Crack-free 4D printing titanium-nickel shape memory alloy and preparation method thereof

A memory alloy, crack-free technology, applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of memory alloy cracks, affecting mechanical properties, limiting the application of 4D printing titanium-nickel shape memory alloys, etc., to achieve yield Increased strength, good mechanical properties, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

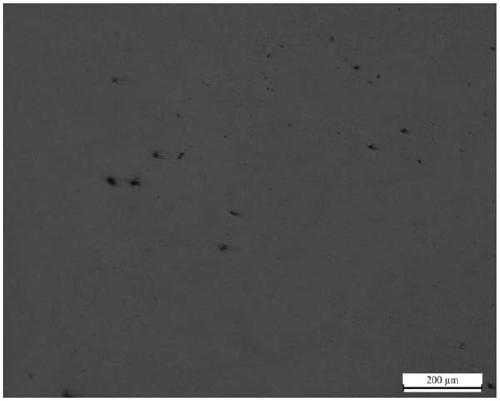

Embodiment 1

[0028] The crack-free 4D printed titanium-nickel shape memory alloy has the following weight percentages of its components: Ni: 55%, Ti: 42%, Zr: 3%.

[0029] A method for preparing a crack-free 4D printing titanium-nickel shape memory alloy, comprising the steps of:

[0030] Proportion the metal raw materials according to the setting, and after fully and uniformly melting, use the gas atomization method to obtain 4D printing titanium-nickel shape memory alloy powder, and then sieve the powder after drying to obtain the powder with the required particle size;

[0031] Adjust the SLM equipment, and pour the 4D printed titanium-nickel shape memory alloy powder into the powder feeding cylinder or the powder hopper. The scanning range is controlled within the geometric range of the substrate;

[0032] Laser processing and forming, that is, the SLM control system first uses the laser to repeatedly scan the substrate and preheat, and then spread powder and perform SLM printing and ...

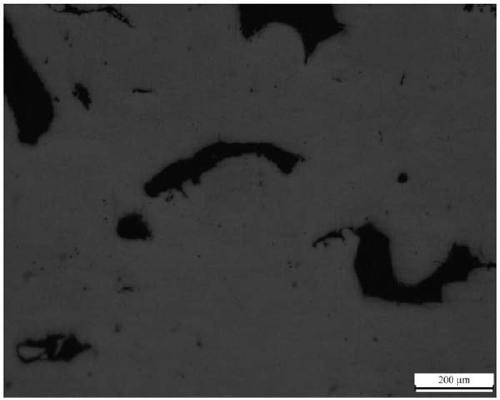

Embodiment 2

[0035] The crack-free 4D printed titanium-nickel shape memory alloy has the following weight percentages of its components: Ni: 55%, Ti: 42%, Zr: 3%.

[0036] A method for preparing a crack-free 4D printing titanium-nickel shape memory alloy, comprising the steps of:

[0037] Proportion the metal raw materials according to the setting, and after fully and uniformly melting, use the gas atomization method to obtain 4D printing titanium-nickel shape memory alloy powder, and then sieve the powder after drying to obtain the powder with the required particle size;

[0038] Adjust the SLM equipment, and pour the 4D printed titanium-nickel shape memory alloy powder into the powder feeding cylinder or the powder hopper. The scanning range is controlled within the geometric range of the substrate;

[0039] Laser processing and forming, that is, the SLM control system first uses the laser to repeatedly scan the substrate and preheat, and then spread powder and perform SLM printing and ...

Embodiment 3

[0042] The crack-free 4D printed titanium-nickel shape memory alloy has the following weight percentages of its components: Ni: 55%, Ti: 42%, Zr: 3%.

[0043] A method for preparing a crack-free 4D printing titanium-nickel shape memory alloy, comprising the steps of:

[0044] Proportion the metal raw materials according to the setting, and after fully and uniformly melting, use the gas atomization method to obtain 4D printing titanium-nickel shape memory alloy powder, and then sieve the powder after drying to obtain the powder with the required particle size;

[0045]Adjust the SLM equipment, and pour the 4D printed titanium-nickel shape memory alloy powder into the powder feeding cylinder or the powder hopper. The scanning range is controlled within the geometric range of the substrate;

[0046] Laser processing and forming, that is, the SLM control system first uses the laser to repeatedly scan the substrate and preheat, and then spread powder and perform SLM printing and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com