Surface treatment agent and preparation method and application thereof

A technology of surface treatment agent and crosslinking agent, which is applied in the field of surface treatment agent and its preparation, can solve the problems that it is difficult to apply the surface treatment requirements of silicone rubber heat insulation layer, and the duration of physical treatment effect is short, so as to achieve easy operation and long application time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

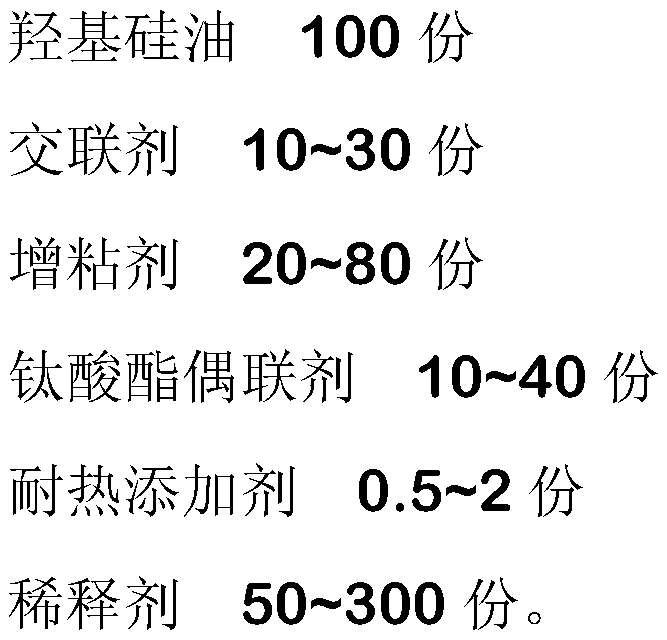

[0034] The composition of the surface treatment agent is as follows:

[0035] Hydroxyl silicone oil, hydroxyl value 6.0%, 100 parts; tetraethylorthosilicate, 20 parts; γ-aminopropyltriethoxysilane, 20 parts; tetrabutyl titanate, 10 parts; ferric oxide, 1.0 parts ; White carbon black 20 parts; Xylene, 200 parts.

[0036] The preparation method of the above-mentioned surface treatment agent, the steps of the method are: mixing hydroxy silicone oil, crosslinking agent, tackifier, titanate coupling agent, heat-resistant additive, white carbon black and diluent, and stirring uniformly to obtain surface treatment agent.

[0037] The application of a surface treatment agent in the bonding of the silicone rubber heat insulating layer and the butyl hydroxy lining layer, the steps are:

[0038] (1) Sandblasting or grinding the surface of the silicone rubber insulation layer;

[0039] (2) brushing the prepared surface treatment agent on the surface of the silicone rubber heat insulati...

Embodiment 2

[0043] The composition of the surface treatment agent is as follows:

[0044] Hydroxy silicone oil, hydroxyl value 4.0%, 100 parts; orthomethyl silicate, 10 parts; γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 10 parts; γ-aminopropyltriethoxy silane, 20 parts; tetrabutyl titanate, 30 parts; cerium oxide, 0.5 parts; ferric oxide 1.5 parts; toluene, 50 parts.

[0045] The preparation method of the above surface treatment agent comprises the following steps: mixing hydroxyl silicone oil, crosslinking agent, tackifier, titanate coupling agent, heat-resistant additive and diluent, and stirring evenly to obtain the surface treatment agent.

[0046] Surface treatment of the silicone rubber insulation layer and lining coating: After the silicone rubber insulation layer is sandblasted or polished, cleaned, and pre-baked, the surface treatment agent is brushed and left to air at 20°C for 1 hour. Brush or scrape butadiene polyurethane liner slurry on the surface of the heat insulation lay...

Embodiment 3

[0049]The composition of the surface treatment agent is as follows: hydroxy silicone oil, hydroxyl value 8.8%, 100 parts; tetraethyl orthosilicate, 10 parts; methyl triethoxysilane, 20 parts; γ-aminopropyl triethoxysilane, 60 parts Parts; tetraethyl titanate, 5 parts; tetraethyl titanate, 5 parts; tin dioxide, 0.5 parts; ferric oxide, 0.5 parts; white carbon black, 40 parts; toluene, 300 parts.

[0050] The preparation method of the above-mentioned surface treatment agent, the steps of the method are: mixing hydroxy silicone oil, crosslinking agent, tackifier, titanate coupling agent, heat-resistant additive, white carbon black and diluent, and stirring uniformly to obtain surface treatment agent.

[0051] Surface treatment of the silicone rubber insulation layer and lining coating: After the silicone rubber insulation layer is sandblasted or polished, cleaned, and pre-baked, the surface treatment agent is brushed and left to air for 1 hour at 25°C. Brush or scrape butadiene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com