Plastic deformation method for achieving structural performance optimization of inner surface of straight pipe

A technology of structural performance and plastic deformation, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as self-nano-system research on the inner surface of pipes, achieve uniform wall thickness and effective guarantee of collimation, and reduce grain size. Size, effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific technical solutions of the present invention will be described in conjunction with the specific embodiments.

[0021] The basic principle of optimizing the structural properties of the inner surface of the straight pipe of the present invention is to realize the refinement of the tissue structure and obtain the gradient deformation structure through high-speed, high-strain gradient plastic deformation. It mainly includes three technical links:

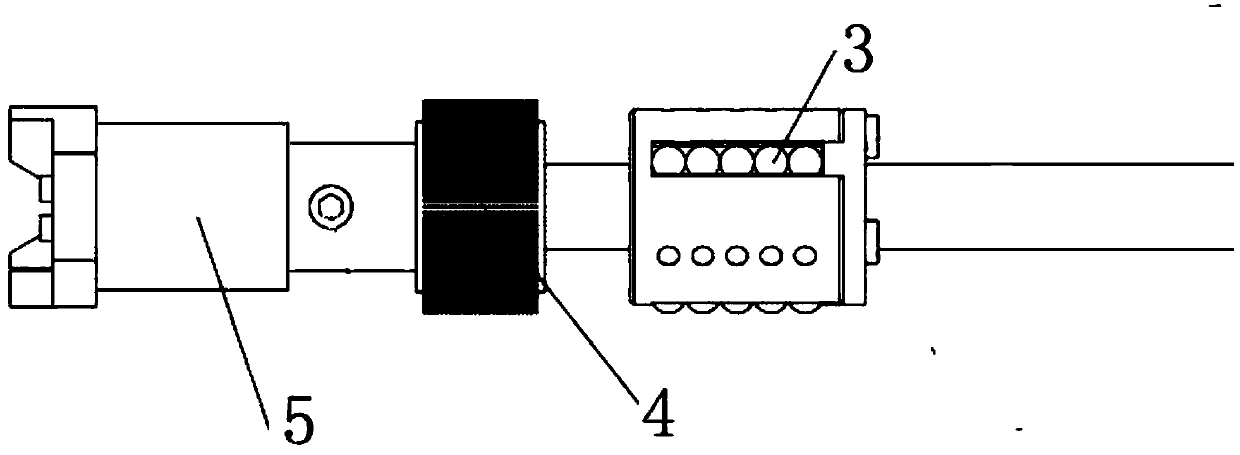

[0022] (1) Collimation correction of the inner surface of the straight pipe; figure 1 Turning tool 5 on the top is realized, turning tool 5 is an ordinary lathe clamped there, and the turning tool made of hard alloy material is used to pre-turn the pipe to adjust its size and alignment. The turning tool 5 can be Do radial fine-tuning.

[0023] (2) Chip removal in alignment correction; by figure 1 The steel brush 4 realizes chip cleaning.

[0024] (3) Point contact produces high-speed shear plastic deformation, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com