Preparation method and application of two-dimensional lead telluride nano sheet and nano material

A nanomaterial, lead telluride technology, applied in the field of nanomaterials, can solve the problems of limiting the application of PbTe, poor process compatibility, high price, etc., and achieve the effects of good optoelectronic performance, low production equipment cost, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The following introduces the preparation method of the two-dimensional lead telluride nanosheet based on the above-mentioned growth system of the present invention, including:

[0041] 1) Weighing the reaction raw materials used for the growth of two-dimensional lead telluride nanosheets;

[0042] 2) Using sheet-like materials with atomic-level smooth surfaces as growth substrates;

[0043] 3) In the air flow of the protective gas, after the temperature is programmed, the reaction raw materials are heated at a constant temperature to perform vapor deposition;

[0044] 4) quenching the substrate after the deposition process is completed, that is, obtaining the two-dimensional lead telluride nanosheets on the substrate;

[0045] Specifically, the reaction raw materials include, but are not limited to, lead telluride powder, lead telluride block, tellurium simple substance, tellurium-containing compound, lead simple substance and / or lead-containing compound.

[0046] It ...

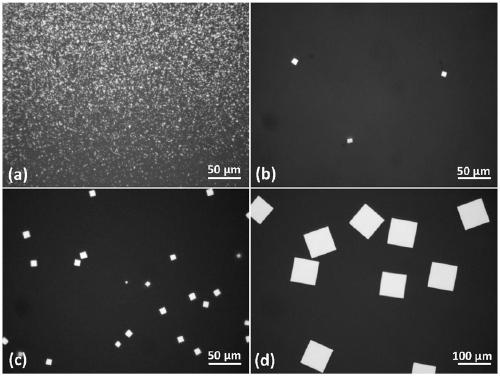

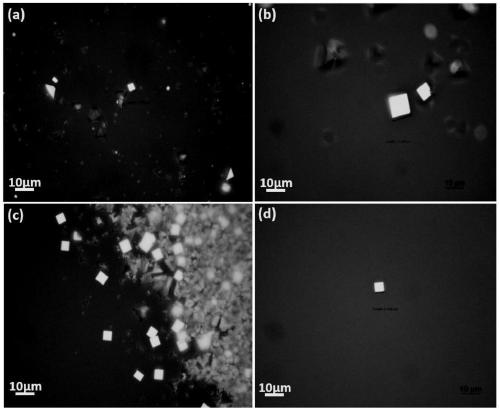

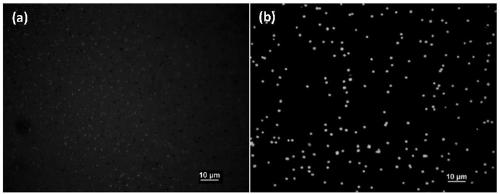

Embodiment 1

[0087] This embodiment discloses a method for preparing two-dimensional lead telluride nanosheets, which specifically includes:

[0088] (1) Preparation of mica sheet substrate

[0089] a) the mica sheet is divided into squares of 1.5cm*1.5cm;

[0090] b) Use a blade or scissors to dissociate the mica sheet from the middle into 3 to 4 pieces, and use the newly dissociated smooth plane as the growth surface.

[0091] (2) Weigh 400mg of PbTe powder, put it in a quartz boat, then connect the quartz boat with the magnet in the furnace with an iron wire, and put it into the upstream of the gas path of the horizontal tube furnace, specifically 40-50cm away from the heating center Use the magnet outside the furnace tube of the tube furnace to attract the magnet in the furnace; place the mica sheet in the downstream of the gas path of the horizontal tube furnace, specifically at a position 5-25cm away from the heating center;

[0092] (3) Utilize the vacuum pump to evacuate the hori...

Embodiment 2

[0103] This embodiment discloses a method for preparing two-dimensional lead telluride nanosheets, which specifically includes:

[0104] (1) Preparation of fluorine phlogopite sheet substrate

[0105] a) Divide the fluorphlogopite sheet into squares of 1.5cm*1.5cm;

[0106] b) Use a blade or scissors to peel off the fluorophlogopite sheet along the (001) surface into 3-4 pieces, and use the newly dissociated smooth plane as the growth surface.

[0107] (2) Weigh 400mg of PbTe powder, put it in a quartz boat, then connect the quartz boat with the magnet in the furnace with an iron wire, and put it into the upstream of the gas path of the horizontal tube furnace, specifically 40-50cm away from the heating center Place the fluorophlogopite sheet in the downstream of the gas path of the horizontal tube furnace, specifically at a position 5-25cm away from the heating center;

[0108] (3) Utilize the vacuum pump to evacuate the horizontal tube furnace. When the pressure in the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com