Object Of Additive Manufacture With Encoded Predicted Shape Change And Method Of Manufacturing Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Formation of a Cube

[0123]In this example, a generally cylindrical object transforms into a first generation of a fractal Hilbert curve in the shape of a cube.

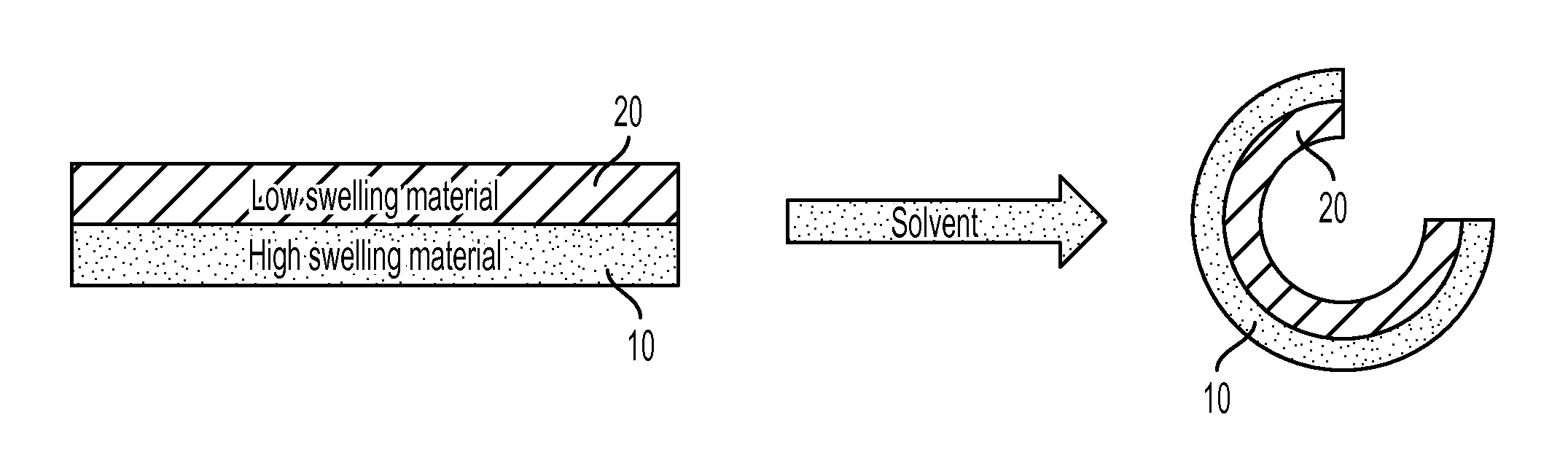

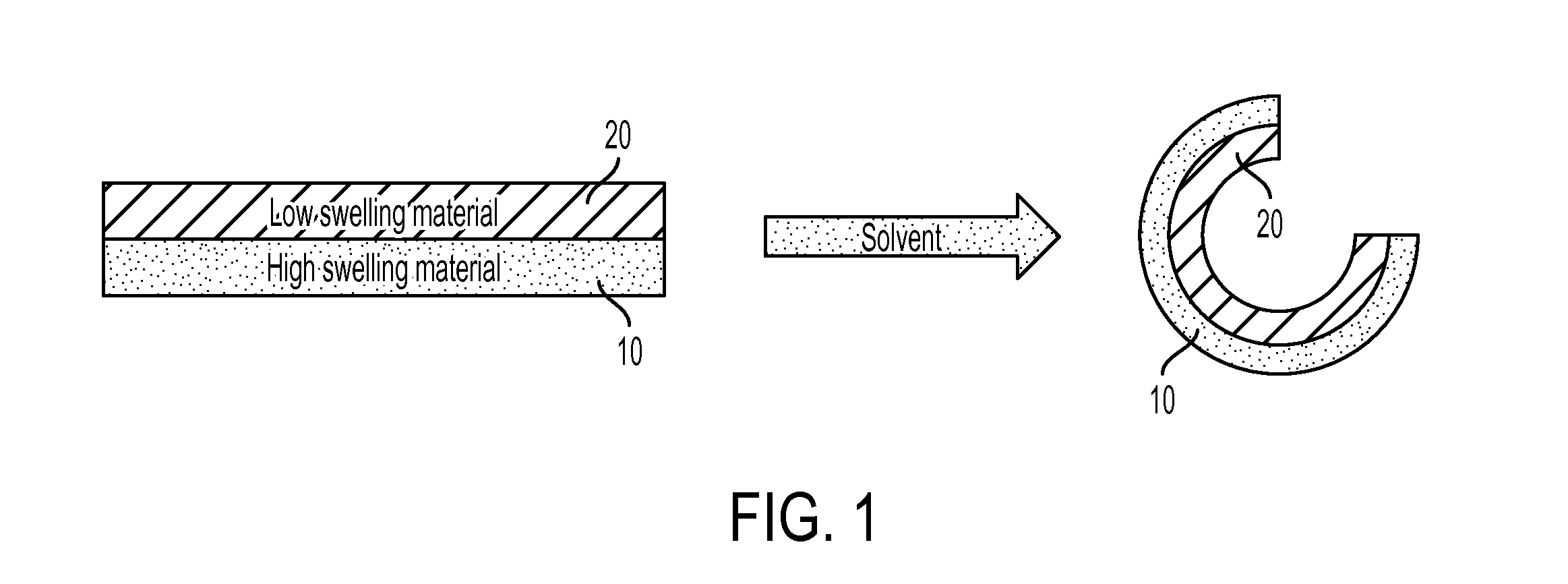

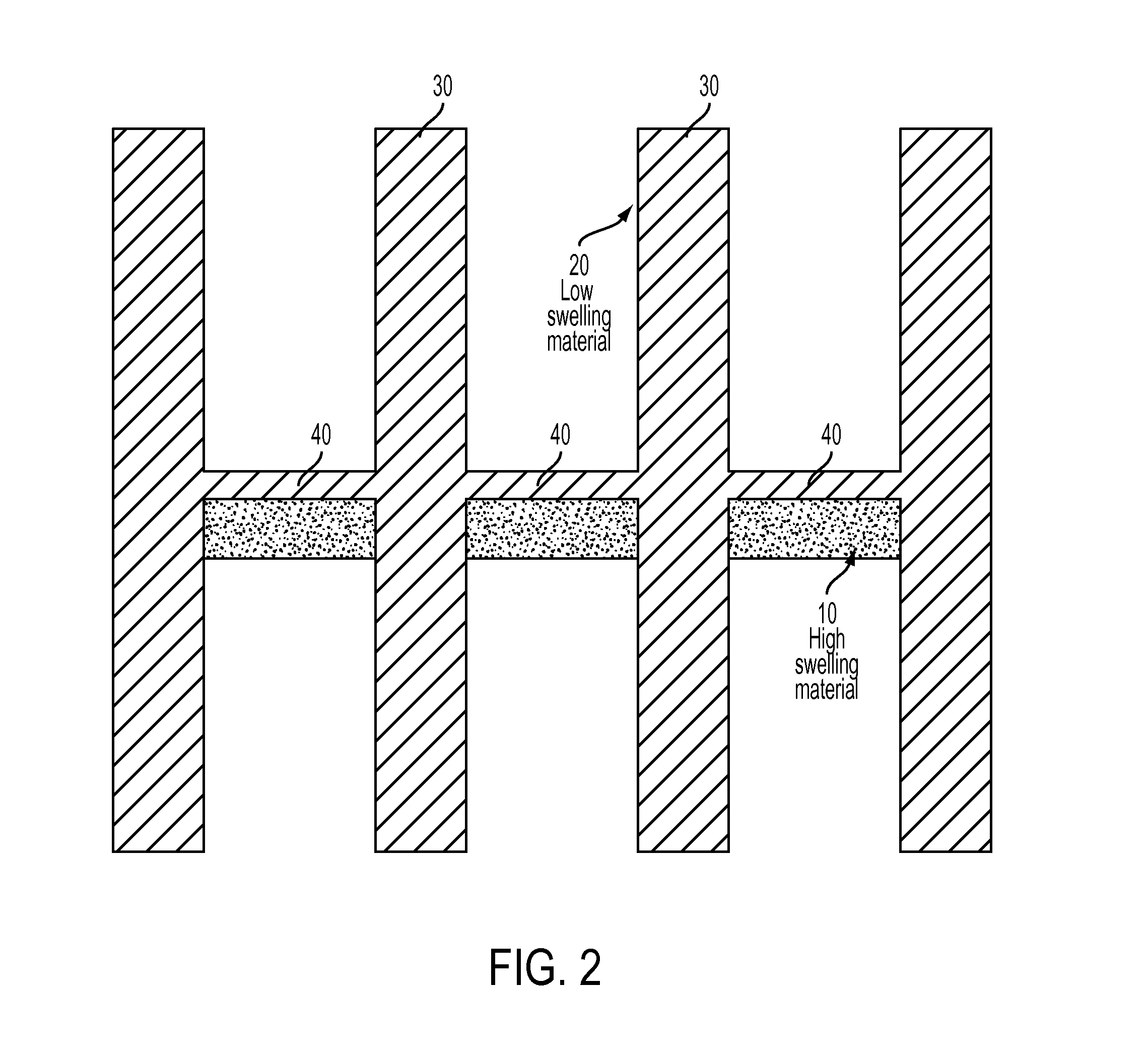

[0124]FIG. 2 is a schematic representation of an arrangement of a low swelling material and a high swelling material that can form a folding joint. The object has a generally cylindrical shape. Two cylindrical discs 30 are spaced apart by a horizontal member 40. The high swelling material 10 is placed on one side of the horizontal member 40. The cylindrical discs 30 and horizontal members 40 are made of a low swelling material. For example, the high swelling material can be more hydrophilic than the low swelling material. Stated differently, the low swelling material can be more hydrophobic than the high swelling material. The cylindrical discs 30 function as angle limiters. Upon exposure to an external stimulus, the cylindrical discs 30 force the joint to fold to an approximately 90° angle. In order to change the curvature of ...

example 2

Transformation from a Cylinder to Letters

[0129]In this example, a generally cylindrical object transforms into a series of letters that spell “MIT.”

[0130]FIG. 6 is a table having four columns that: A) describe a type of joint; B) provide a computer aided design (CAD) of the joint; C) show an experimental representation of the joint after exposure to an external stimulus; and D) illustrate a simulation showing the predicted shape of the joint after exposure to an external stimulus. Each of the joints in FIG. 6 can be used to curve an object of additive manufacture upon exposure to an external stimulus. Each of the joints has a different arrangement of high swelling material 10 and low swelling material 20, and thus each joint curves differently, as are illustrated in the experimental and simulated curvature (columns C and D). The joint designated Elbow-“bi” is particularly effective for creating larger curvatures, though each of the joints listed, as well as modifications and hybrids...

example 3

Formation of a Cube with Solid Sides

[0134]This example demonstrates surface transformations. A two-dimensional flat plane was printed. The flat plane corresponds to the six unfolded surfaces of a cube. At each of the joints, a strip of high and low swelling material is arranged so that the object transforms from a first shape to a second shape upon exposure to an external stimulus. The arrangement of high and low swelling material at each joint enables a 90° curvature so that the faces of the cube curve toward each other and stop curving upon reaching the second, predetermined shape. When submerged in water, the first shape transforms into a closed surface cube with filleted edges.

[0135]FIGS. 9A-F are schematic representations of an object of additive manufacture that can transform into a cube having solid sides after exposure to an external stimulus. FIG. 9A is a top view of the object, which is formed from six panels 320, one for each face of the cube, with joints that fold upon e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com