Integral honeycomb denitration catalyst for novel WO3 addition technology and preparation method of catalyst

A denitrification catalyst and honeycomb technology, which is applied in the field of new compounding process catalyst and its preparation, can solve the problems of high catalyst cost and achieve good chemical stability, high specific surface area and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

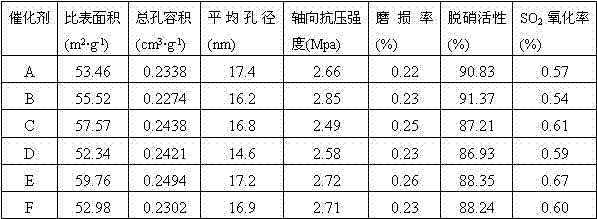

Examples

preparation example Construction

[0023] A kind of WO 3 The integral honeycomb denitration catalyst of the new additive process is composed of the following components by weight percentage: WO 3 4%~8%, V 2 o 5 1%-1.5%, TiO 2 80.5%~90%, binder 5%~10%; WO 3 The precursor solution is added in the process of catalyst mixing and sliming. The WO 3 A method for preparing a monolithic honeycomb denitration catalyst with a novel additive process, comprising the following steps:

[0024] 1) Weigh the tungsten salt precursor (ammonium metatungstate, ammonium tungstate or ammonium paratungstate) according to the WO in the catalyst 3 Based on the formula amount of 4%~8%, add appropriate amount of oxalic acid solution and heat at 60~85°C to prepare tungsten salt precursor solution; at the same time, weigh the catalyst active component precursor ammonium metavanadate, 2 o 5 Formula amount is 1%~1.5%, add appropriate amount of oxalic acid solution and heat at 60~85°C to prepare catalyst active solution;

[0025] 2...

Embodiment 1

[0030] 1) Preparation of tungsten salt precursor solution: Weigh 0.428kg of ammonium metatungstate, add 800mL of deionized water, heat to 65°C, and keep warm for 12 minutes to dissolve;

[0031] Preparation of active solution: weigh 0.131kg of ammonium metavanadate, add 1400mL of oxalic acid solution (10% concentration) and heat at 70°C for 15 minutes;

[0032] 2) Weigh 0.735kg of glass fiber (binder) and 8.706kg of industrial-grade anatase titanium dioxide, put them into the mixer and stir for 5 minutes, then add 280 mL of deionized water, and the above-mentioned tungsten salt precursor solution and active solution;

[0033] 3) After being fully stirred, after cooling and adjustment, the material shall be stale for 22 hours to be extruded;

[0034] 4) Extrude the monolithic honeycomb catalyst with the material that meets the requirements in the extruder, dry at 60°C for 1 hour, dry at 105°C for 2 hours, calcinate at 250°C for 3.5 hours, and calcinate at 530°C for 5 hours to o...

Embodiment 2

[0036] 1) Weigh 0.624kg of ammonium metatungstate, add 1200mL of deionized water, heat at 60°C, and keep warm for 15 minutes to dissolve to prepare a tungsten salt precursor solution; weigh 0.147kg of ammonium metavanadate, add 1500mL of oxalic acid solution (volume percentage is 10%) heated to prepare an active solution;

[0037] 2) Weigh 0.723 kg of binder (0.5 kg of glass fiber, 0.223 kg of carboxymethyl cellulose) and 8.649 kg of industrial grade anatase titanium dioxide, add them into the mixer and stir for 5 minutes, then add 220 mL of deionized water, tungsten salt Precursor solution and ammonium metavanadate active solution;

[0038] 3) After full stirring, after cooling and adjustment, the material will be stale for 20 hours and then be extruded;

[0039] 4) Extrude the monolithic honeycomb catalyst from the extruder, dry at 75°C for 1 hour, dry at 100°C for 2 hours, calcinate at 230°C for 4.5 hours, and calcinate at 550°C for 6 hours to obtain the finished catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com