Low-temperature high-permeability soft magnetic manganese-zinc ferrite material and preparation method thereof

A technology of manganese-zinc ferrite and high magnetic permeability, applied in the direction of magnetism of inorganic materials, can solve the problems of low magnetic permeability and limit the application range of soft magnetic manganese-zinc ferrite materials, and achieve the effect of optimizing the sintering method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

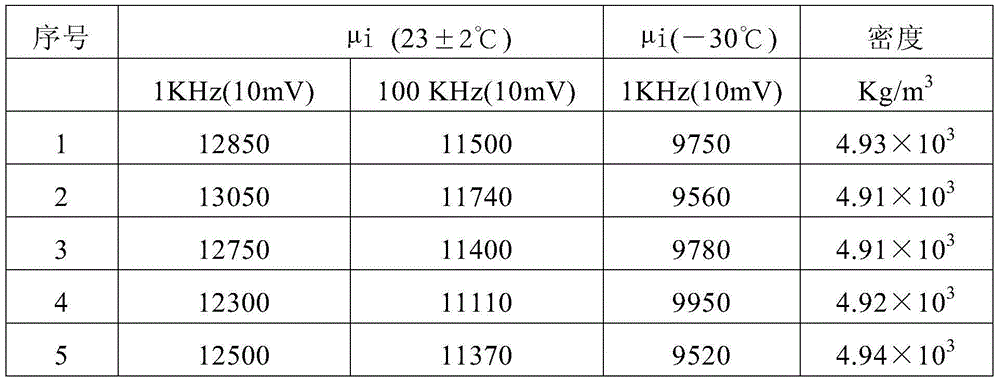

Examples

Embodiment 1

[0036] A method for preparing a wide-temperature high-permeability soft-magnetic manganese-zinc ferrite material with high magnetic permeability and good low-temperature characteristics, the specific steps are as follows:

[0037] (1) Mixing: Accurately weigh 51-55% iron oxide (Fe 2 o 3 ), 15-20% of zinc oxide (ZnO), and the rest of manganese oxide (MnO), using a strong mixer to mix evenly, the total mixing time is 2h, and the particle size of the mixed powder is controlled at about 1.0-1.4μm.

[0038] (2) Pre-burning: Put the above mixed powder into the rotary kiln for pre-burning, the pre-fired temperature is 800-950°C, the pre-fired time is 40-70 minutes, the flow rate of the mixed powder is controlled at about 6kg / min, and the rotary kiln speed is 5-20 rev / min, make the red mixed powder react initially in solid state, and make the mixed powder change from red to black.

[0039] (3) Coarse crushing: Add the black mixture obtained by pre-calcination into a vibrating ball m...

Embodiment 2~12

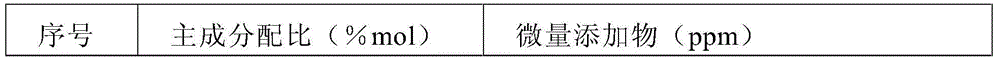

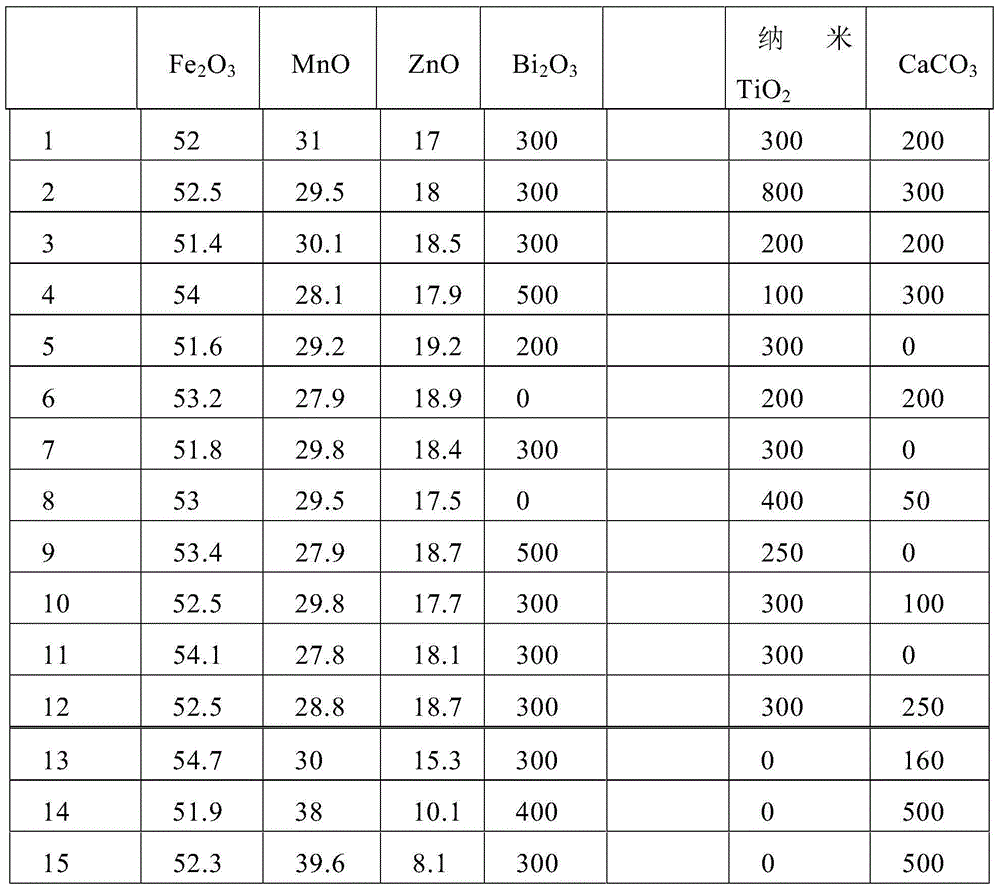

[0048] Using the steps and preparation method of Example 1, different proportions of main components and addition amounts of trace additives (as shown in Table 1) were selected to prepare samples respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com