High-stability wood flame retardant

A flame retardant, wood technology, applied in the field of flame retardants, can solve the problems of affecting the mechanical properties of wood, poor flame retardant effect, etc., and achieve the effect of improving energy dispersion, tensile resistance, and preventing uneven dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

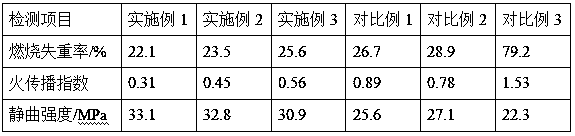

Examples

preparation example Construction

[0027] The preparation method of composite flame retardant component A, comprises the steps:

[0028] (1) Mix ferrous sulfate, sodium hypochlorite and water at 30~40°C according to the mass ratio of 7:1~3:25~35, and stir magnetically at 400~700r / min for 35~60min to obtain the mixture. Take the mixture Add titanium sulfate and sodium dihydrogen phosphate at a mass ratio of 8-12:1:1 and mix, heat up to 60-75°C, keep warm for 2-4 hours to obtain a matrix, take the matrix and add reagent A at a mass ratio of 15:1-4 Mix evenly to obtain an inorganic treatment product;

[0029] (2) According to the mass ratio of 4:1~3:15~25:0.1, take 2-vinyl-4,6-diamino-1,3,5-triazine, N,N-dimethylacrylamide, di Mix methyl sulfoxide and polyethylene glycol diacrylate in the reactor, stir magnetically at 500~800r / min for 30~60min, add TiO with 8~15% polyethylene glycol diacrylate mass 2 , 3-6 times the weight of polyethylene glycol diacrylate additives, 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiop...

Embodiment 1

[0036] Reagent A: Mix dicyandiamide, boric acid, and 70% phosphoric acid solution at a mass ratio of 3:1:20 at 85°C, and stir magnetically at 500 r / min for 35 minutes to obtain reagent A.

[0037] Reagent B: Mix xylene and diethylenetriamine at a volume ratio of 3:2 to obtain Reagent B.

[0038] Foaming agent: Mix petroleum ether and calcium bicarbonate at a mass ratio of 2:1 to obtain a foaming agent.

[0039] Dispersant: Mix dodecyldimethyl betaine and cetyltrimethylammonium bromide at a mass ratio of 5:2 to obtain a dispersant.

[0040] Cross-linking agent: at 2°C, mix polyethylene glycol, triethylamine, and methylene chloride in a reaction kettle at a mass ratio of 1:3:12, stir magnetically at 400r / min for 35min, and then add polyethylene glycol with a mass of 6 % acryloyl chloride was stirred evenly, and stood at room temperature for 20 hours, then filtered with suction, and the filtrate was mixed with diethyl ether at a mass ratio of 7:3, filtered with suction, and the ...

Embodiment 2

[0052] Reagent A: Mix dicyandiamide, boric acid, and 70% phosphoric acid solution at a mass ratio of 3:1:35 at 95°C, and stir magnetically at 800r / min for 60 minutes to obtain reagent A.

[0053] Reagent B: Mix xylene and diethylenetriamine at a volume ratio of 7:2 to obtain Reagent B.

[0054] Foaming agent: Mix petroleum ether and calcium bicarbonate at a mass ratio of 5:1 to obtain a foaming agent.

[0055] Dispersant: Mix dodecyldimethyl betaine and cetyltrimethylammonium bromide at a mass ratio of 8:2 to obtain a dispersant.

[0056] Cross-linking agent: at 5°C, mix polyethylene glycol, triethylamine, and methylene chloride in a reaction kettle at a mass ratio of 1:5:12, stir magnetically at 700r / min for 60min, and then add polyethylene glycol with a mass of 10 % acryloyl chloride was stirred evenly, left standing at room temperature for 24 hours, suction filtered, the filtrate was mixed with diethyl ether at a mass ratio of 12:3, suction filtered, and the filter residue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com