Processing method suitable for 4D printed nickel-titanium shape memory alloy

A technology of memory alloy and processing method, which is applied in the field of alloy forming and manufacturing, can solve the problems such as shape memory effect and superelasticity of 4D printing nickel-titanium shape memory alloy, and achieve the elimination of structural defects, grain refinement, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

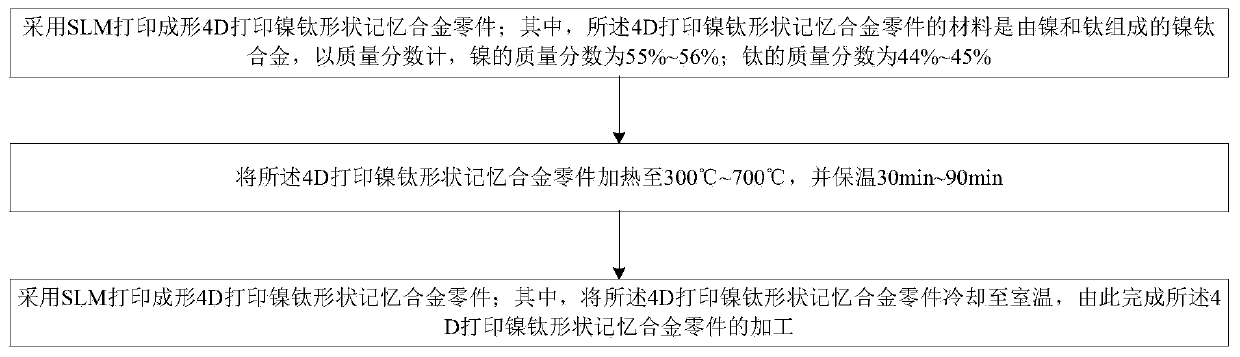

[0040] The processing method suitable for 4D printing nickel-titanium shape memory alloy provided by the first embodiment of the present invention mainly includes the following steps: put the 4D printing nickel-titanium shape memory alloy part into a high-temperature box furnace, and pass argon gas into the furnace ; Then raise the temperature of the high-temperature box furnace to 300°C at a heating rate of 80°C / h, keep it warm for 30 minutes and then cool it down to room temperature in the furnace.

Embodiment 2

[0042] The processing method suitable for 4D printing nickel-titanium shape memory alloy provided by the second embodiment of the present invention mainly includes the following steps: put the 4D printing nickel-titanium shape memory alloy part into a high-temperature box furnace, and pass argon gas into the furnace ; Then raise the temperature of the high-temperature box furnace to 300°C with a heating rate of 80°C / h, keep it warm for 60 minutes and then cool it to room temperature in the furnace.

Embodiment 3

[0044] The processing method suitable for 4D printing nickel-titanium shape memory alloy provided by the third embodiment of the present invention mainly includes the following steps: put the 4D printing nickel-titanium shape memory alloy part into a high-temperature box furnace, and pass argon gas into the furnace ; Then raise the temperature of the high-temperature box-type furnace to 300°C, the heating rate is 80°C / h, keep the temperature for 90 minutes, and then cool to room temperature in the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com