Preparation method of metal-based shape memory composite

A composite material and metal-based technology, applied in metal rolling and other directions, can solve the problems of high equipment requirements, plate thickness particle loss, uneven dispersion, etc., and achieve simple preparation process, improved damping performance, and small particle loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a metal matrix shape memory composite material, comprising the steps of:

[0032] (1) First, put the NiTi metal powder in a beaker and vibrate in the ultrasonic vibrator for about 40 minutes. The purpose of using the ultrasonic vibrator to vibrate is to eliminate possible errors caused by the agglomeration of the NiTi metal powder and ensure the uniform dispersion of the NiTi metal powder.

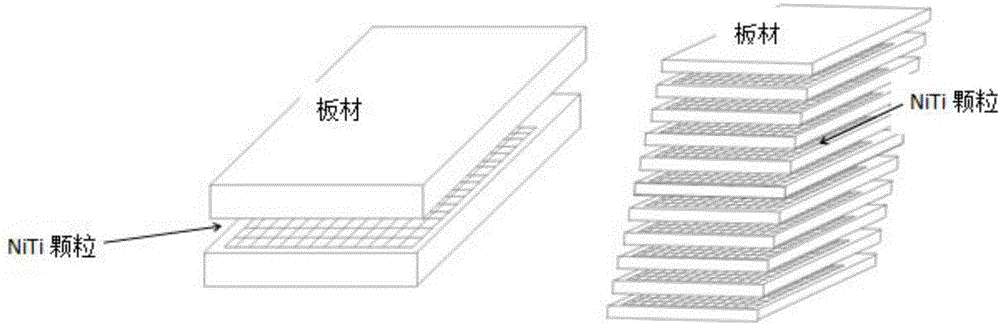

[0033] (2) Place the uniformly dispersed NiTi metal powder between two prefabricated metal plates (such as magnesium plates), add the NiTi metal powder in a tiled manner for rolling, and finish rolling in the first pass. Cut the rolled plate, continue to add NiTi metal powder to the two sheared plates, and then roll, repeating this step.

[0034] Among them, the thickness ratio of the metal plate is 1:1, and the same metal can be used for rolling, and different metals can also be selected for rolling. In addition to the above magnesium plates, the metal plate...

Embodiment 1

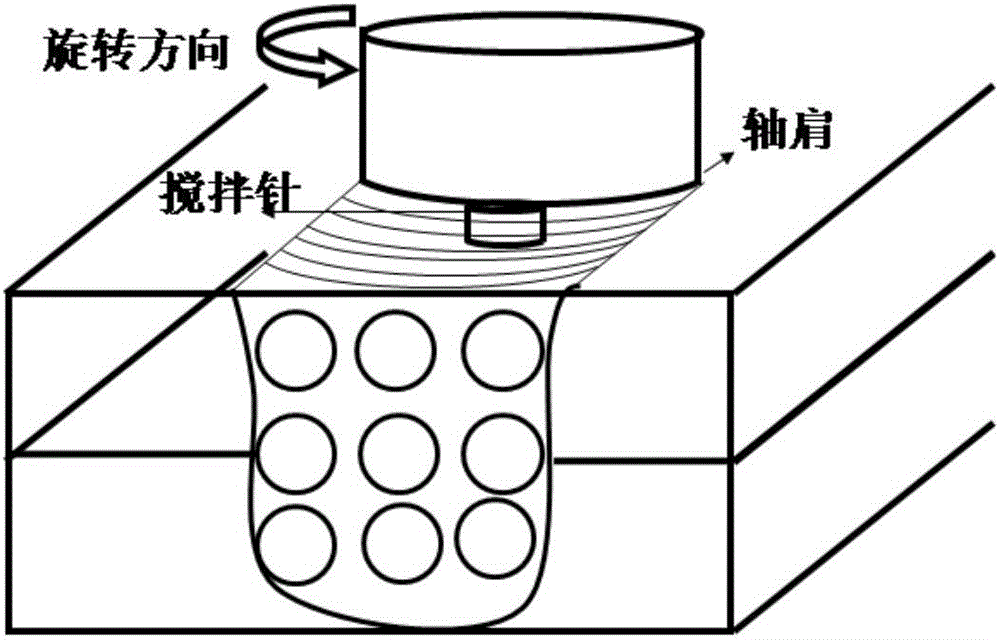

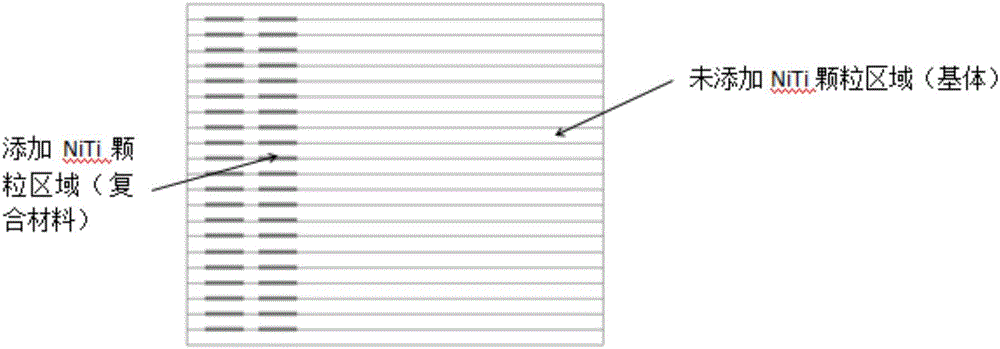

[0046] Large particle, integral NiTi particle reinforced same-material lamination welding manufacturing process: clean the overlapping surface of two AZ31 plates with a size of 80mm×80mm×2mm with ethanol and a steel brush, and add a diameter of 106 in the middle of the tile. ~150um NiTi particles, the number of particles added is about 1.36×10 3 ~1.91×10 3 piece / cm 2 , and fastened with rivets. Then heated at 350°C for 400s and taken out. Rolling is carried out on a Φ170×300 two-roll mill, the reduction rate is 50%, and the rolling speed is 0.4m / s. Cut from the middle after rolling. Repeat the above steps, take out after rolling for 5 passes, the final thickness of AZ31 plate is 4mm. Single-pass FSP processing was carried out under the condition of rotating speed of 750r / min and traveling speed of 118mm / min. The NiTi particles of the obtained composite material are basically lossless and very uniformly distributed, and are well combined with the matrix. No adverse inter...

Embodiment 2

[0048] Small particle, overall NiTi particle reinforced same-material lamination welding manufacturing process: clean the overlapped surface of two AZ31 plates with a size of 80mm×80mm×2mm with ethanol and a steel brush, and add a diameter of 2 -50um NiTi particles, the number of particles added is about 0.41×10 4 ~1.02×10 5 piece / cm 2 , and fastened with rivets. Then heated at 350°C for 400s and taken out. Rolling is carried out on a Φ170×300 two-roll mill with a reduction rate of 45% and a rolling speed of 0.4m / s. Cut from the middle after rolling. Repeat the above steps, take out after rolling for 6 passes, the final thickness of AZ31 plate is 2.1mm. Single-pass FSP processing was carried out under the condition of rotating speed of 750r / min and traveling speed of 118mm / min. The NiTi particles of the obtained composite material are basically lossless and very uniformly distributed, and are well combined with the matrix. No adverse interface reactions occurred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com