4D forming method for nickel-titanium alloy member with deformation recovery rapid response and product

A nickel-titanium alloy, fast-response technology, applied in the direction of additive manufacturing, additive processing, etc., can solve the problems affecting the shape memory effect and superelasticity of formed parts, the change of phase transition temperature and phase transition interval, and the lack of versatility of nickel-titanium alloy and other problems, to avoid large phase transition temperature changes, increase the surface area, and avoid uncontrollable changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

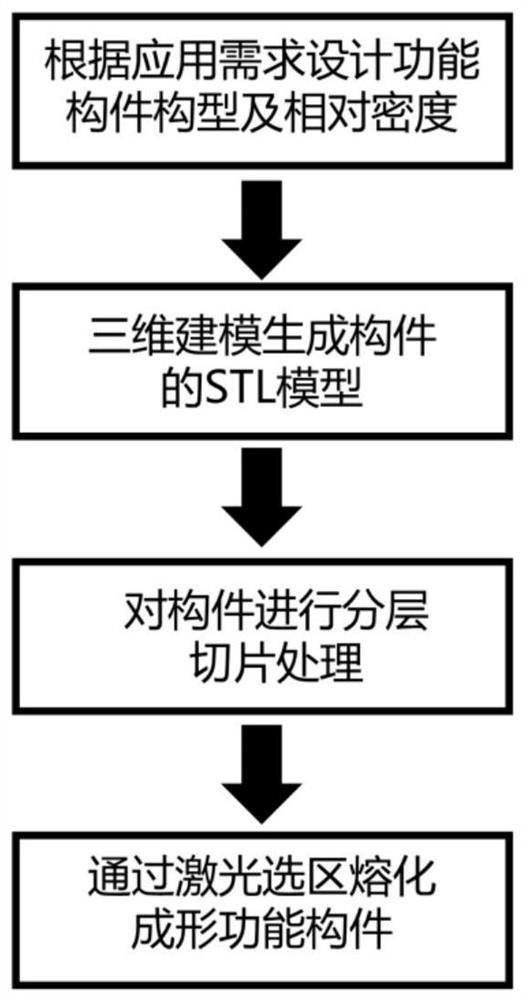

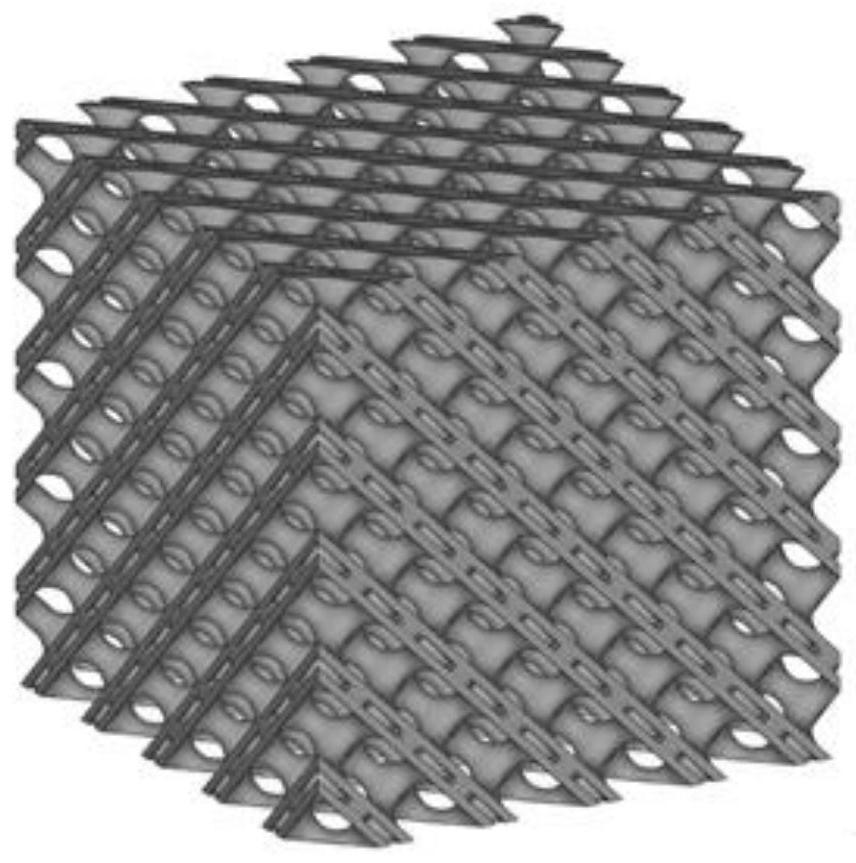

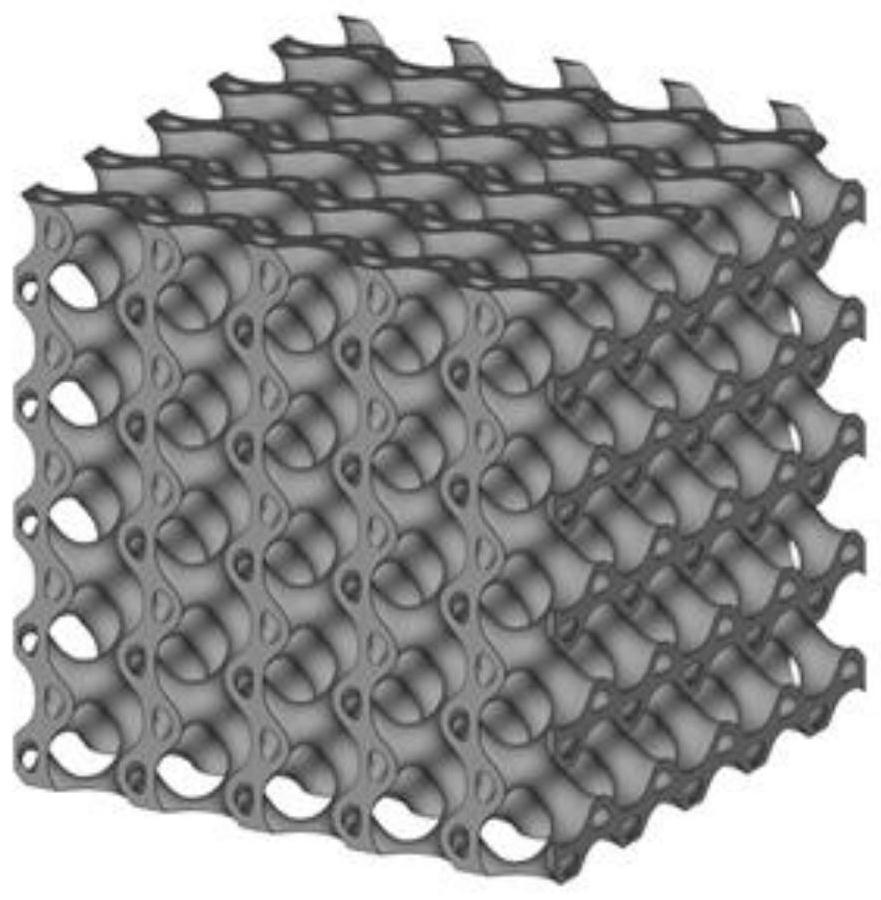

[0042] (1) According to the support strength and response speed of deformation recovery required by the 4D printed nickel-titanium alloy fast-response functional components in the application of metal bone implants, the unit cell configuration of the three-period minimal curved surface and the corresponding Relative density, the unit cell configuration used in this example is Gyroid structure, which spirals periodically in three directions, has good support strength, and the super large specific surface area is also more conducive to the recovery of deformation. This structure is also passed through The array method forms two lattice structures S with different relative densities A and the lattice structure S B , the lattice structure is designed as a cube with a side length of 20 mm, and the lattice structure S A The relative density is 10%, the lattice structure S B The relative density is 5%.

[0043] (2) Boolean operations are performed on two lattice structures with di...

Embodiment 2

[0047] (1) According to the support strength and response speed of deformation recovery required by the 4D printed nickel-titanium alloy fast-response functional components in the application of metal bone implants, the unit cell configuration of the three-period minimal curved surface and the corresponding Relative density, the unit cell configuration used in this example is Gyroid structure, which spirals periodically in three directions, has good support strength, and the super large specific surface area is also more conducive to the recovery of deformation. This structure is also passed through The array method forms two lattice structures S with different relative densities A and the lattice structure S B , the lattice structure is designed as a cube with a side length of 20 mm, and the lattice structure S A The relative density is 10%, the lattice structure S B The relative density is 5%.

[0048] (2) Boolean operations are performed on two lattice structures with di...

Embodiment 3

[0052] (1) According to the support strength and response speed of deformation recovery required by the 4D printed nickel-titanium alloy fast-response functional components in the application of metal bone implants, the unit cell configuration of the three-period minimal curved surface and the corresponding Relative density, the unit cell configuration used in this example is Gyroid structure, which spirals periodically in three directions, has good support strength, and the super large specific surface area is also more conducive to the recovery of deformation. This structure is also passed through The array method forms two lattice structures S with different relative densities A and the lattice structure S B , the lattice structure is designed as a cube with a side length of 20 mm, and the lattice structure S A The relative density is 50%, the lattice structure S B The relative density is 40%.

[0053] (2) Boolean operations are performed on two lattice structures with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com