Tin dioxide nanoflower with hollow structure and preparation method of tin dioxide nanoflower

A technology of tin dioxide and hollow structure, which is applied in the field of nanomaterials, can solve the problems of complex operation, high cost, and inability to prepare tin dioxide nanoparticles with complex shapes, and achieve good repeatability, easy operation, and good monodispersity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the above-mentioned hollow structure tin dioxide nanoflowers comprises the following steps:

[0034] Step 1, preparing solid zinc stannate nanoflowers:

[0035] ZnO, SnCl 4 , NaOH and CTAB are dissolved in water, generally using deionized water, stirring evenly, the stirring speed is generally 1200-1600r / min, and the time is generally 10-40min to obtain a mixed solution, the concentration of ZnO in the mixed solution is 0.003-0.005 mol / L, SnCl 4 The concentration of NaOH is 0.01-0.03 mol / liter, the concentration of CTAB is 0.01-0.03 mol / liter, the concentration of NaOH is 0.1-0.2 mol / liter, and then the mixed solution is moved into the hydrothermal reaction kettle, 160-200 ℃, the reaction After 10-16 hours, the obtained precipitate was washed by centrifugation with deionized water and absolute ethanol three times respectively (centrifugation speed 6500 rpm, centrifugation time 3 minutes), and then dried at 60°C to obtain solid zinc stannate ...

Embodiment 1

[0045] Step 1. Weigh 13mg of ZnO, 240mg of NaOH, 292mg of CTAB and 210mg of SnCl respectively 4 , add 40mL of deionized water, stir at 1600r / min for 10min and mix well to obtain a mixed solution, then transfer the mixed solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 12h. Ethanol was centrifuged and washed three times, and then dried at 60°C in an air atmosphere to obtain solid zinc stannate nanoflowers;

[0046] Step 2: Perform high-temperature annealing treatment on the solid zinc stannate nanoflowers at 850° C. in an air atmosphere for 30 minutes, and obtain solid mixed nanoflowers after cooling;

[0047] Step 3: Dissolving 50 mg of solid mixed nanoflowers in 5 mL of 0.25 M nitric acid aqueous solution, standing still for 24 hours, separating, centrifuging and washing with deionized water, and drying at 60° C. to obtain tin dioxide nanoflowers with a hollow structure.

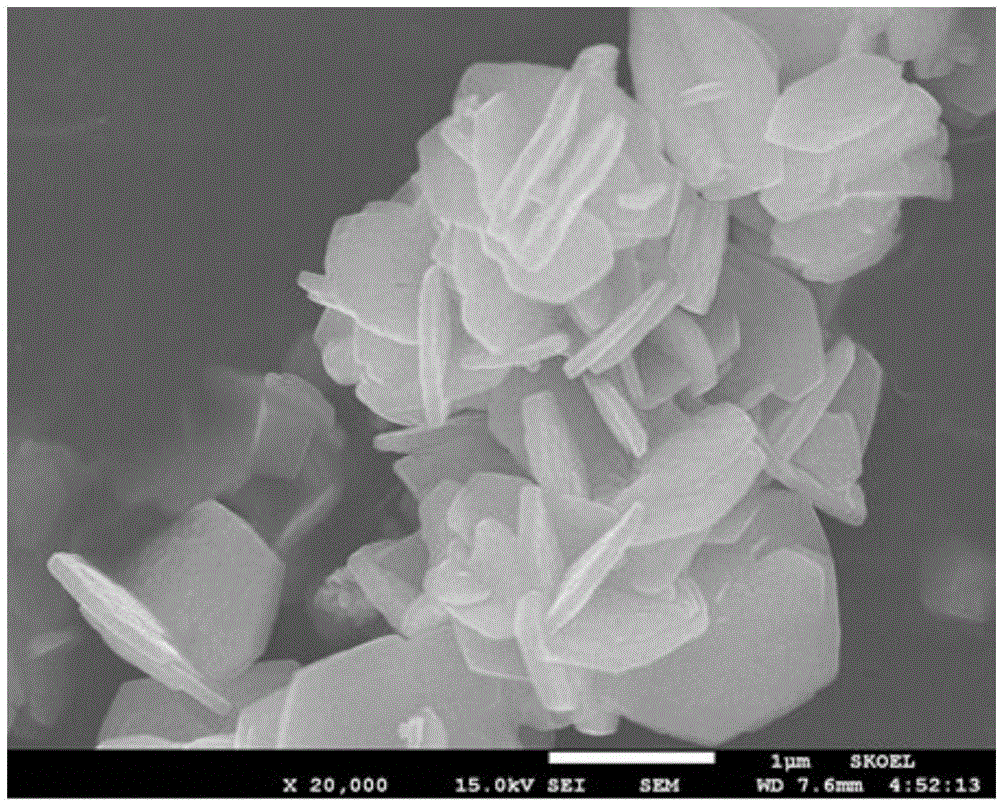

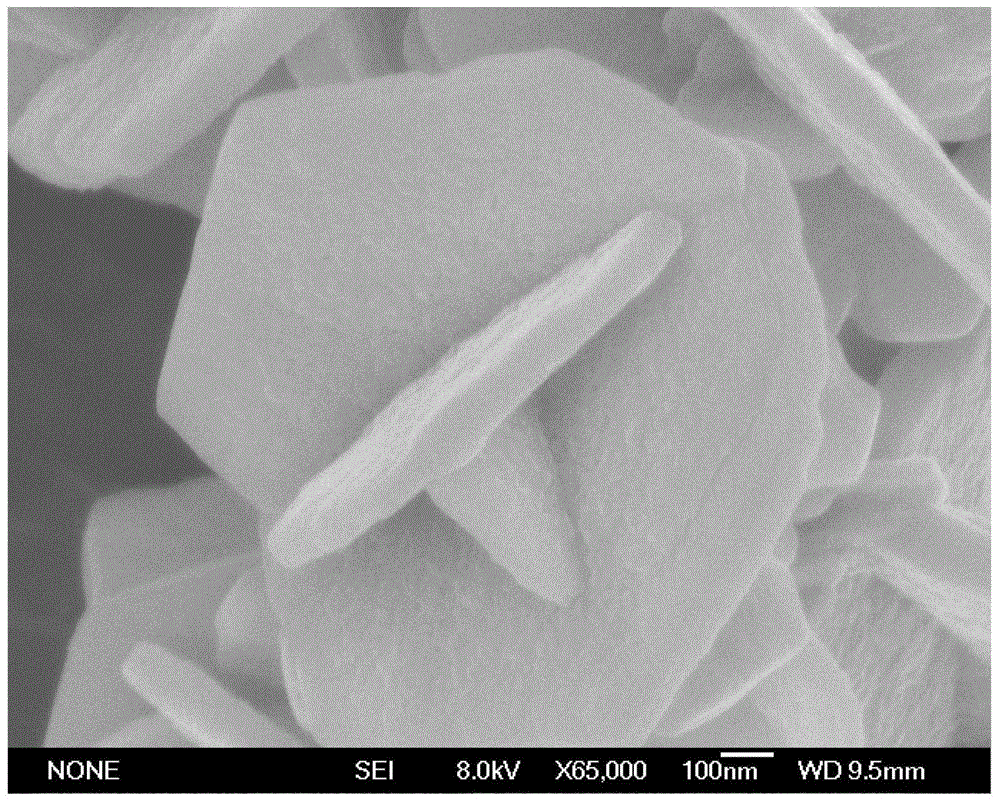

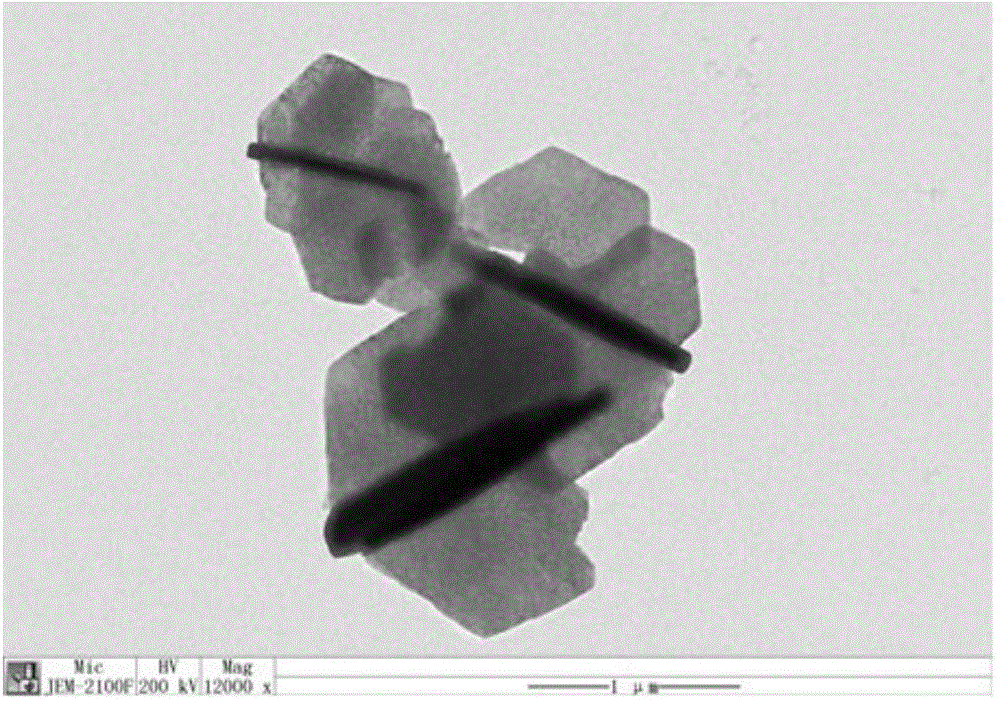

[0048] The morphology of solid zinc stannate nanoflowers, s...

Embodiment 2

[0053] Step 1. Weigh 13mg of ZnO, 240mg of NaOH, 292mg of CTAB and 210mg of SnCl respectively 4 , add 40mL of deionized water, stir at 1500r / min for 10min and mix well to obtain a mixed solution, then transfer the mixed solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 16h. Ethanol was centrifuged and washed three times, and then dried at 60°C in an air atmosphere to obtain solid zinc stannate nanoflowers;

[0054] Step 2. Perform high-temperature annealing treatment on the solid zinc stannate nanoflowers at 700° C. in an air atmosphere for 3 hours, and obtain solid mixed nanoflowers after cooling;

[0055] Step 3: Dissolving 50 mg of solid mixed nanoflowers in 5 mL of 0.5 M nitric acid aqueous solution, standing still for 48 hours, separating, washing with deionized water, and drying at 60° C. to obtain tin dioxide nanoflowers with a hollow structure.

[0056] After testing, the specific surface area of the nanoflowers obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com