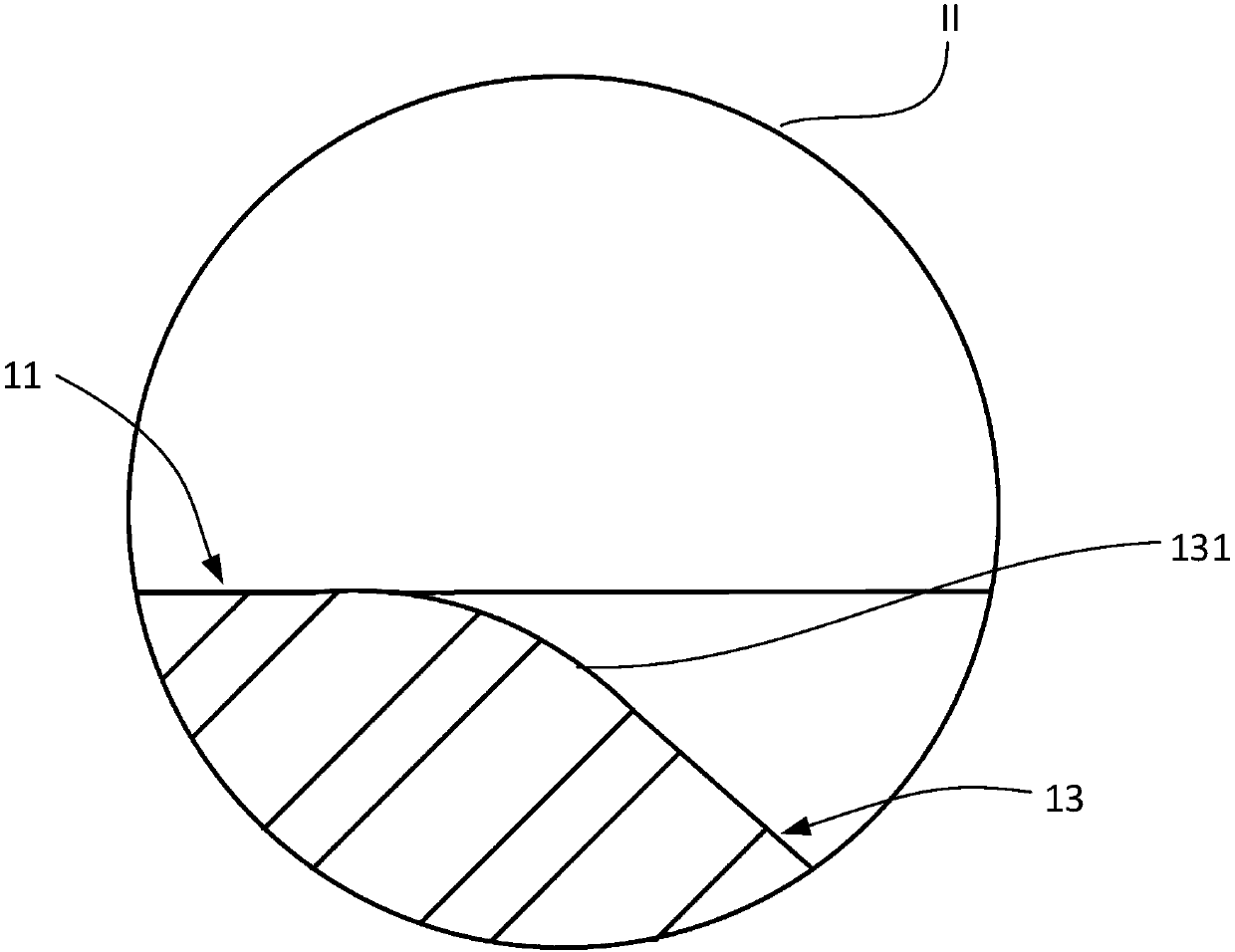

[0027] The first end portion 10 is provided with a light entrance hole 14 that communicates with the interior of the lens barrel 1. The first end portion 10 includes a first end surface 11 and an annular inner wall 13 connected to the first end surface 11. The annular inner wall 13 is arranged around the light entrance hole 14. . The light incident hole 14 is located at the center of the first end portion 10 .

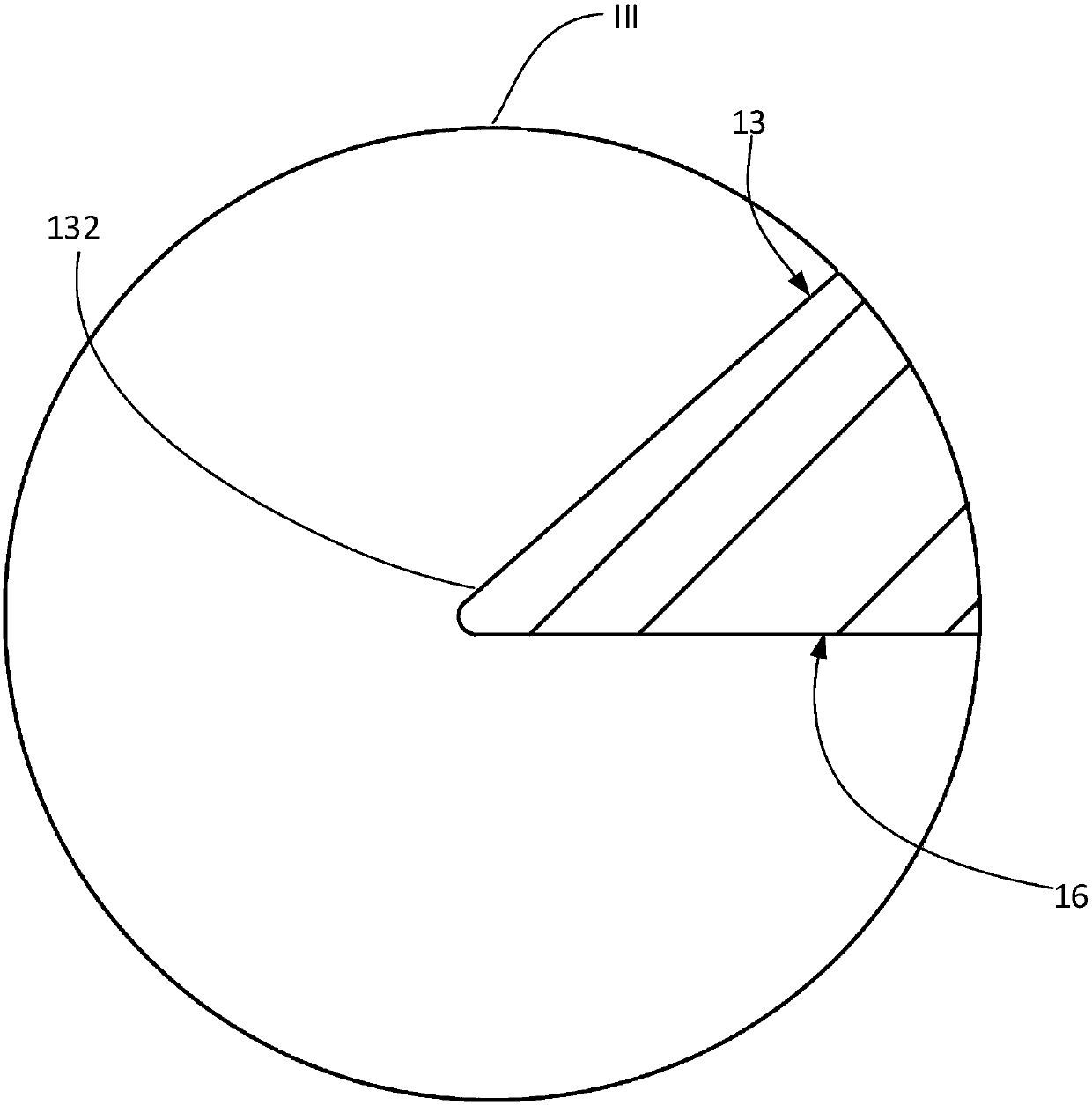

[0028] The annular inner wall 13 can be regarded as formed by the first end surface 11 entering inwardly into the interior of the lens barrel 1 . The annular inner wall 13 has a first peripheral edge 131 and a second peripheral edge 132 , and the height difference between the first end surface 11 and the second peripheral edge 132 is...

no. 2 example

[0034] see Figure 5 , in this embodiment, a lens module 2 is provided, the lens module 2 includes the lens barrel 1 provided in the first embodiment, and the lens group 20 , the lens group 20 is located inside the lens barrel 1 . Lens set 20 includes one or more lenses.

[0035] The lens barrel 1 of the lens module 2 has a circular arc transition around the light entrance hole without corners or ridges, which greatly improves the consistency of the structure.

no. 3 example

[0037] see Image 6 with Figure 7 This embodiment provides an electronic device 3 , the electronic device 3 has a first surface 31 and a second surface 32 opposite to the first surface 31 , and the first surface 31 is provided with a display screen 30 . The electronic device 3 includes the lens module 2 provided in the second embodiment. The lens module 2 is located on the first surface 31 and can be used as a front camera.

[0038] In one embodiment, the lens module 2 can also be located on the second surface 32 to be used as a rear camera.

[0039] In another embodiment, the electronic device 3 may have a first lens module and a second lens module, the two lens modules and the lens module 2 have the same structure, and are located on the first surface 31 and the second surface 32 respectively. .

[0040] In the electronic device 3 equipped with the lens module 2, the lens module eliminates the ridges around the light entrance hole, and the lines are smooth and harmonious...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com