NxMy high-entropy alloy with shape memory effect and preparing method thereof

A high-entropy alloy and memory effect technology, applied in the field of NxMy high-entropy alloy with shape memory effect and its preparation, can solve the problems of difficult adjustment of phase transition temperature, hinder the development of low-temperature industry, and difficult to meet application requirements, etc., and reach the phase transition temperature wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Alloy composition

[0031] The alloy composition of embodiment 1 is TaNbTiNiCoFe

[0032] 2. Alloy melting

[0033] Alloy melting involves the following steps:

[0034] Step 1: Take 16.67% Ni, 16.67% Co, and 16.67% Fe and place them in a crucible in an electric arc furnace, then take 16.67% Ta, 16.66% Nb, and 16.66% Ti and place them on the surface of the previously placed elements to cover them. (Place elements with high melting points on the upper layer)

[0035] Step 2: Turn on the arc, first burn the upper element red with a small arc, and then adjust the current to melt the upper element and then fuse with the lower element.

[0036] Step 3: Place the alloy ingot in the crucible several times, and form an angle of 20°-40° with the horizontal plane, and repeat the melting 4 times to obtain the alloy ingot.

[0037] 3. Microstructure characteristics and shape memory properties of alloys

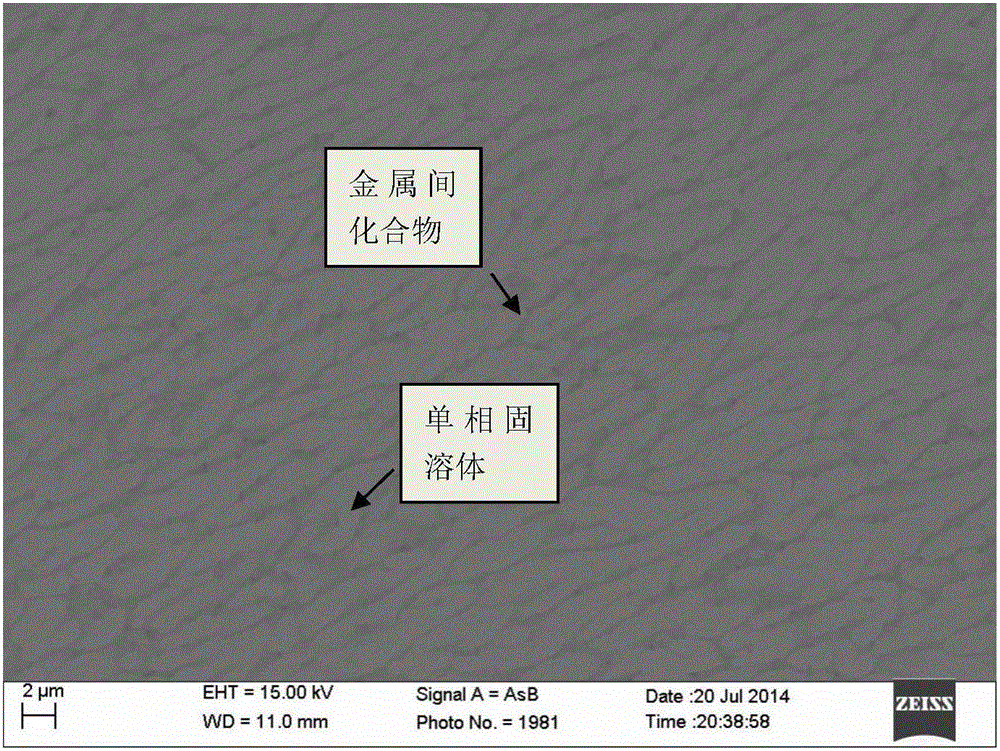

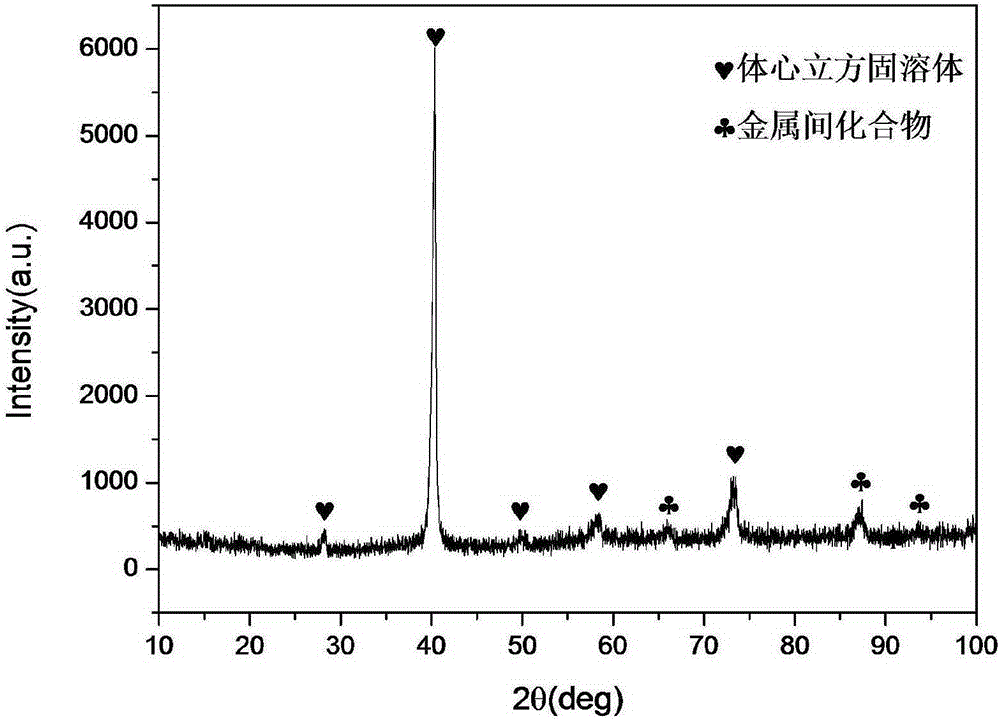

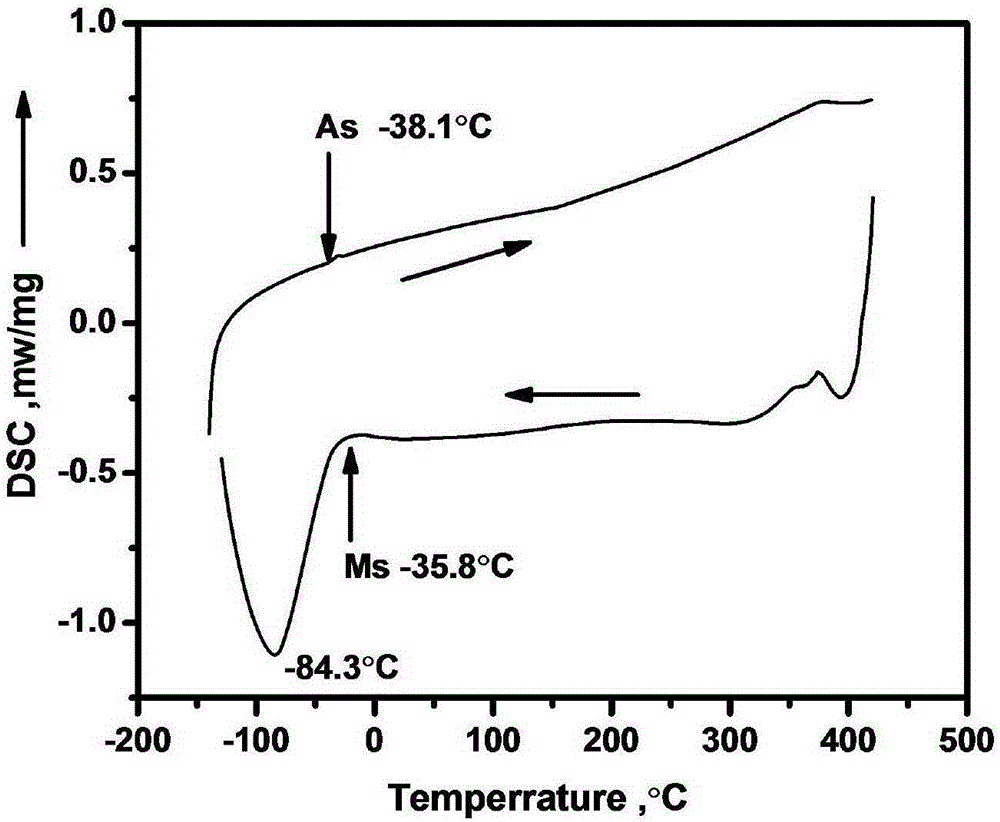

[0038] Depend on figure 1 and figure 2 It can be seen that the micro...

Embodiment 2

[0040] 1. Alloy composition

[0041] The alloy composition of Example 2 is TiZrFeNi.

[0042] 2. Alloy melting

[0043] Alloy melting involves the following steps:

[0044]Step 1: Take 25% Ni and 25% Fe and place them in a crucible in an electric arc furnace, and then take 25% Ti and 25% Zr and place them on the surface of the elements placed first to cover them. (Place elements with high melting points on the upper layer)

[0045] Step 2: Turn on the arc, first burn the upper element red with a small arc, and then adjust the current to melt the upper element and then fuse with the lower element.

[0046] Step 3: Place the alloy ingot in the crucible several times, and form an angle of 20°-40° with the horizontal plane, and repeat the melting 4 times to obtain the alloy ingot.

[0047] 3. Microstructure characteristics and shape memory properties of alloys

[0048] Figure 6 and Figure 7 These are the XRD and SEM topography images of the invented alloy example. It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com