Preparation method based on liquid crystal elastomer and 4D printing and product

A technology of liquid crystal elastomers and liquid crystal monomers, applied in liquid crystal materials, chemical instruments and methods, processing and manufacturing, etc., can solve the problems of single deformation and limited use of liquid crystal elastomers, and achieve superior performance, strong applicability, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

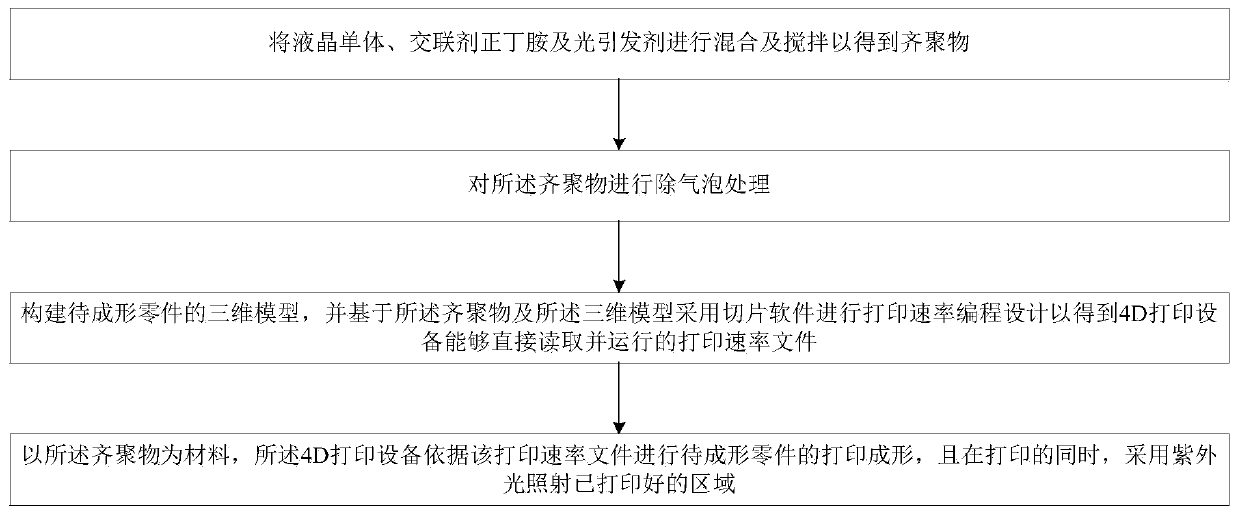

[0026] see figure 1 , the preparation method based on liquid crystal elastomer and 4D printing provided by the present invention, the preparation method mainly includes the following steps:

[0027] Step 1, mixing and stirring the liquid crystal monomer, the cross-linking agent n-butylamine and the photoinitiator to obtain an oligomer.

[0028] Specifically, after mixing the liquid crystal monomer and the crosslinking agent n-butylamine according to the molar ratio (1-1.5): 1, then add ( 1-2)% of the photoinitiator and then stirred at 80-110°C for 18h-24h to obtain oligomers.

[0029] In this embodiment, the liquid crystal monomer is liquid crystal monomer RM82, and the photoinitiator is Irgacure369; the oligomer is an opaque yellow viscoelastic material at room temperature.

[0030] In step 2, the oligomer is subjected to debubbling treatment to make the printing process smoother and to avoid quality defects of the printed product.

[0031] Specifically, the oligomer is lo...

Embodiment 1

[0039]The preparation method based on liquid crystal elastomer and 4D printing provided in Example 1 of the present invention mainly includes the following steps:

[0040] (1) Preparation of oligomer: Mix the liquid crystal monomer RM82 and the crosslinking agent n-butylamine in a round-bottomed flask at a molar ratio of 1:1, and add a mass equal to the liquid crystal to the round-bottomed flask. 1.5% photoinitiator Irgacure369 based on the mass sum of the monomer RM82 and the cross-linking agent n-butylamine was stirred in an oil bath at 110° C. for 18 hours to obtain an oligomer.

[0041] (2) Remove air bubbles: put the oligomer into the barrel of the 4D printing equipment, then put the barrel into a vacuum oven at a temperature of 80°C and a vacuum of 5×10 3 The drying time under Pa is 12h.

[0042] (3) Geometric modeling and printing rate programming design: use 3D modeling software to build a 3D model of the file to be formed and export the STL file, and use slicing soft...

Embodiment 2

[0045] The preparation method based on liquid crystal elastomer and 4D printing provided in Example 2 of the present invention mainly includes the following steps:

[0046] (1) Preparation of oligomer: Mix the liquid crystal monomer RM82 and the crosslinking agent n-butylamine in a round-bottomed flask with a molar ratio of 1.3:1, and add a mass of the liquid crystal to the round-bottomed flask. 2% photoinitiator Irgacure369 based on the mass sum of the monomer RM82 and the cross-linking agent n-butylamine was stirred in an oil bath at 80° C. for 22 hours to obtain an oligomer.

[0047] (2) Remove air bubbles: put the oligomer into the barrel of the 4D printing equipment, then put the barrel into a vacuum oven at a temperature of 100°C and a vacuum of 2×10 3 The drying time under Pa is 9h.

[0048] (3) Geometric modeling and printing rate programming design: use 3D modeling software to build a 3D model of the file to be formed and export the STL file, and use slicing software...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com