Drug releasing method based on 4D printing shape memory polymer structure

A memory polymer and drug release technology, which is applied in the direction of making drugs into special physical or taking forms of devices, additive processing, etc., can solve the problems of low repeatability, high production cost, complex pharmaceutical process, etc. Strong repeatability, low preparation cost, overcoming the effect of complex pharmaceutical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

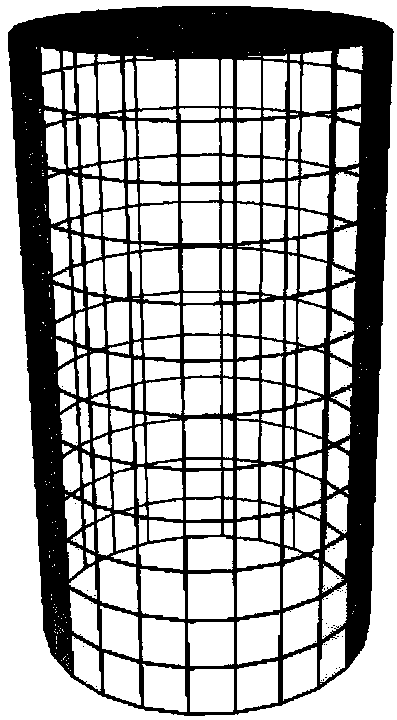

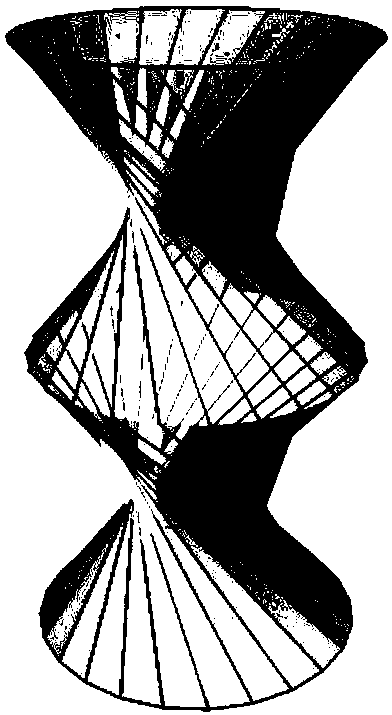

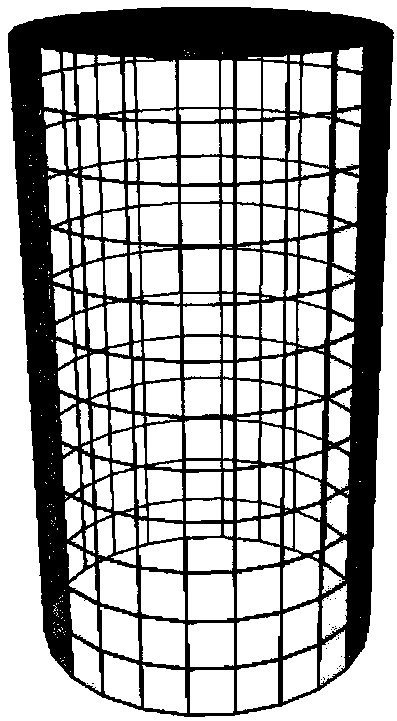

[0025] Specific Embodiment 1: In this embodiment, a drug release method based on a 4D printed shape memory polymer structure is as follows: 1. Mix the shape memory polymer with the drug at room temperature to obtain a drug-loaded shape memory polymer; 2. The drug-loaded shape memory polymer is prepared by 4D printing technology to prepare the drug release structure of the initial configuration; 3. Heating the drug release structure of the initial configuration to the glass transition temperature, and then changing the drug release structure of the initial configuration into a temporary The drug release structure of the configuration, and then down to room temperature, the drug release structure of the temporary configuration is obtained; wherein the surface area of the drug release structure of the temporary configuration is smaller than the drug release structure of the initial configuration; four, release the drug release structure of the temporary configuration In an envir...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass percentage of the drug in the drug-loaded shape memory polymer in Step 1 is 0.5-15%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the shape memory polymer is polylactic acid, polyvinyl alcohol, polyurethane, polycaprolactone, chitosan, cross-linked polyethylene, One or more of polynorbornene, trans polyisoprene or styrene-butadiene copolymer are combined in any ratio. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com