Modular self-snow-melting pavement based on graphene

A self-melting snow pavement, graphene technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of poor fatigue resistance, discontinuous conduction, low conductivity, etc., to achieve extended service performance and durability, excellent toughness and Excellent crack resistance and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

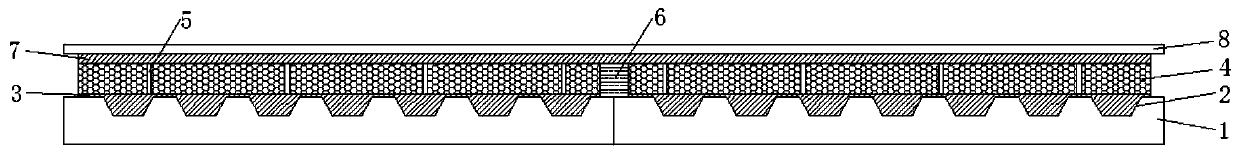

[0022] Specific embodiments: the self-melting snow pavement of modular multi-phase materials in this embodiment, the self-snow-melting pavement of modular multi-phase materials is spliced by a plurality of modular self-snow-melting pavement units, and the modular self-snow-melting pavement unit It includes a substrate 1, a lower asphalt layer 3, a graphene conductive asphalt layer 4, an electrode 5, an insulating asphalt layer 7 and a surface layer 8. The material of the substrate 1 is poor concrete, and the substrate 1 is provided with continuous horizontal or vertical Groove 2, the lower asphalt layer 3 is poured in the groove 2 and bonded by an emulsified asphalt adhesive. The graphene conductive asphalt layer 4 is arranged on the surface of the lower asphalt layer 3 and bonded by an emulsified asphalt adhesive. A plurality of electrodes 5 are arranged at intervals in the asphalt layer 4, the electrodes 5 are arranged along the thickness direction of the graphene conductiv...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: the thickness of the graphene conductive asphalt layer 4 is 3-5 cm, and the thickness of the insulating asphalt layer 7 is 0.3-1.0 cm. Others are the same as in the first embodiment.

specific Embodiment approach 3

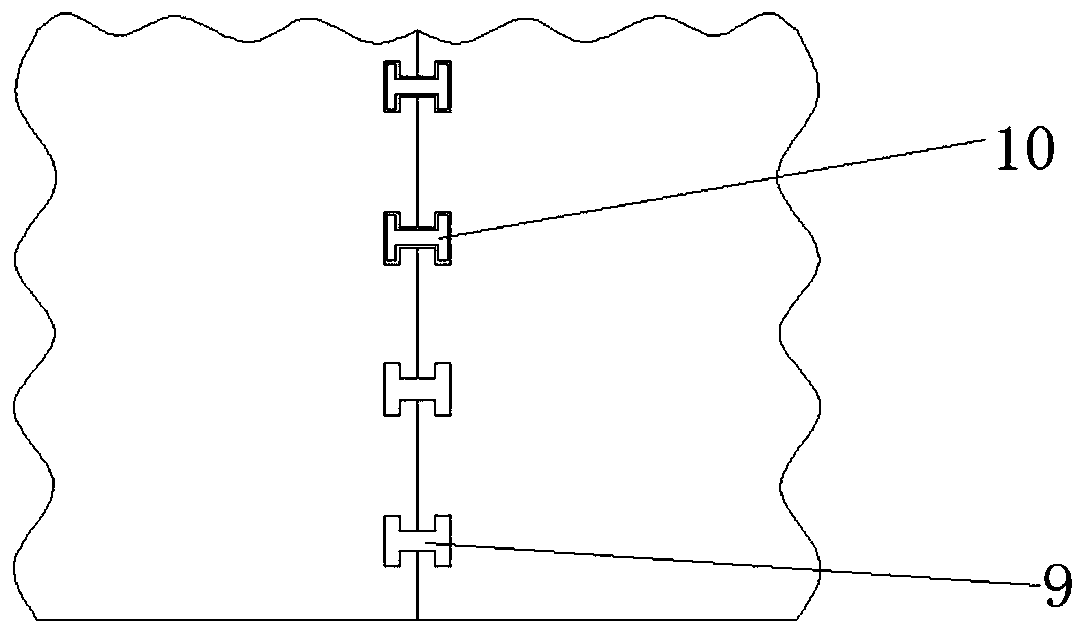

[0027] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that a plurality of tenon grooves 9 are formed on the side of the substrate 1 along the thickness direction of the substrate 1, and adjacent substrates 1 are spliced to form "H" shaped tenon grooves 9 , the mortise joint 10 is "H" shaped, and the tenon joint 10 is inserted into the tenon groove 9 . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com