Method for simply and stably preparing micro-nano hollow copper

A micro-nano and stable technology, applied in nanotechnology and other directions, can solve the problems of complex and difficult operation and difficult to achieve scale, and achieve the effect of simple operation method, low preparation cost and good gas sensing characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: The preparation method of the micro-nano copper particles includes: using copper sulfate, polyvinylpyrrolidone, sodium hydroxide and hydrazine hydrate as raw materials to generate micro-nano copper with a hollow structure through reaction;

[0020] Specific steps are as follows:

[0021] (1) 0.16g copper sulfate (Cu SO 4 ) into 100ml of water, put into a water bath and heat;

[0022] (2) Add 0.18g polyvinylpyrrolidone (PVP, k30, molecular weight 50000) into the above solution and stir vigorously;

[0023] (3) 1.5g sodium hydroxide is added into 25ml water, is made into the aqueous solution of sodium hydroxide, then adds in the described solution of step (2), stirs;

[0024] (4) Add 2ml of hydrazine hydrate aqueous solution prepared in advance at 1:15 into the solution described in step (3), and stir;

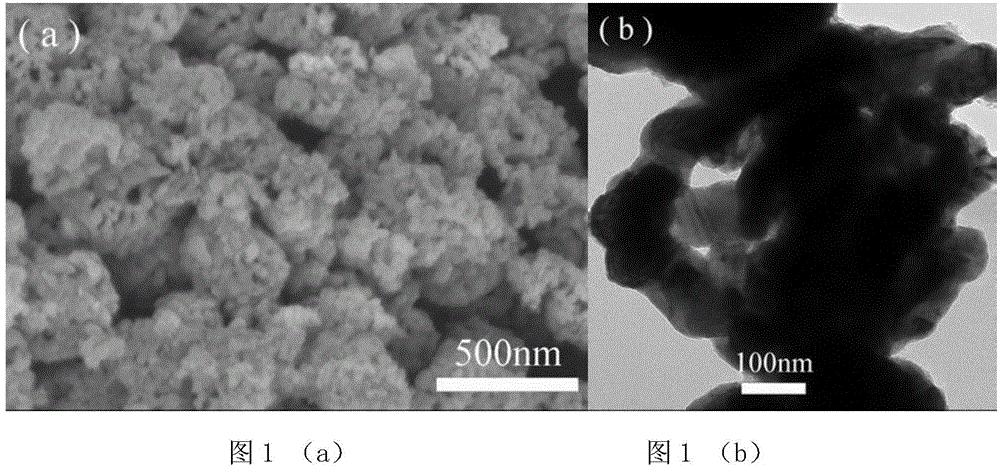

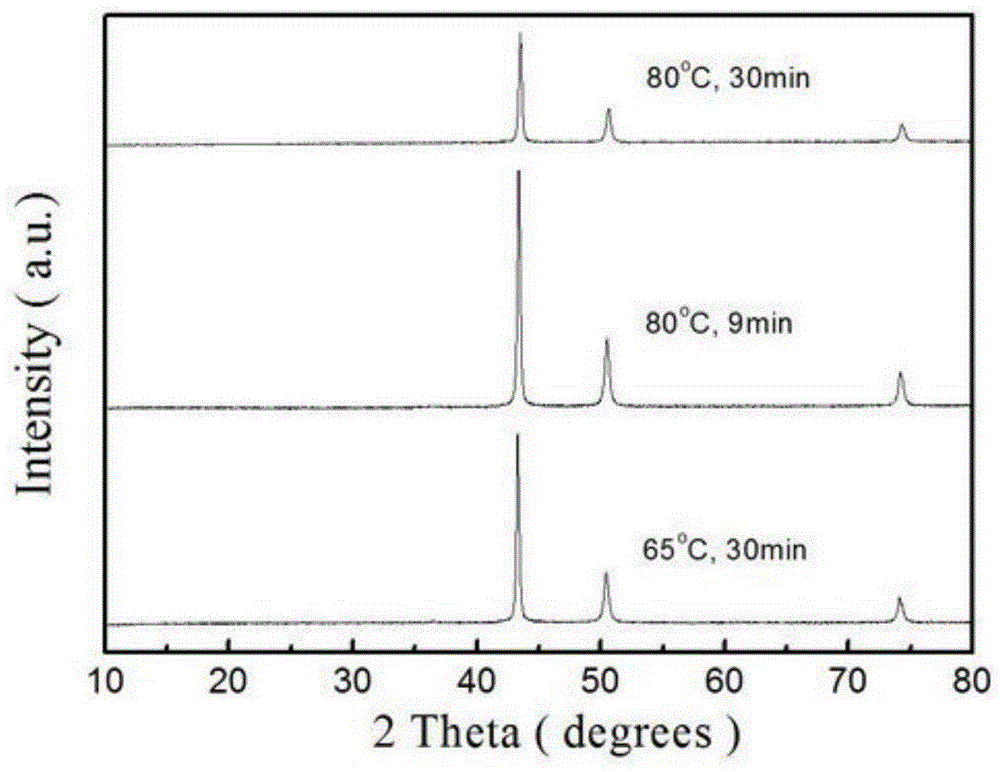

[0025] (5) Adjust the temperature of the water bath to 65°C, react for 30 minutes, and tan Cu particles are formed, and the solid-liquid two-phase contai...

Embodiment 2

[0027] Embodiment 2: The specific steps of the micronano copper particle preparation method are as follows:

[0028] (1) 0.16g copper sulfate (CuSO 4 ) into 100ml of water, put into a water bath and heat;

[0029] (2) Add 0.18g polyvinylpyrrolidone (PVP, k30, molecular weight 50000) into the above solution and stir vigorously;

[0030] (3) 1.5g sodium hydroxide is added into 25ml water, is made into the aqueous solution of sodium hydroxide, then adds in the described solution of step (2), stirs;

[0031] (4) Add 2ml of hydrazine hydrate aqueous solution prepared in advance at 1:15 into the solution described in step (3), and stir;

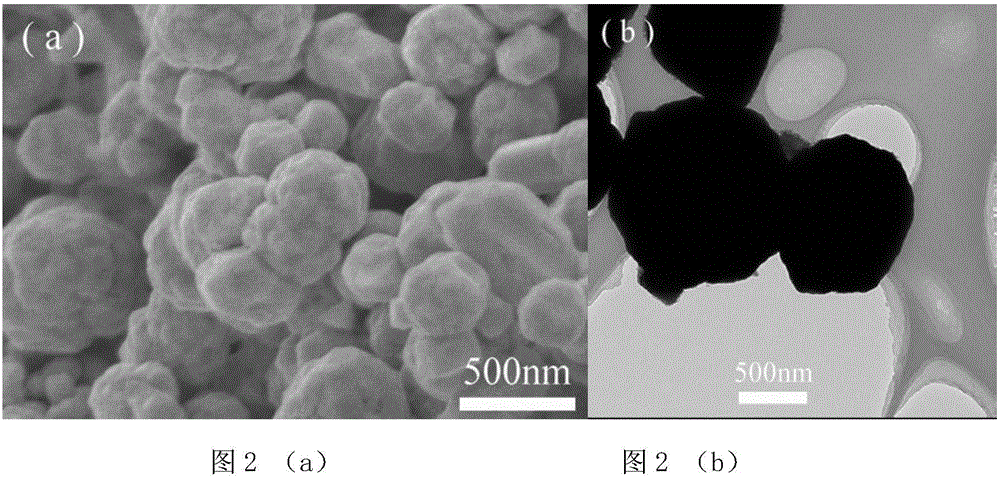

[0032] (5) Adjust the temperature of the water bath to 80°C, react for 9 minutes, and tan Cu particles are formed, and the solid-liquid two-phase containing Cu particles is centrifuged at high speed to obtain Cu solid particles, and then use absolute alcohol and deionized Water cross-washes Cu particles several times to remove other impurities i...

Embodiment 3

[0034] Embodiment 3: The specific steps of the preparation method of the micro-nano copper particles are as follows:

[0035] (1) 0.16g copper sulfate (Cu SO 4 ) into 100ml of water, put into a water bath and heat;

[0036] (2) Add 0.18g polyvinylpyrrolidone (PVP, k30, molecular weight 50000) into the above solution and stir vigorously;

[0037] (3) 1.5g sodium hydroxide is added into 25ml water, is made into the aqueous solution of sodium hydroxide, then adds in the described solution of step (2), stirs;

[0038] (4) Add 2ml of hydrazine hydrate aqueous solution prepared in advance at 1:15 into the solution described in step (3), and stir;

[0039] (5) Adjust the temperature of the water bath to 80°C, react for 30 minutes, and tan Cu particles are formed, and the solid-liquid two-phase containing Cu particles is centrifuged at high speed to obtain Cu solid particles, and then use absolute alcohol and deionized Water cross-washes Cu particles several times to remove other i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com