Preparation method of poly(sebacoyl diglyceride) shape memory elastomer

A technology of sebacoyl diglyceride and sebacoyl, which is applied in the field of preparation of poly-shape memory elastomers, and can solve the problems of limited application, melting point drop, and inability to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

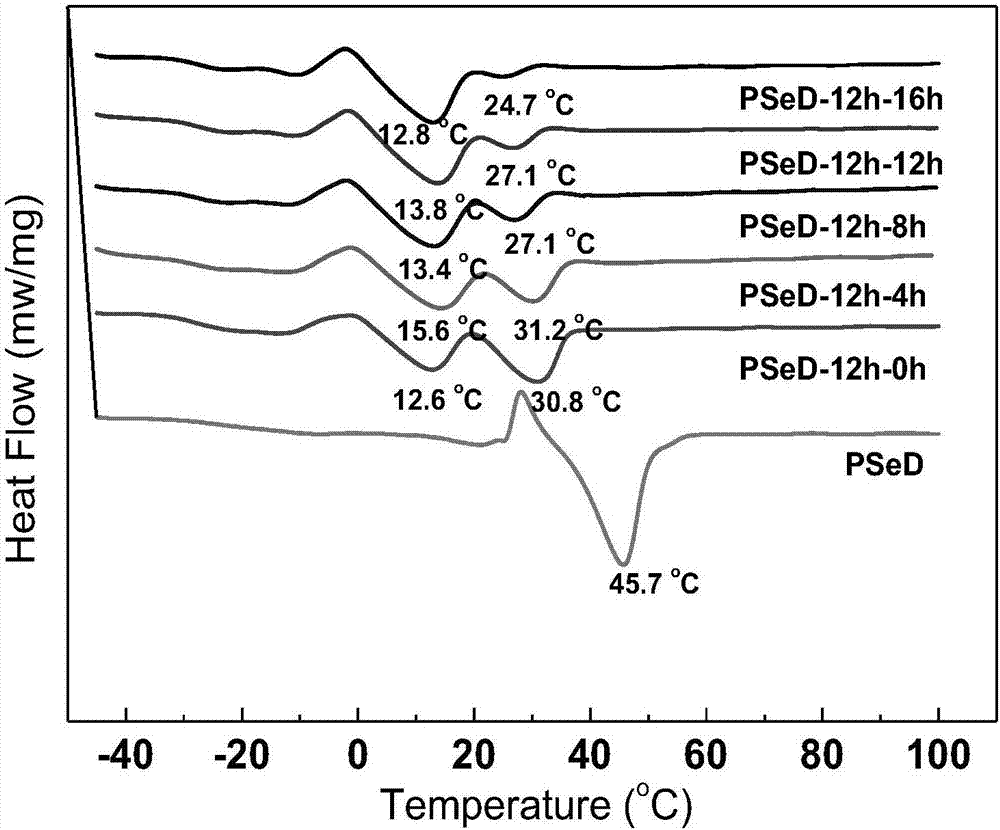

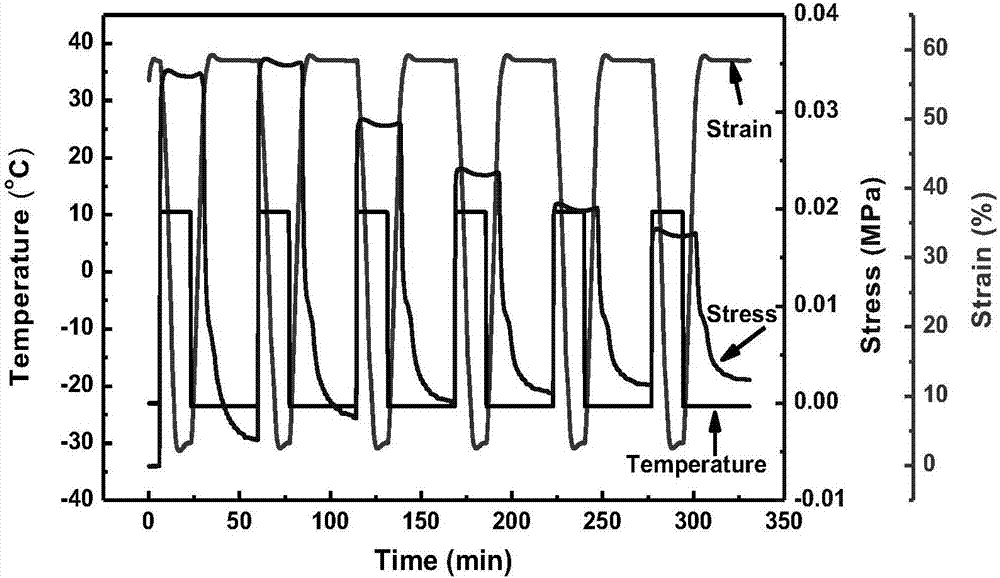

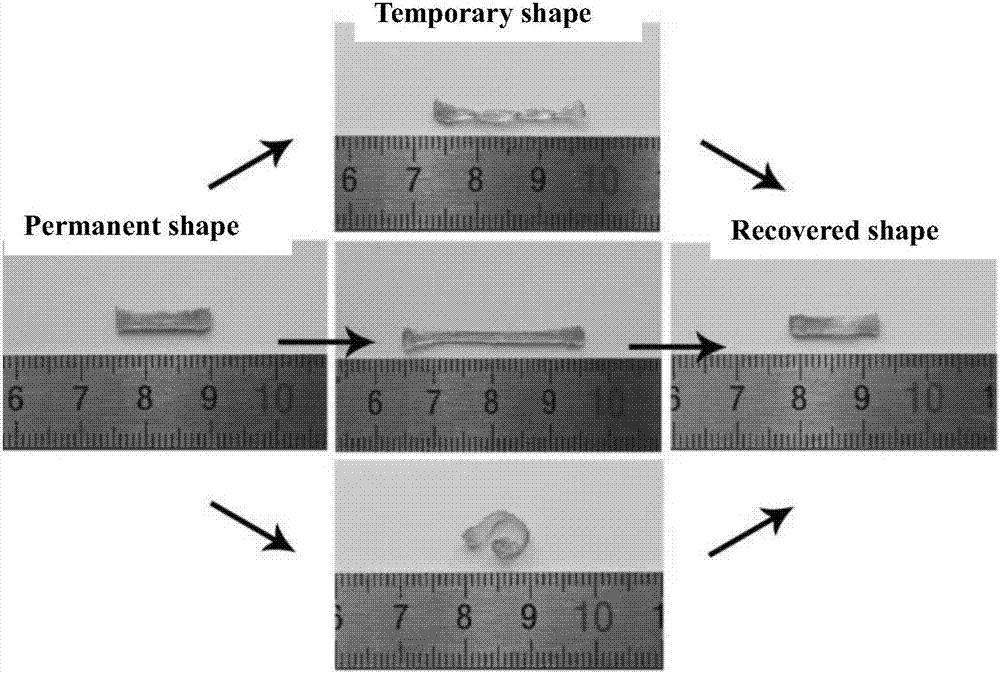

Method used

Image

Examples

Embodiment 1

[0025] (1) Purification of raw materials

[0026] Recrystallization of sebacic acid: Weigh 50g of sebacic acid to be purified, add it to a 500ml three-neck round bottom flask, add a rotor, connect the condensation reflux device, place the flask in an oil bath at 80°C, and gradually add ethanol Stir until the solution is clear and the sebacic acid is completely dissolved. Pour the solution in the flask into a beaker, cool at room temperature, let stand to allow the sebacic acid to crystallize, and then carry out suction filtration. After the above steps were repeated three times, the product was dried in a vacuum oven at 60° C. for 24 h.

[0027] (2) Synthesis of PSeD monomer sebacoyl glycidyl ester

[0028] Use sodium wire to remove water in toluene, and obtain anhydrous toluene after reflux for future use. The water in the triethylamine was removed with sodium hydroxide, and anhydrous triethylamine was obtained after reflux for subsequent use. A 500ml three-neck round-bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com