Heavy metal repairing agent for soil and preparation method thereof

A technology of heavy metals and remediation agents, applied in the field of soil remediation, can solve the problems of low remediation efficiency, achieve the effects of improving porosity and specific surface area, improving complexation and fixation performance, and maintaining adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

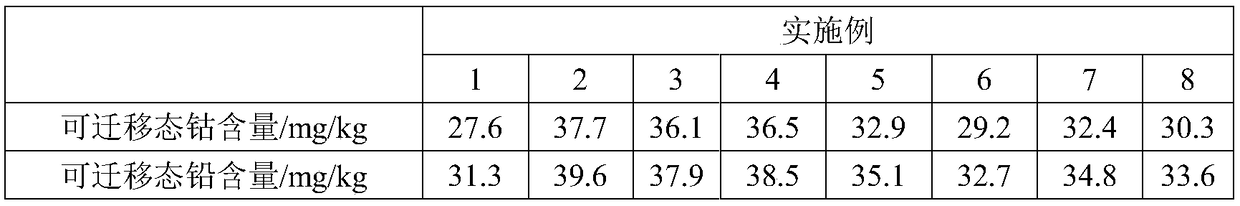

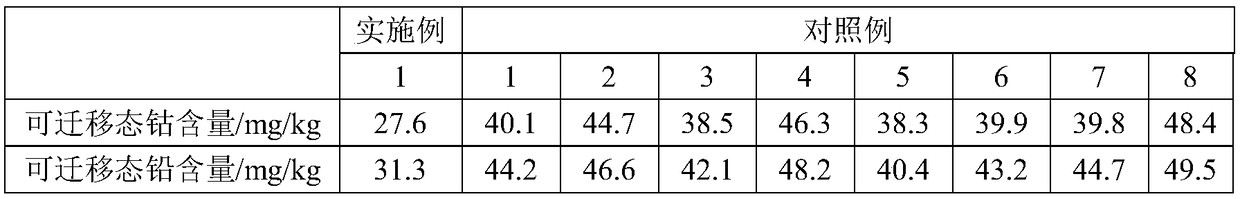

Examples

Embodiment 1

[0022] A kind of heavy metal remediation agent for soil, its preparation method comprises the following steps:

[0023] (1) Add 27 parts of montmorillonite and 39.5 parts of ethylenediaminetetraacetic acid into the hydrothermal reactor, maintain the system temperature at 209°C for 3.5 hours, add 28.7 parts of thioglycolic acid into the hydrothermal reactor, and maintain The hydrothermal reaction temperature was 121°C for 2.5 hours, 26.3 parts of ethylenediamine was added to the hydrothermal reaction kettle, the hydrothermal reaction temperature was maintained at 86°C for 45 minutes, and the hydrothermal reaction temperature was raised to 203°C After reacting for 1.5h, the product was ultrasonically washed 3 times with 500mL ethanol and dried to obtain modified montmorillonite;

[0024] (2) Add 38 parts of activated carbon, 18 parts of hydrogen peroxide and 9.8 parts of concentrated nitric acid into the hydrothermal reaction kettle, and keep the hydrothermal reaction temperatur...

Embodiment 2

[0029] A kind of heavy metal remediation agent for soil, its preparation method comprises the following steps:

[0030](1) Add 27 parts of montmorillonite and 37 parts of ethylenediaminetetraacetic acid into the hydrothermal reaction kettle, maintain the system temperature at 196°C for 4 hours, add 25 parts of thioglycolic acid into the hydrothermal reaction kettle, and maintain the water The thermal reaction temperature is 103°C for 3 hours, add 21 parts of ethylenediamine to the hydrothermal reaction kettle, maintain the hydrothermal reaction temperature at 73°C for 45 minutes, and raise the hydrothermal reaction temperature to 187°C for 2 hours , the product was ultrasonically washed 3 times with 500 mL of ethanol, and dried to obtain modified montmorillonite;

[0031] (2) Add 38 parts of activated carbon, 12 parts of hydrogen peroxide and 8 parts of concentrated nitric acid into the hydrothermal reaction kettle, and keep the hydrothermal reaction temperature at 87°C for 2 ...

Embodiment 3

[0036] A kind of heavy metal remediation agent for soil, its preparation method comprises the following steps:

[0037] (1) Add 27 parts of montmorillonite and 43 parts of ethylenediaminetetraacetic acid into the hydrothermal reaction kettle, maintain the system temperature at 217°C for 1 hour, add 34 parts of thioglycolic acid into the hydrothermal reaction kettle, and maintain the water The thermal reaction temperature is 128°C for 1 hour, add 30 parts of ethylenediamine to the hydrothermal reaction kettle, maintain the hydrothermal reaction temperature at 90°C for 45 minutes, and raise the hydrothermal reaction temperature to 210°C for 0.5 h, the product was ultrasonically washed 3 times with 500 mL of ethanol, and dried to obtain modified montmorillonite;

[0038] (2) Add 38 parts of activated carbon, 21 parts of hydrogen peroxide and 17 parts of concentrated nitric acid into the hydrothermal reaction kettle, and keep the hydrothermal reaction temperature at 103°C for 0.5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com