Carbon fiber grid, preparation method thereof, composite material and preparation of composite material

A composite material and carbon fiber technology, which is applied in the fields of carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of inability to achieve effective chemical connection, failure to meet mechanical performance requirements, and many inorganic components, so as to meet the requirements of mechanical performance and improve Mechanical properties, the effect of increasing the grip force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

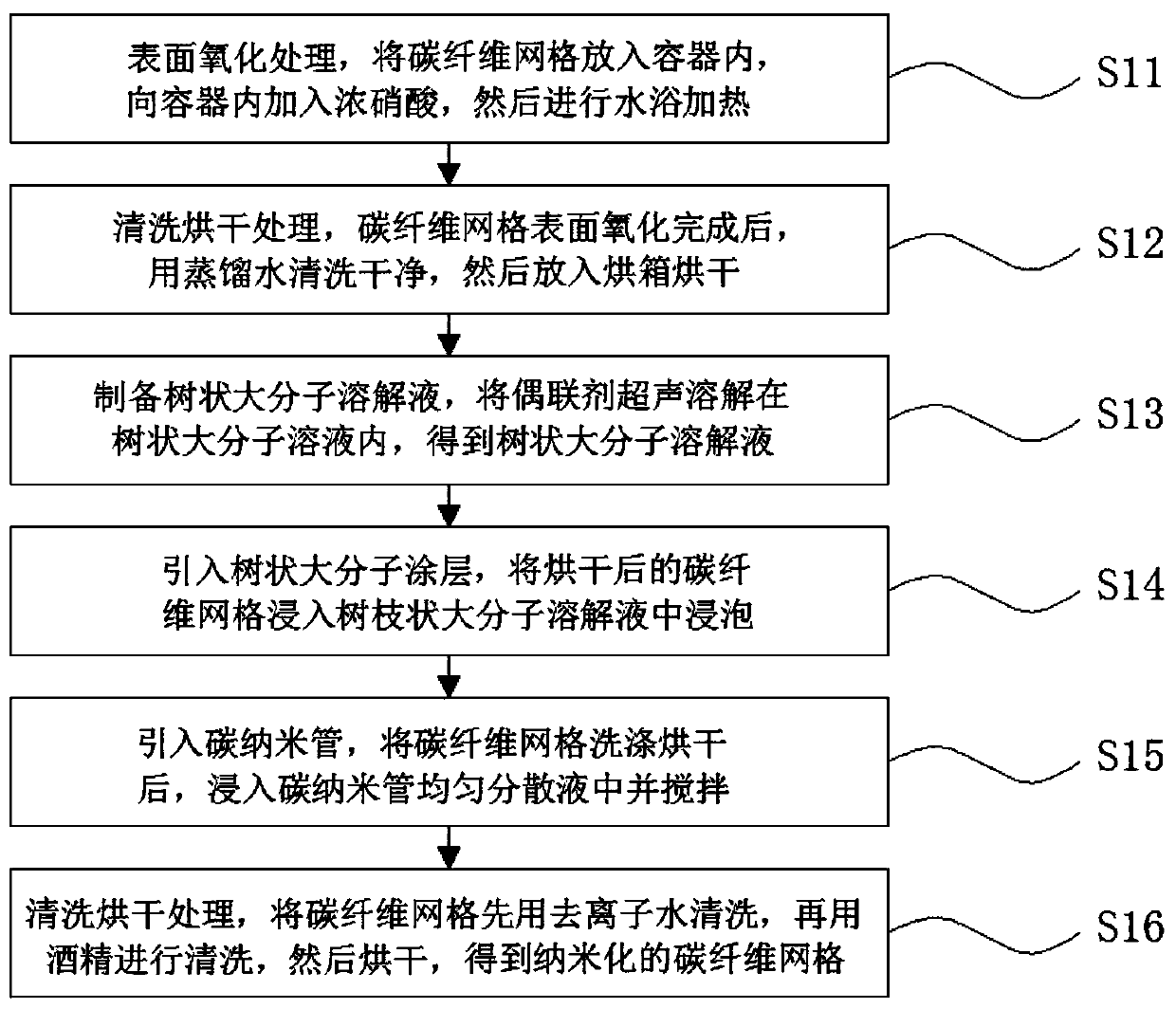

[0039] Please refer to figure 1 , a flowchart of a method for preparing a carbon fiber grid provided in this embodiment, comprising the following steps:

[0040] S11 surface oxidation treatment, put a suitable cut carbon fiber grid into a beaker, add concentrated nitric acid with a mass fraction of 69% into the beaker, and then heat it in a water bath at 100 ° C for 12 hours, the carbon fiber grid is oxidized by nitric acid to remove the surface of the carbon fiber grid Primer, increase the roughness of the carbon fiber surface, introduce polar groups such as carboxyl groups on the carbon fiber surface, increase the surface chemical activity of the carbon fiber grid;

[0041] S12 cleaning and drying treatment, after the carbon fiber grid surface is oxidized, rinse it off with distilled water for 4-5 times, then put it in an oven, and dry it at 40 °C for 3 hours;

[0042] S13 Preparation of dendrimer (PAMAM) solution, 0.05g of dendrimer (PAMAM) and 0.005g of methyl ammonia hex...

Embodiment 2

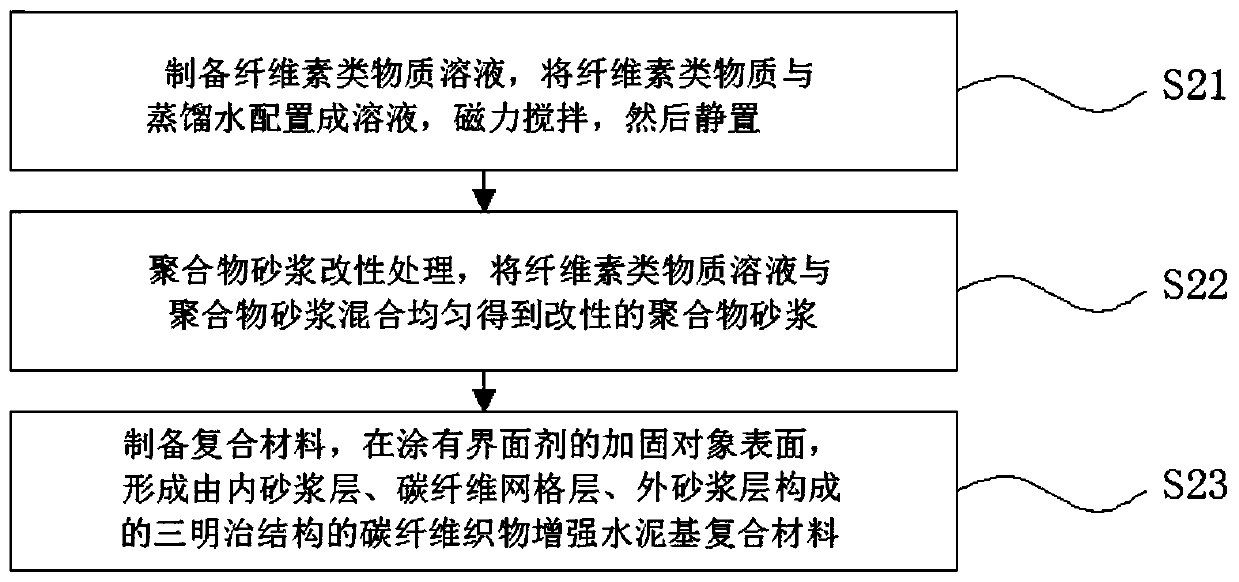

[0048] Please refer to figure 2 , a schematic flowchart of a composite material preparation method provided in this embodiment, comprising the following steps:

[0049] S21 Prepare a cellulose-based substance solution, dissolve 294 mg of cellulose in 98 g of distilled water, stir magnetically at 40°C for 2 h, and let stand for 10 min to obtain a cellulose-based substance solution;

[0050] S22 polymer mortar modification treatment, mixing the above-mentioned cellulose substance solution with 600g polymer mortar uniformly to obtain a modified polymer mortar;

[0051] S23 Prepare the composite material, coat the modified polymer mortar on the surface of the reinforcement object coated with the interface agent, form an inner mortar layer with a thickness of 4-6mm, and then flatten the nano-sized carbon fiber grid obtained in Example 1. On the inner mortar layer, a carbon fiber grid layer is formed, and then the modified polymer mortar is coated on the carbon fiber grid layer to...

Embodiment 3

[0056] Please refer to figure 1 , a flowchart of a method for preparing a carbon fiber grid provided in this embodiment, comprising the following steps:

[0057] S11 surface oxidation treatment, put a suitable cut carbon fiber grid into a beaker, add concentrated nitric acid with a mass fraction of 69% into the beaker, and then heat it in a water bath at 100 ° C for 12 hours, the carbon fiber grid is oxidized by nitric acid to remove the surface of the carbon fiber grid Primer, increase the roughness of the carbon fiber surface, introduce polar groups such as carboxyl groups on the carbon fiber surface, increase the surface chemical activity of the carbon fiber grid;

[0058] S12 cleaning and drying treatment, after the carbon fiber grid surface is oxidized, rinse it off with distilled water for 4-5 times, then put it in an oven, and dry it at 40 °C for 3 hours;

[0059] S13 Prepare dendrimer (PAMAM) solution, dissolve 0.1g dendrimer (PAMAM) and 0.005g methylaminohexaoxophosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com