High-density polyethylene flame-retardant sub-pipe and preparation method thereof

A technology of high-density polyethylene and burning sub-pipes, which is applied to tubular objects, other household appliances, applications, etc., can solve the problems that affect the use of polyethylene pipes, lose mechanical properties, and be prone to aging, etc., and achieve excellent ultraviolet shielding effect, Improve the chemical activity of the surface and improve the effect of tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

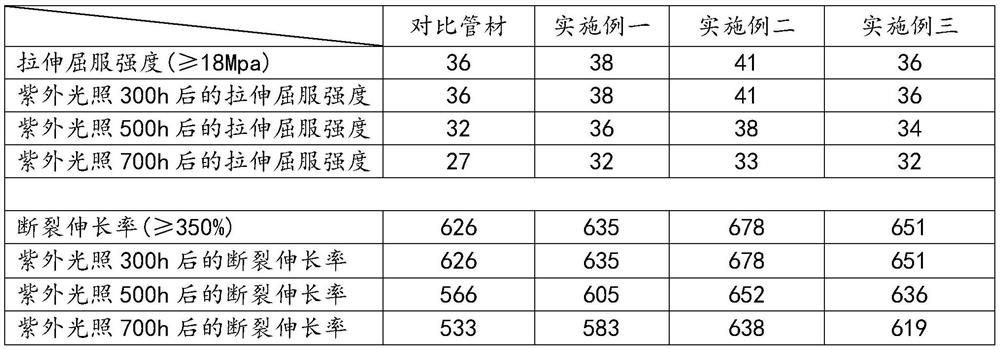

Examples

Embodiment 1

[0024] The high-density polyethylene flame-retardant sub-pipe of this embodiment has the following raw materials: 100 parts of high-density polyethylene, plasticizer, 1010 type antioxidant, 168 type antioxidant, calcium stearate, 58# paraffin, titanium dioxide, 2000 mesh Light calcium carbonate, halogenated hydrocarbons. Among them, the plasticizer is chlorinated polyethylene. The halogenated hydrocarbon is selected from dichloroethane, and the calcium stearate is selected as 1200 mesh.

[0025] The content ratio of the above-mentioned raw materials is: 100 parts of high-density polyethylene, 3 parts of plasticizer, 0.1 part of 1010 type antioxidant, 0.2 part of 168 type antioxidant, 0.3 part of calcium stearate, 0.2 part of 58# paraffin, titanium dioxide 8 parts, 4 parts of 2000-mesh light calcium carbonate, and 3 parts of halogenated hydrocarbons.

[0026] The preparation steps of the above-mentioned sub-tubes:

[0027] S1. Weigh the ingredients according to the parts by ...

Embodiment 2

[0036] The types of raw materials in this example are the same as those in Example 1, and the preparation method thereof is the same as that in Example 1, but with different proportions.

[0037] Among them, the content ratio of the raw materials in this example is: 100 parts of high-density polyethylene, 4 parts of plasticizer, 0.2 part of 1010 type antioxidant, 0.3 part of 168 type antioxidant, 0.6 part of calcium stearate, 0.5 part of 58# paraffin parts, 12 parts of titanium dioxide, 6 parts of 2000-mesh light calcium carbonate, and 5 parts of halogenated hydrocarbons.

Embodiment 3

[0039] The types of raw materials in this example are the same as those in Example 1, and the preparation method thereof is the same as that in Example 1, but with different proportions.

[0040] Wherein, the content ratio of the raw materials in this example is: 100 parts of high-density polyethylene, 6 parts of plasticizer, 0.8 part of 1010 type antioxidant, 1 part of 168 type antioxidant, 2 parts of calcium stearate, 3 parts of 58# paraffin wax parts, 15 parts of titanium dioxide, 8 parts of 2000-mesh light calcium carbonate, and 6 parts of halogenated hydrocarbons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com