Composite-carrier honeycomb monolithic denitration catalyst and preparing method thereof

A technology of denitrification catalyst and composite carrier, which is applied in the field of honeycomb monolithic SCR denitrification catalyst and its preparation, can solve the problems of high price and unstable mechanical properties, and achieve the effect of low raw material cost, reduced catalyst cost and good NO removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

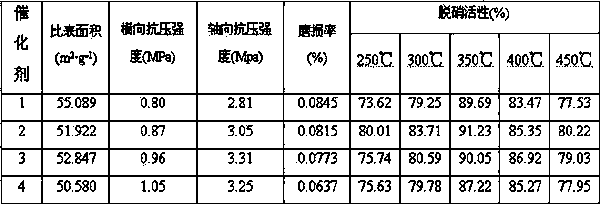

Examples

Embodiment 1

[0020] (1) Weigh 2kg of cordierite powder, soak in 15wt% sulfuric acid solution at room temperature for 6 hours, dry at 50°C for 2 hours, and dry at 110°C for 5 hours to obtain modified cordierite powder for use.

[0021] (2) Take 0.216kg of oxalic acid and 2200mL of water in a large beaker, then weigh 0.216kg of ammonium metavanadate into it, heat at 60°C for 18 minutes to prepare a catalyst active solution for later use.

[0022] (3) Weigh 1.62 kg of modified cordierite powder, 0.162 kg of polyvinyl alcohol, 0.32 kg of glass fiber and 13.682 kg of titanium-tungsten powder and pour them into the mixer for stirring. ammonium vanadate solution and 1500 mL deionized water. Among them, titanium tungsten powder is titanium dioxide, which contains 3~10% WO 3 .

[0023] (4) After being fully stirred, after cooling and adjustment, the material shall be stale for 24 hours and then be extruded;

[0024] (5) Extrude the monolithic honeycomb catalyst from the extruder, dry at 90°C for...

Embodiment 2

[0026] (1) Weigh 3kg of cordierite powder, soak in 25wt% sulfuric acid solution at room temperature for 6 hours, dry at 60°C for 3 hours, and dry at 105°C for 5 hours to obtain modified cordierite powder for use.

[0027] (2) Take 0.268kg of oxalic acid and 2800mL of water in a large beaker, then weigh 0.268kg of ammonium metavanadate into it, heat at 85°C for 10 minutes to prepare a catalyst active solution for later use.

[0028] (3) Weigh 2.42 kg of modified cordierite powder, 0.49 kg of polyvinyl alcohol, 0.81 kg of glass fiber and 12.064 kg of titanium tungsten powder and pour them into the mixer for stirring. ammonium vanadate solution and 1000 mL deionized water. Among them, titanium tungsten powder is titanium dioxide, which contains 3~10% WO 3 .

[0029] (4) After being fully stirred, after cooling and adjustment, the material shall be stale for 24 hours and then be extruded;

[0030] (5) Extrude the monolithic honeycomb catalyst from the extruder, dry at 100°C for...

Embodiment 3

[0032] (1) Weigh 4kg cordierite powder, soak it in 35wt% sulfuric acid solution at room temperature for 7 hours, dry it at 50°C for 2 hours, and dry it at 110°C for 6 hours to obtain modified cordierite powder for use.

[0033] (2) Take 0.315 kg of oxalic acid and 3200 mL of water in a large beaker, then weigh 0.315 kg of ammonium metavanadate into it, heat at 75°C for 20 minutes to prepare a catalyst active solution for later use.

[0034](3) Weigh 3.23 kg of modified cordierite powder, 0.32 kg of polyvinyl alcohol, 0.81 kg of glass fiber and 11.424 kg of titanium-tungsten powder and pour them into the mixer for stirring. ammonium vanadate solution and 800 mL deionized water. Among them, titanium tungsten powder is titanium dioxide, which contains 3~10% WO 3 .

[0035] (4) After being fully stirred, after cooling and adjustment, the material shall be stale for 24 hours and then be extruded;

[0036] (5) Extrude the monolithic honeycomb catalyst from the extruder, dry at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com