Magnetic iron-based resin material, and preparation method and application thereof

A resin material and iron-based technology, applied in coatings, medical science, prostheses, etc., can solve the problems of increasing patient pain, alveolar bone damage, etc., and achieve the effects of prolonging the life of dentures, simplifying the process, and being human-friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a magnetic iron-based resin material, which is used for tooth restoration, especially for the preparation of dentures. The method comprises the following steps:

[0037] (1) reducing the ferrous sulfate reaction solution to obtain iron particles;

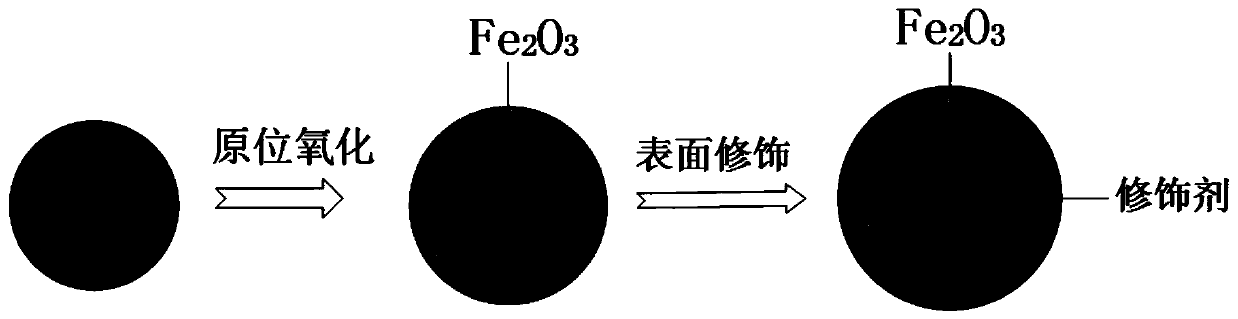

[0038] (2) in-situ oxidation of iron particles to obtain oxidized iron particles;

[0039] (3) using a modifier to modify the surface of the oxidized iron particles to obtain surface-modified iron particles;

[0040] (4) Coating the surface-modified iron particles with resin to obtain a magnetic iron-based resin material.

[0041] The ferromagnetic iron-based resin material provided by the present invention contains iron particles capable of magnetically adsorbing with magnets or permanent magnets, and the iron particles are used as cores, and are gradually modified and wrapped to obtain a ferromagnetic iron-based resin material.

[0042] There are many ways to obtain iron parti...

Embodiment 1

[0101] Strong magnetic iron-based resin material (oleic acid surface modification):

[0102] a Reduction of FeSO using NaBH4 4 , to get Fe particles.

[0103] Preparation of reaction solution and reducing solution

[0104] Reaction solution: FeSO 4 ·7H 2O, 0.1mol / L×100ml, used after preparation Medium-speed qualitative filter paper filtration.

[0105] Reducing solution: NaBH 4 , 0.5mol / L×40ml+60ml NH 3 ·H 2 O, the two are fully mixed before use.

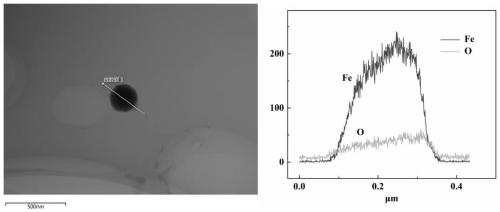

[0106] Use a constant flow pump to drop the mixed reducing solution into the reaction solution and stir continuously, the titration rate is 3ml / min; heat in a water bath at a temperature of 40°C; generate Fe particles with a particle size of about 200nm.

[0107] B In-situ oxidation: Add 30% hydrogen peroxide dropwise into the solution after the reaction in a, the titration rate is 2.5ml / min, and the total amount is 5ml to form Fe particles after surface oxidation.

[0108] c surface modification: add 0.25ml oleic acid to...

Embodiment 2

[0112] Strong magnetic iron-based resin material (surface modification with stearic acid):

[0113] a Reduction of FeSO using NaBH4 4 , to get Fe particles.

[0114] Preparation of reaction solution and reducing solution

[0115] Reaction solution: FeSO 4 ·7H 2 O, 0.1mol / L×100ml, used after preparation Medium-speed qualitative filter paper filtration.

[0116] Reducing solution: NaBH 4 , 0.5mol / L×40ml+60ml NH 3 ·H 2 O, use after mixing well.

[0117] Use a constant flow pump to drop the mixed reducing solution into the reaction solution and stir continuously, the titration rate is 3ml / min; heat in a water bath at a temperature of 40°C; generate Fe particles with a particle size of about 200nm.

[0118] B In-situ oxidation: Add 30% hydrogen peroxide dropwise into the solution after the reaction in a, the titration rate is 2.5ml / min, and the total amount is 5ml to form Fe particles after surface oxidation.

[0119] c surface modification: add 0.5ml stearic acid to b t...

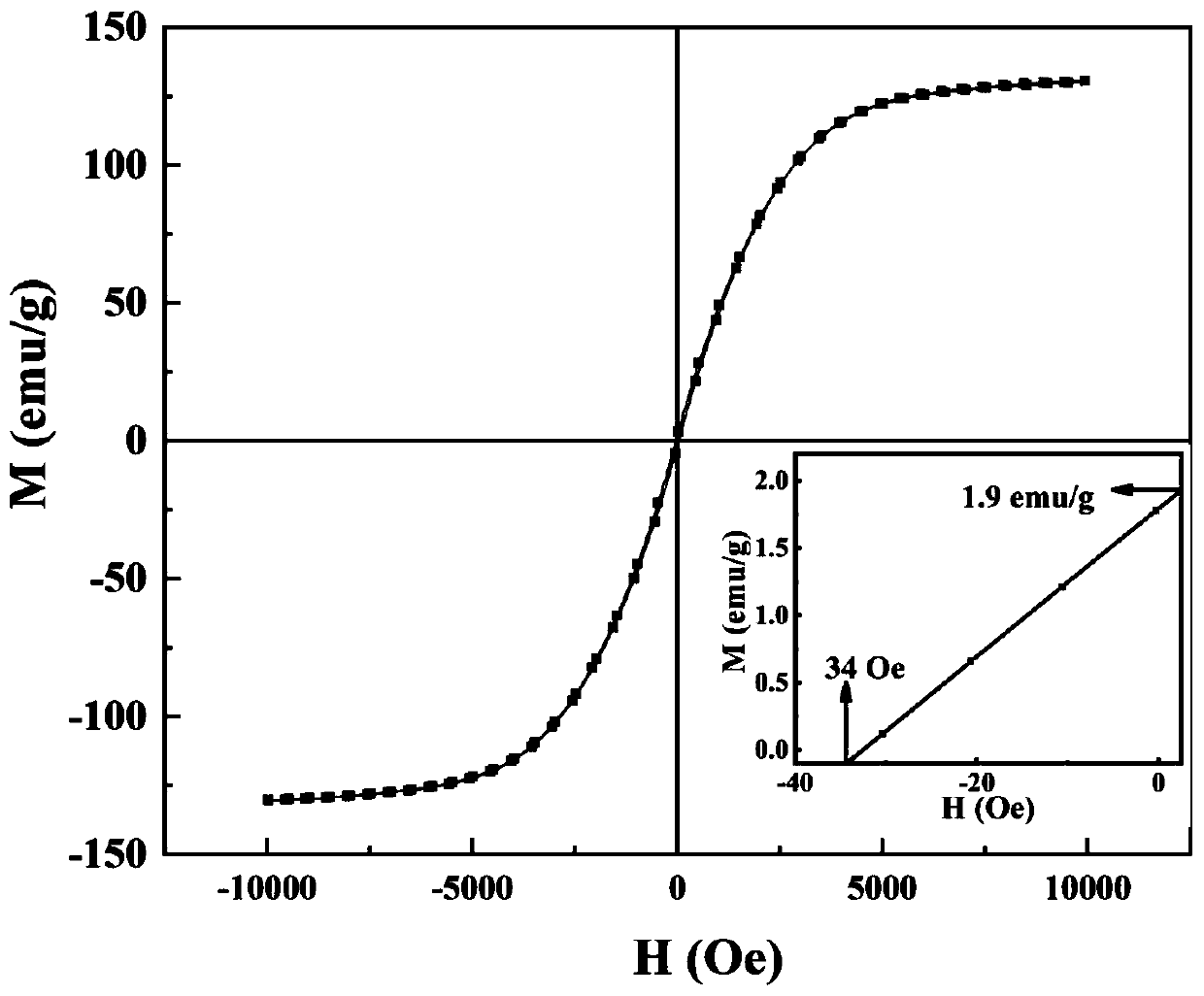

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com