Patents

Literature

65results about How to "Reduce carburization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance coatings and surfaces to mitigate corrosion and fouling in fired heater tubes

InactiveUS20100015564A1Reduce carburizationReduced form requirementsMuffle furnacesOther heat production devicesMulliteSpinel

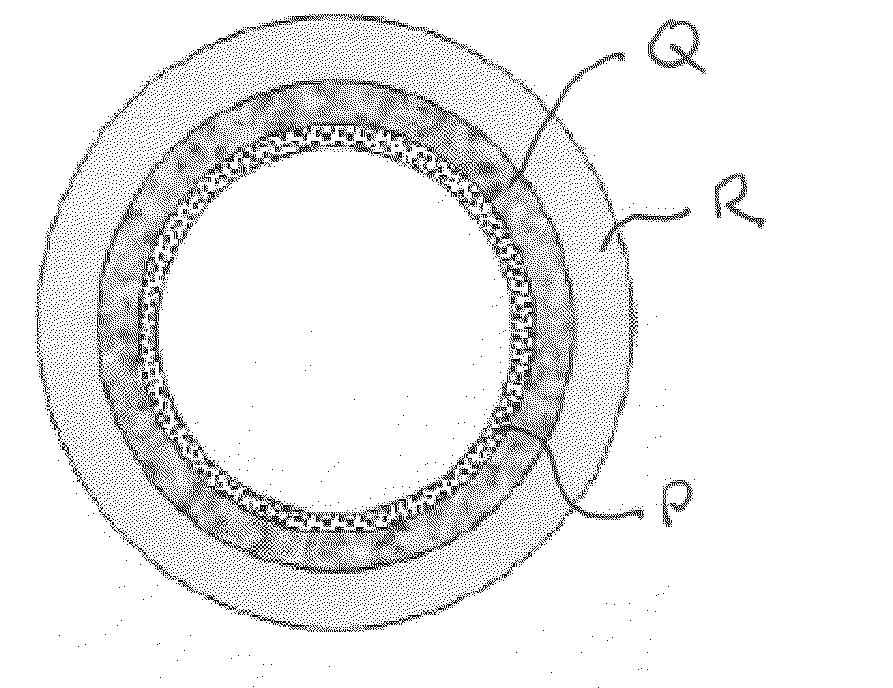

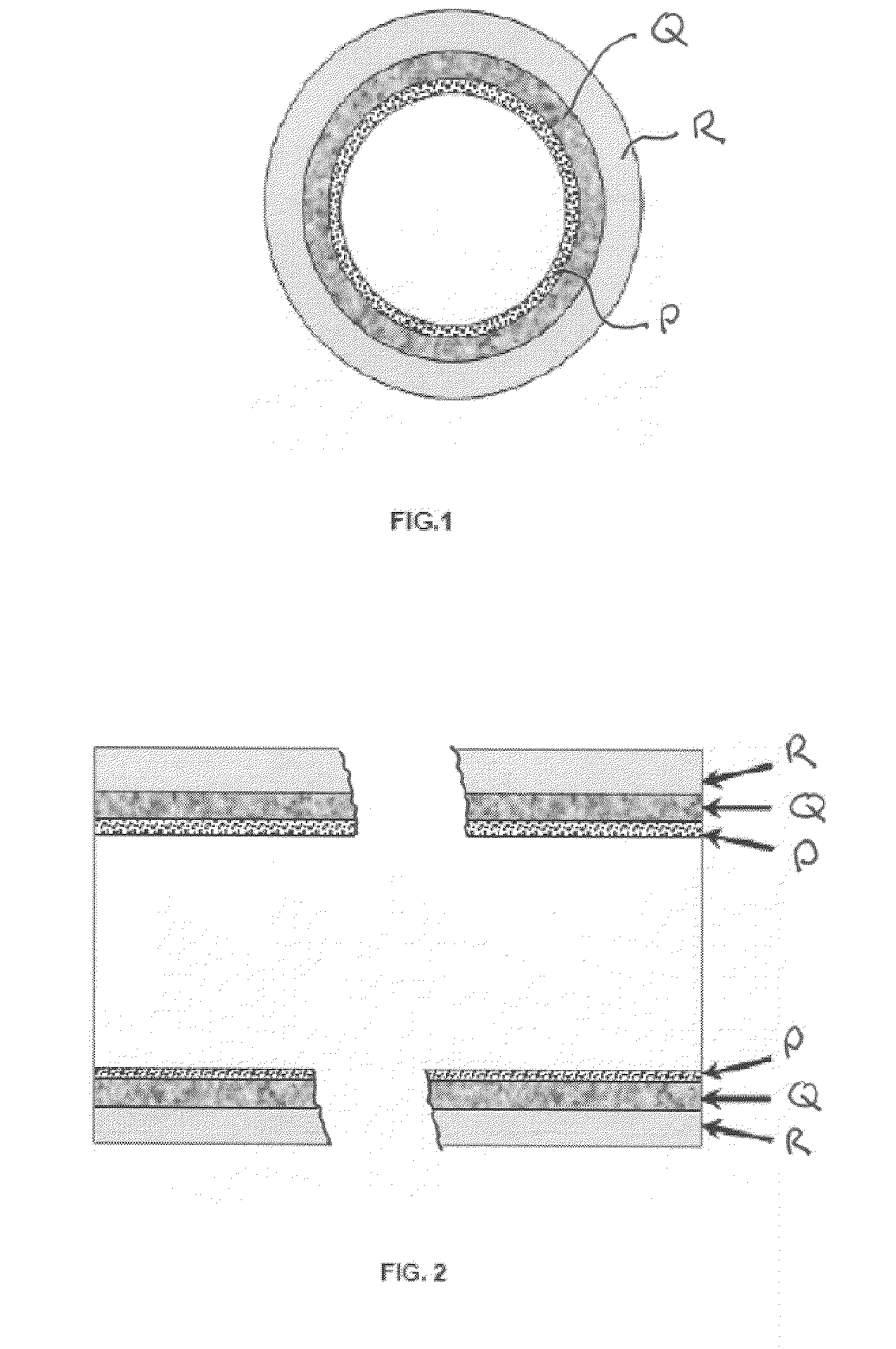

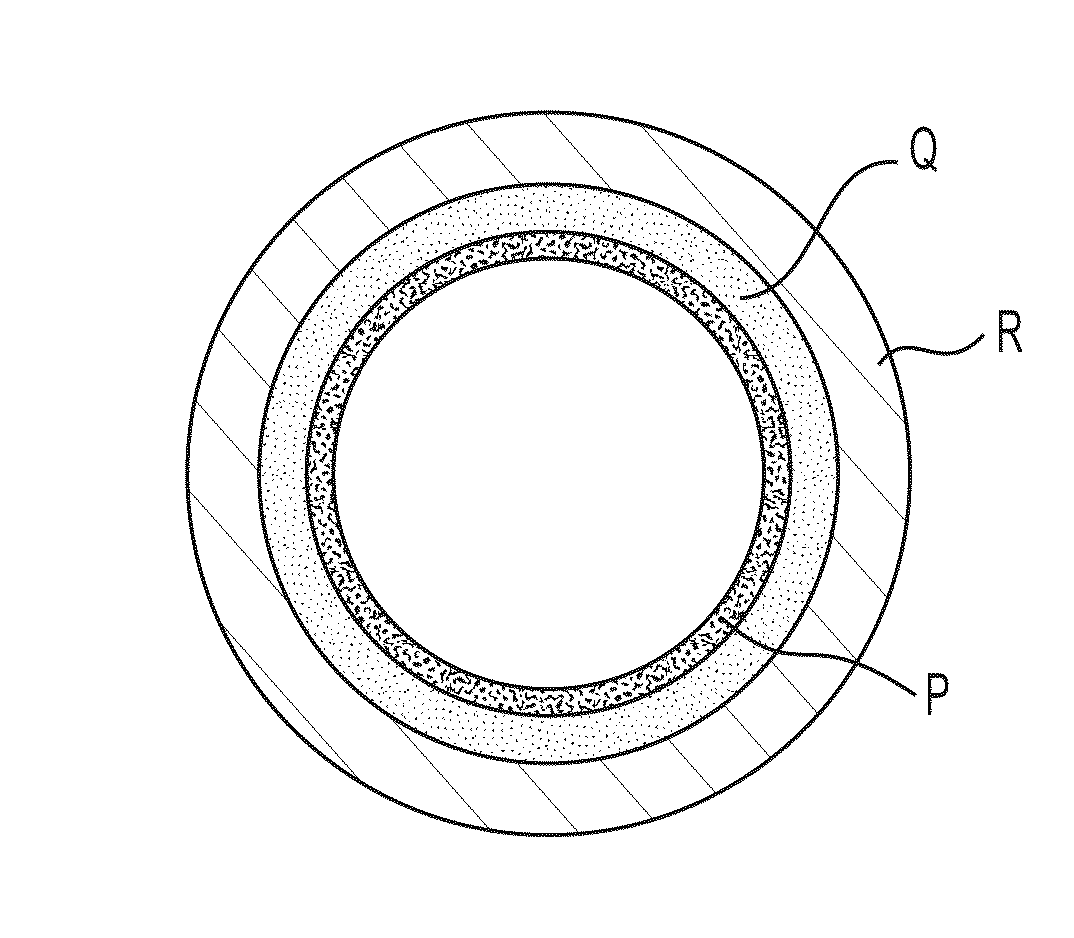

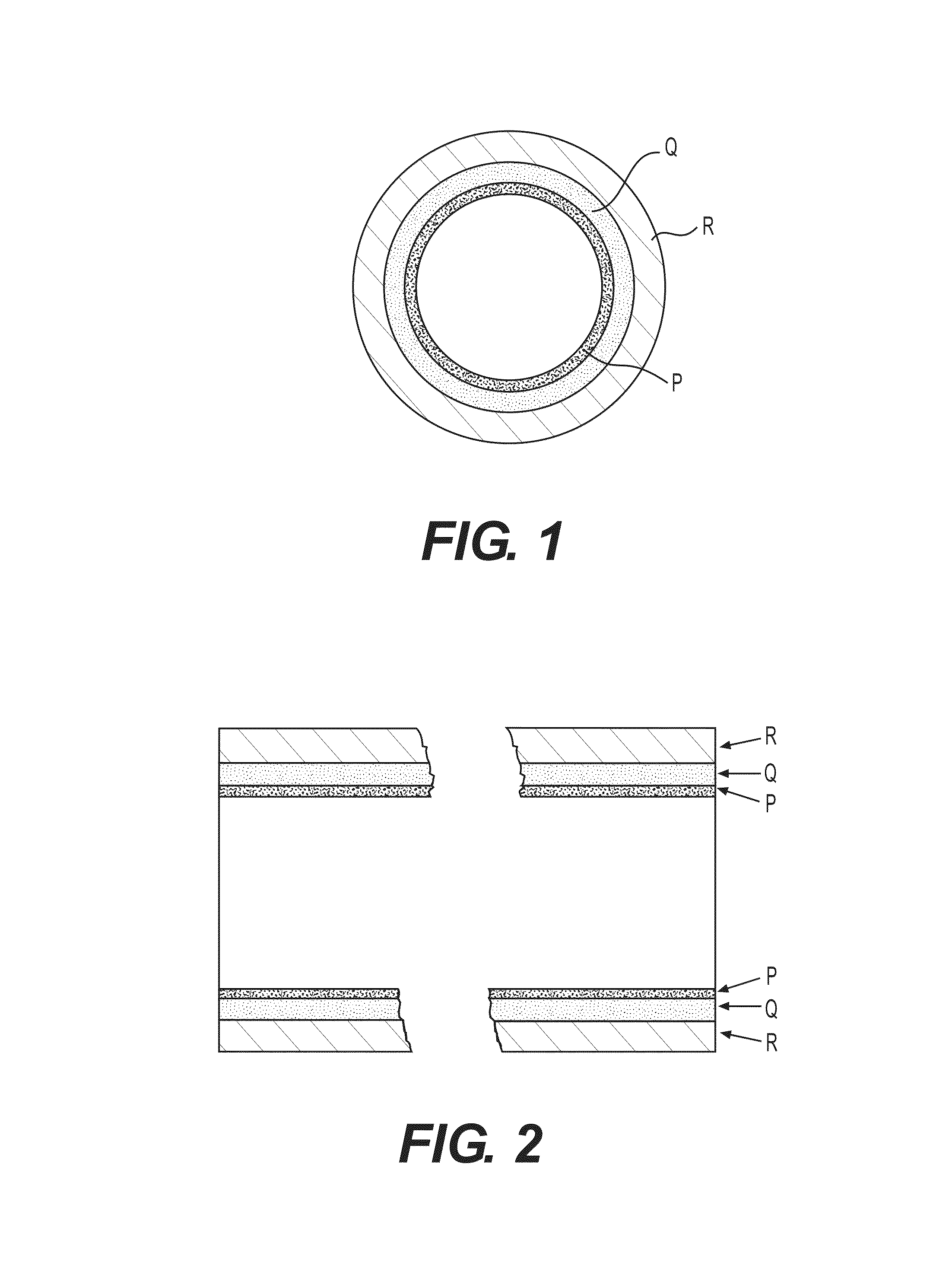

A fired heater tube that is resistant to corrosion and fouling is disclosed. The fired heater tube comprises an advantageous high performance coated material composition resistant to corrosion and fouling comprises: (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal layer, wherein P is substantially comprised of alumina, chromia, silica, mullite, spinels, and mixtures thereof, Q comprises Cr, and at least one element selected from the group consisting of Ni, Al, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Re, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof, and R is selected from the group consisting of low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys.

Owner:EXXON RES & ENG CO

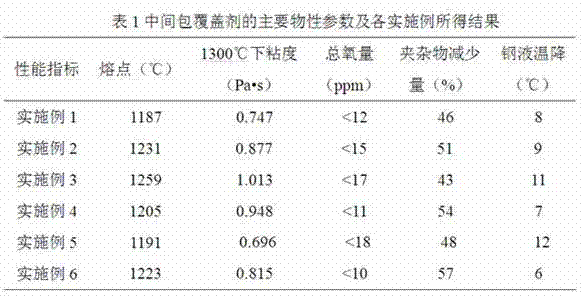

High casting speed continuous casting covering slag used for ultra-low-carbon steel

ActiveCN101530896AAvoid negative effectsReduce carburizationProcess efficiency improvementSteelmakingFire retardant

The invention relates to assistant materials used for continuous casting of steelmaking, in particular to a high casting speed continuous casting covering slag used for ultra-low-carbon steel, comprising pre-melt material and accessory material. The percentage proportion of chemical components of the pre-melt material is as follows: 30 to 40 percent of CaO, 35 to 45 percent of SiO2, 3 to 10 percent of Al2O3, 1 to 5 percent of MgO, 4 to 8 percent of F, 6 to 12 percent of Na2, 0.5 to 3 percent of B2O3, and the rest is micro-impurity contained in the materials. The alkalinity, namely CaO / SiO2, of the pre-melt material is 0.70 to 1.05; the viscosity is 0.2 to 0.5Pa.s; and the pre-melt material is processed by pre-melting. The accessory material comprises 0.7 to 0.9 percent of simple-substance carbon and 0.25 to 1.5 percent of boron flame retardant, wherein a small part of the boron flame retardant is added in the form of borax and the majority of the boron materials is pre-melted into the pre-melt material; and the content of B2O3 in the pre-melted slag is 0.5 to 3 percent. The accessory material also comprises 0.2 to 0.8 percent of CaSi powder and 0.8 to 4.0 percent of manganese minerals. The high casting speed continuous casting covering slag not only can effectively reduce the carburetion of the covering slag to molten steel, but also can avoid negative impact on the metallurgical physicochemical property of the covering slag.

Owner:BAOSHAN IRON & STEEL CO LTD

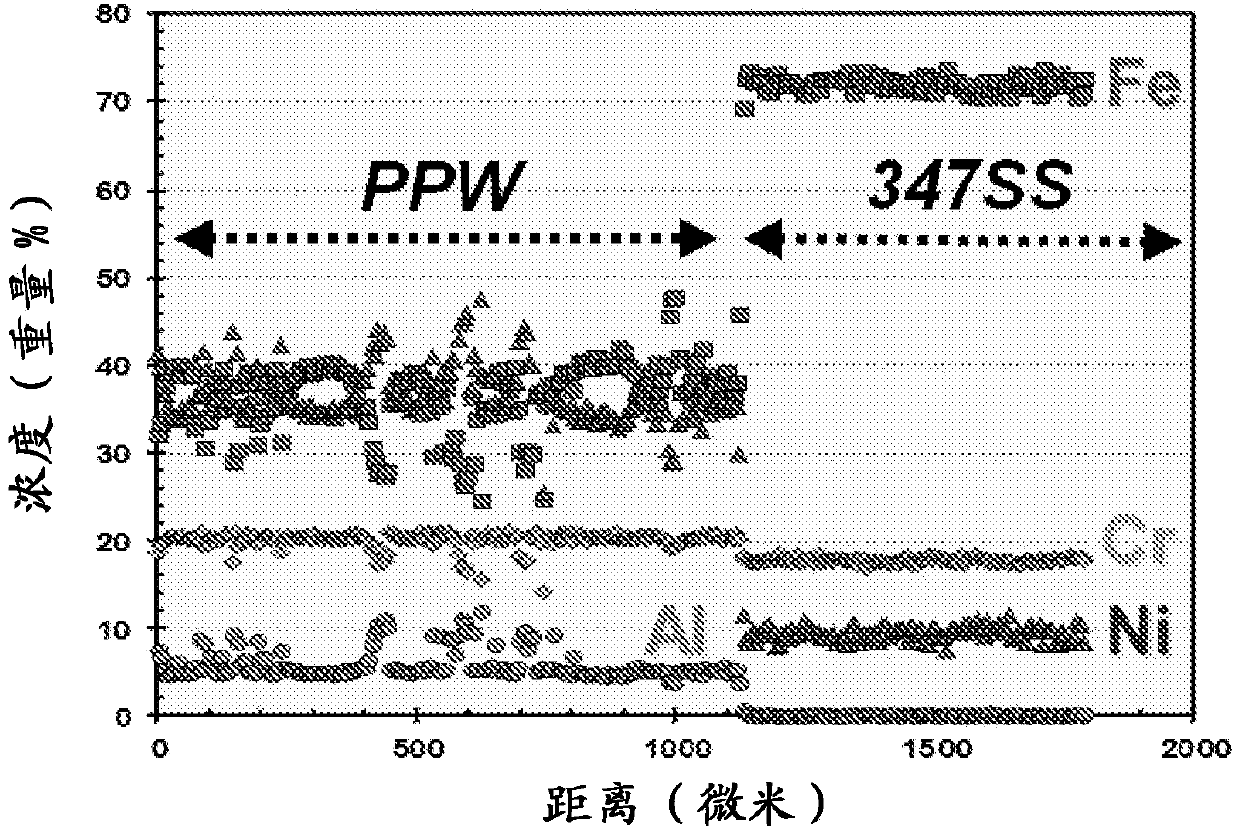

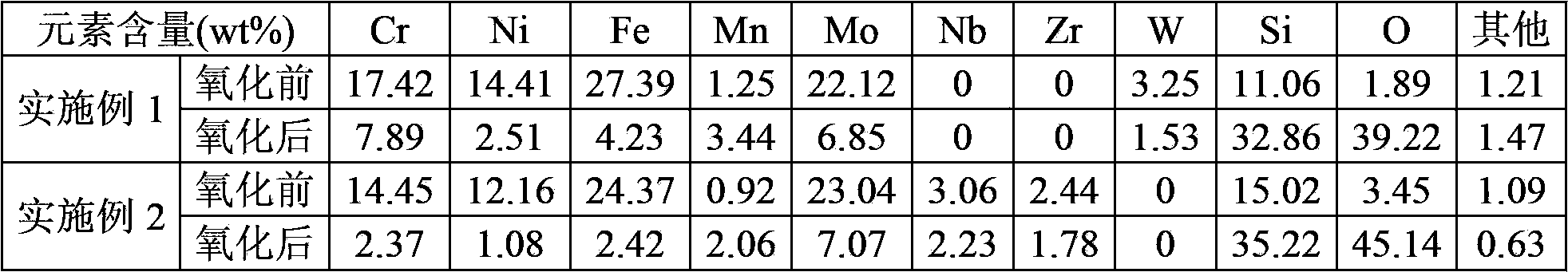

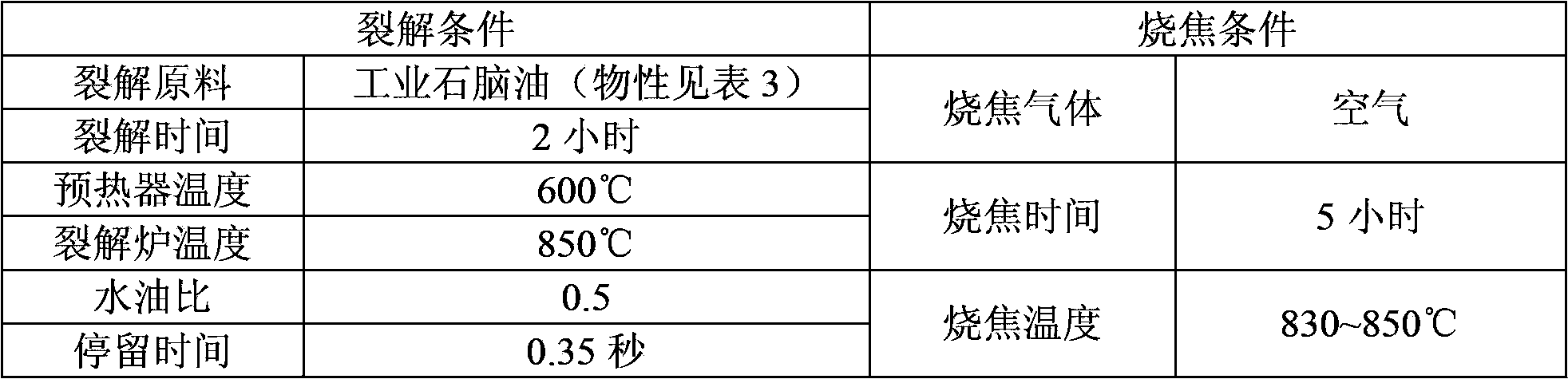

Cracking furnace tube for retarding coking and carburizing of ethylene cracking furnace tube, and manufacturing method thereof

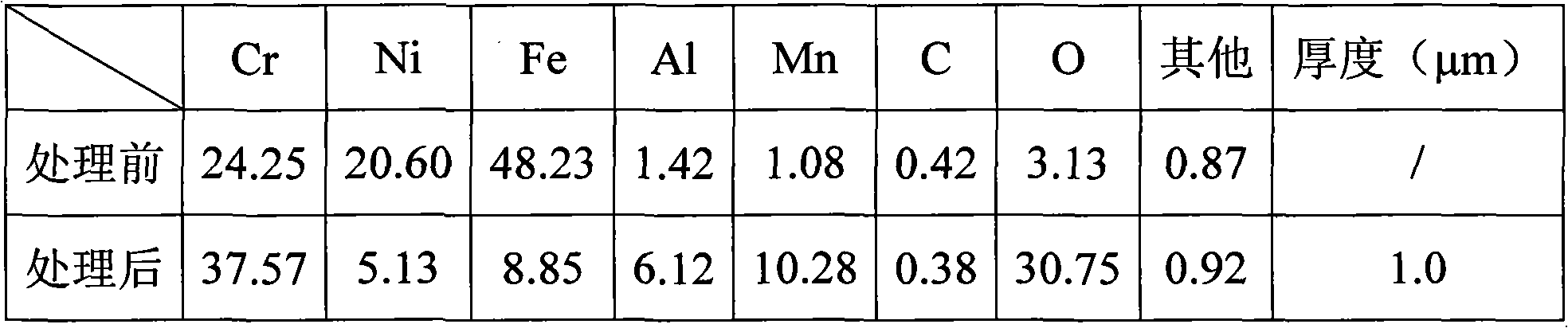

ActiveCN102399571AInhibit cokingInhibition of carburizationThermal non-catalytic crackingCarbon numberPetroleum

The present invention relates to a cracking furnace tube for retarding coking and carburizing of an ethylene cracking furnace tube, and a manufacturing method thereof. According to the present invention, the inner surface of the cracking furnace tube is provided with a layer of an oxide film, wherein the oxide film comprises at least one element selected from Cr, Ni, Fe, Mn, Al, Si and B; the manufacturing method comprises: directly adding at least one element selected from Al, Si or B to a nickel-chromium alloy containing elements of Cr, Ni, Fe, Mn and C during the conventional cracking furnace tube manufacturing process to prepare the tube, then carrying out a heat treatment for the resulting tube under low oxygen partial pressure atmosphere to generate a layer of the metal and / or nonmetal oxide thin film on the inner surface of the tube; when the cracking furnace tube of the present invention is adopted for producing olefin with low carbon number by the petroleum hydrocarbon cracking furnace, the deposition of the coke on the inner wall of the furnace tube can be reduced by more than 70%.

Owner:CHINA PETROLEUM & CHEM CORP +2

Periclase-silicon carbide-carbon composite materials and method for preparing same

InactiveCN1884202AHigh melting pointHigh thermal conductivityCarbon compositesHexamethylenetetramine

The invention discloses a periclase-carborundum-carbon composite material and preparing method, which comprises the following steps: blending 60-90% electric melting or sintered magnesite, 5-35% carborundum, 2-15 % graphite, 0.5-5% carbon black and 0.5-6% additive; mixing 3-9% binder and 0-1%hexamethylenetetramine hardener; stirring; moulding; baking at 150-350 deg.c for 2-24 h. The invention improves oxidation resistance of material and penetrability and aggressivity resistance of melting waste and metal fusion, which fits melting furnace and container liner widely.

Owner:WUHAN UNIV OF SCI & TECH

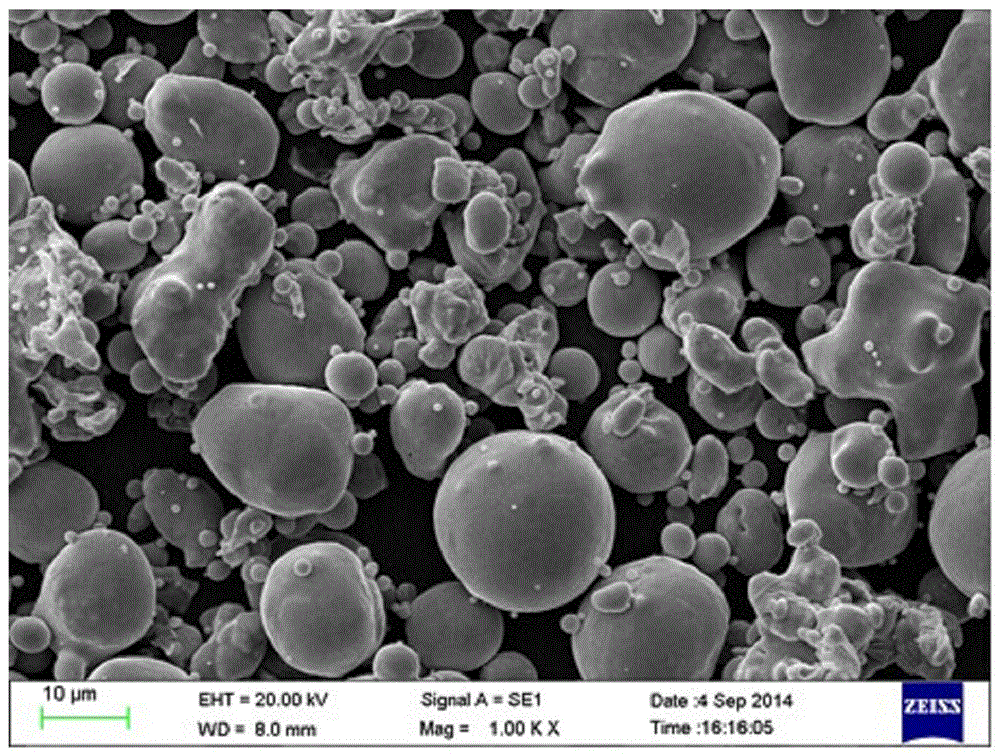

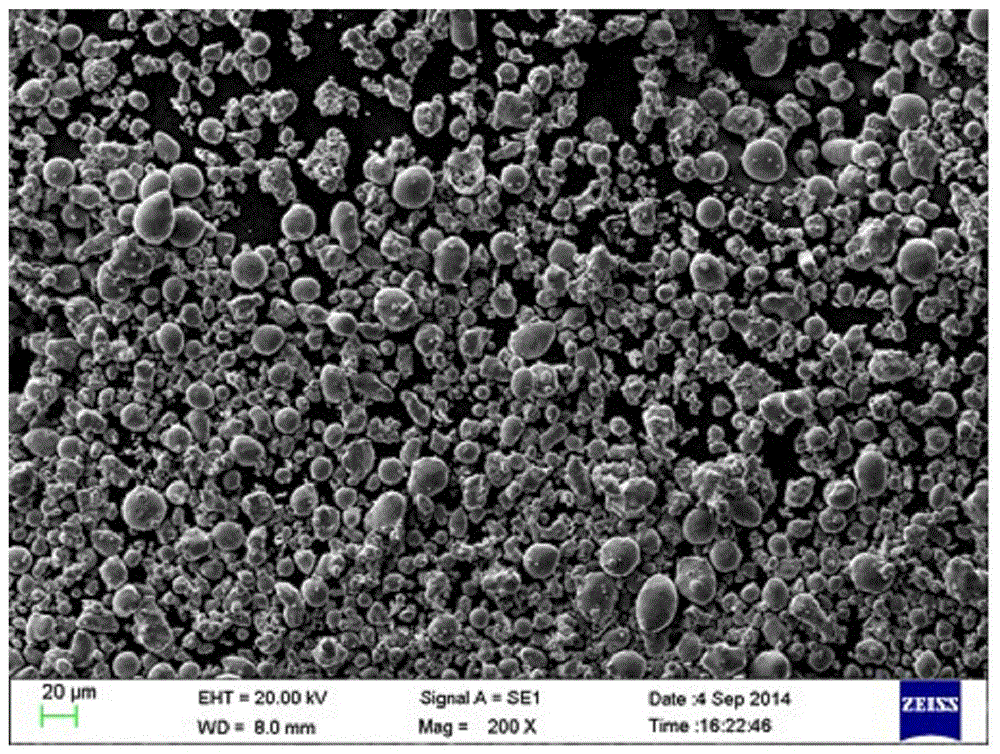

Powder catalyst for synthesizing ultrafine granular diamond

ActiveCN104226355AImprove crystal qualityLower melting temperaturePhysical/chemical process catalystsUltra-high pressure processesSingle crystalMaterials science

The invention discloses a powder catalyst for synthesizing ultrafine granular diamond. The powder catalyst is mainly prepared from the following alloying components by weight percent: 20% to 25% of Fe, 3% to 5% of Co, 0.5% to 2% of Ce, 3% to 5% of Mn, 0.5% to 1% of SiC, 0.5% to 1% of Mo and the balance being Ni. By utilizing the technical scheme of the powder catalyst, the high-purity ultrafine-particle spherical or approximately spherical powder catalyst can be prepared, and the granularity of the obtained powder catalyst is 600 to 1000 meshes. When the powder catalyst is applied to synthesis of ultrafine diamond single crystal, single-crystal diamonds within 400 meshes can be produced.

Owner:HENAN POWER NEW MATERIAL

Tundish covering agent for continuous casting of low-carbon steel containing Al and Ti and application thereof

InactiveCN105436447AContinuous casting production went smoothlyEffective absorptionAlkalinityThermal insulation

The invention provides a tundish covering agent for continuous casting of low-carbon steel containing Al and Ti and an application thereof. The tundish covering agent is prepared from, by mass, 32%-43% of CaO, 7%-14% of SiO2, 25%-32% of Al2O3, 6%-14% of MgO, 6%-13% of (Na2O+Li2O), 3%-7% of B2O3, 0.5%-1.5% of C and 1.1%-2% of TiO2. The tundish covering agent is low in melting temperature and viscosity and high in alkalinity. The tundish covering agent has the advantages that the tundish covering agent is suitable for continuous casting of the low-carbon steel containing Al and Ti, the mass percentage of C is smaller than or equal to 0.1%, the content of Al is smaller than or equal to 0.5%, and the content of Ti is smaller than or equal to 0.5%, inclusions in the low-carbon steel containing Al and Ti can be efficiently absorbed, the cleanliness of molten steel in a tundish is increased, secondary oxidation of the molten steel is well avoided, recarburization is avoided, the quality of a casting blank is improved, and meanwhile good thermal insulation performance is achieved.

Owner:CENT SOUTH UNIV

Austenitic stainless steel, application thereof and surfacing process

InactiveCN107217215AReduce carburizationAvoid intergranular corrosion problemsGas flame welding apparatusNitrogenMechanical property

The invention discloses austenitic stainless steel and its application and surfacing welding process. The austenitic stainless steel is calculated by weight percentage, C: ≤0.1%, Ni: 16%-24%, Cr: 20%-28%, Nb Or Ti: ≤1.0%. The austenitic stainless steel described in the present invention is a new type of corrosion-resistant austenitic stainless steel suitable for oxyacetylene flame surfacing welding, which is developed according to the structural characteristics of hook claws and connecting rods, the special oxyacetylene welding method and the oxyacetylene welding process. Stainless steel, the new austenitic stainless steel is not only basically consistent with the existing Z2CN19-10 nitrogen control and Z6CNNb18-11 in terms of mechanical properties, but also can effectively reduce the carburization of the substrate during oxyacetylene flame surfacing, thereby effectively It is of great practical value to avoid the intergranular corrosion problem of the oxyacetylene welded claw parts.

Owner:SICHUAN HUADU NUCLEAR EQUIP MFR

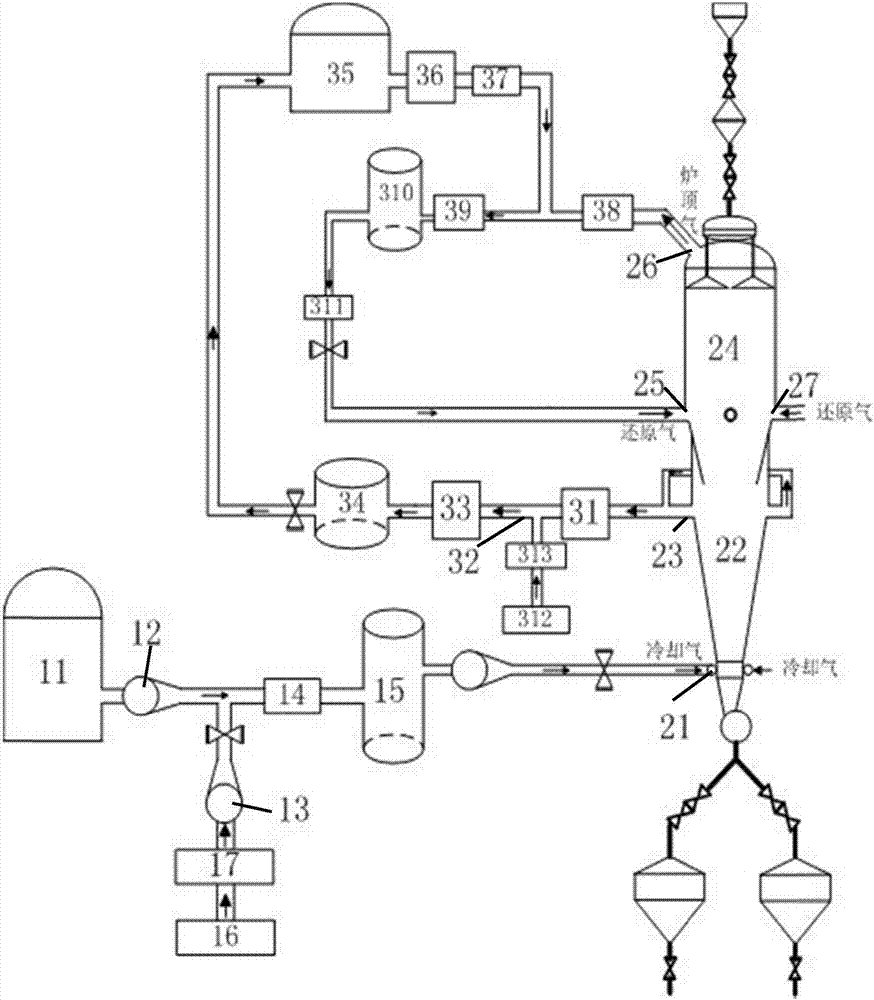

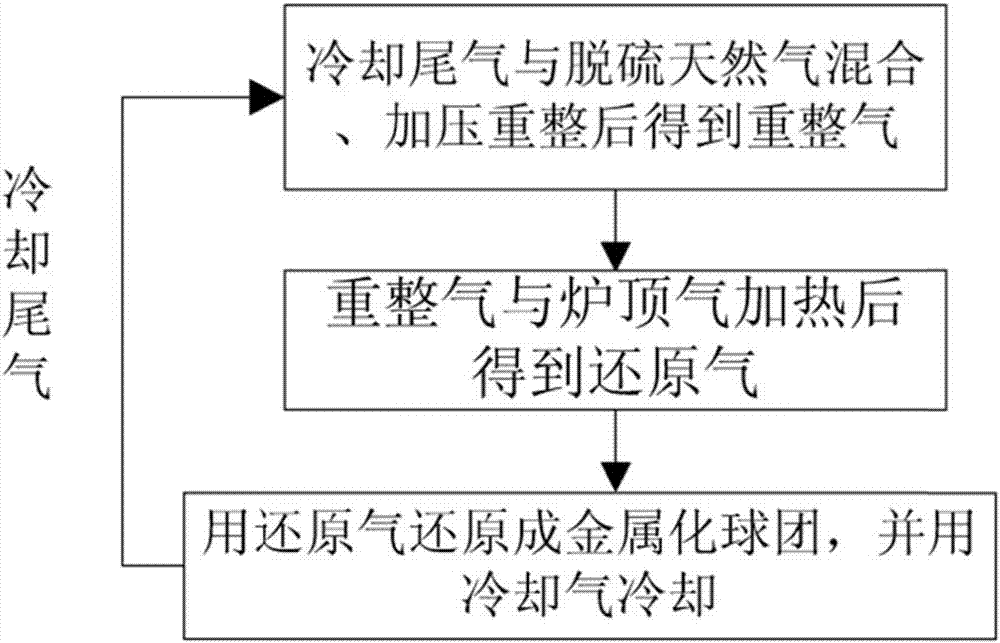

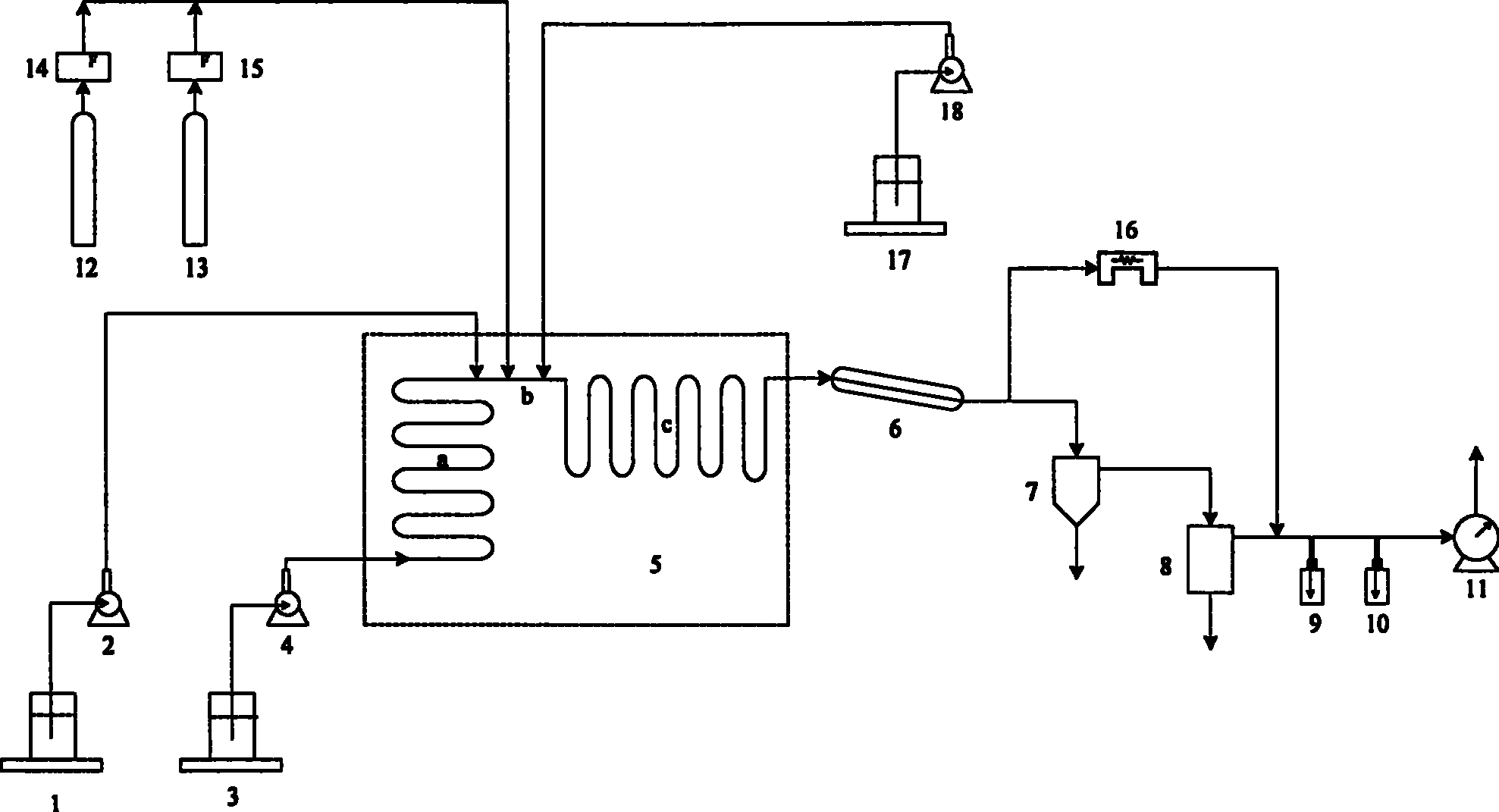

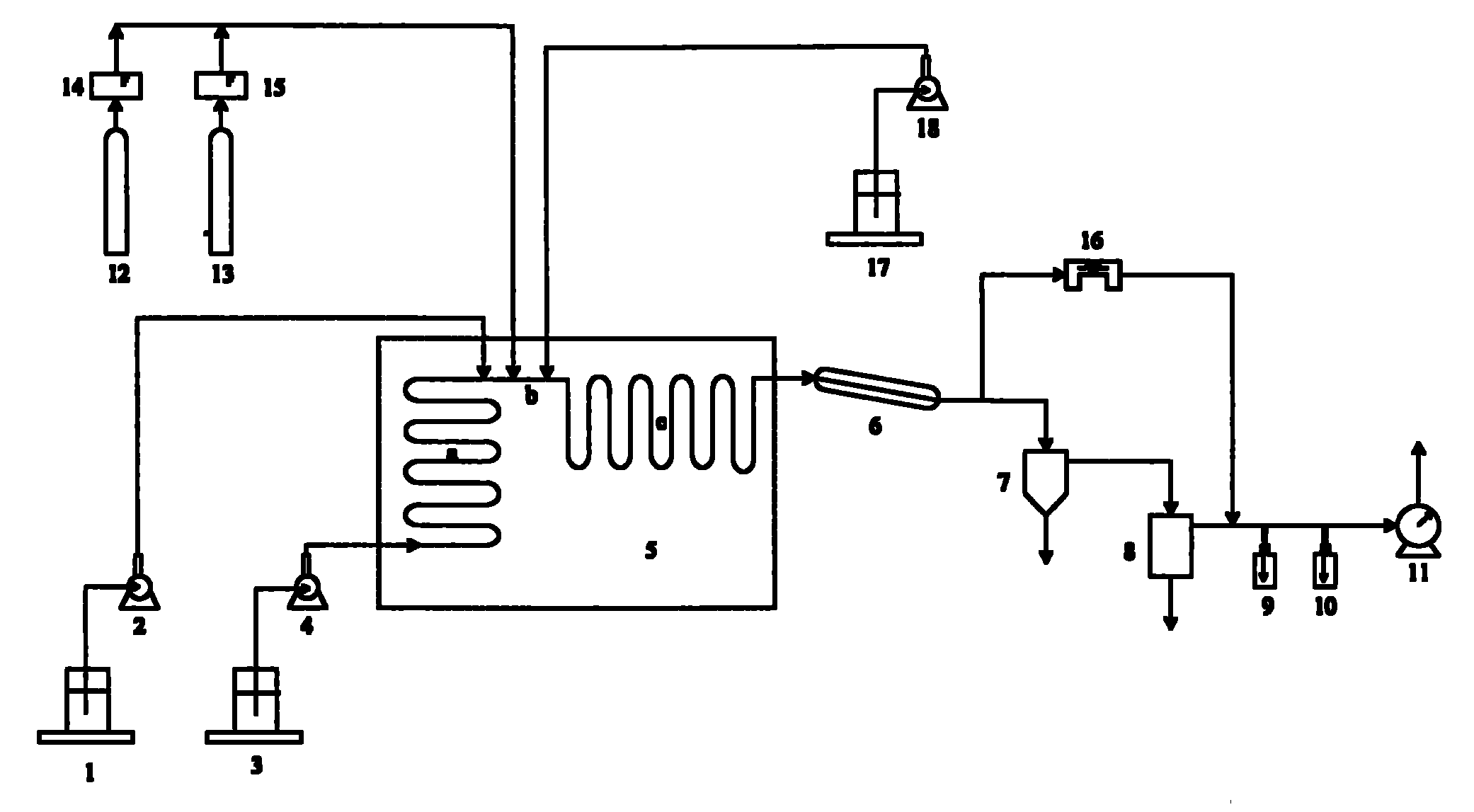

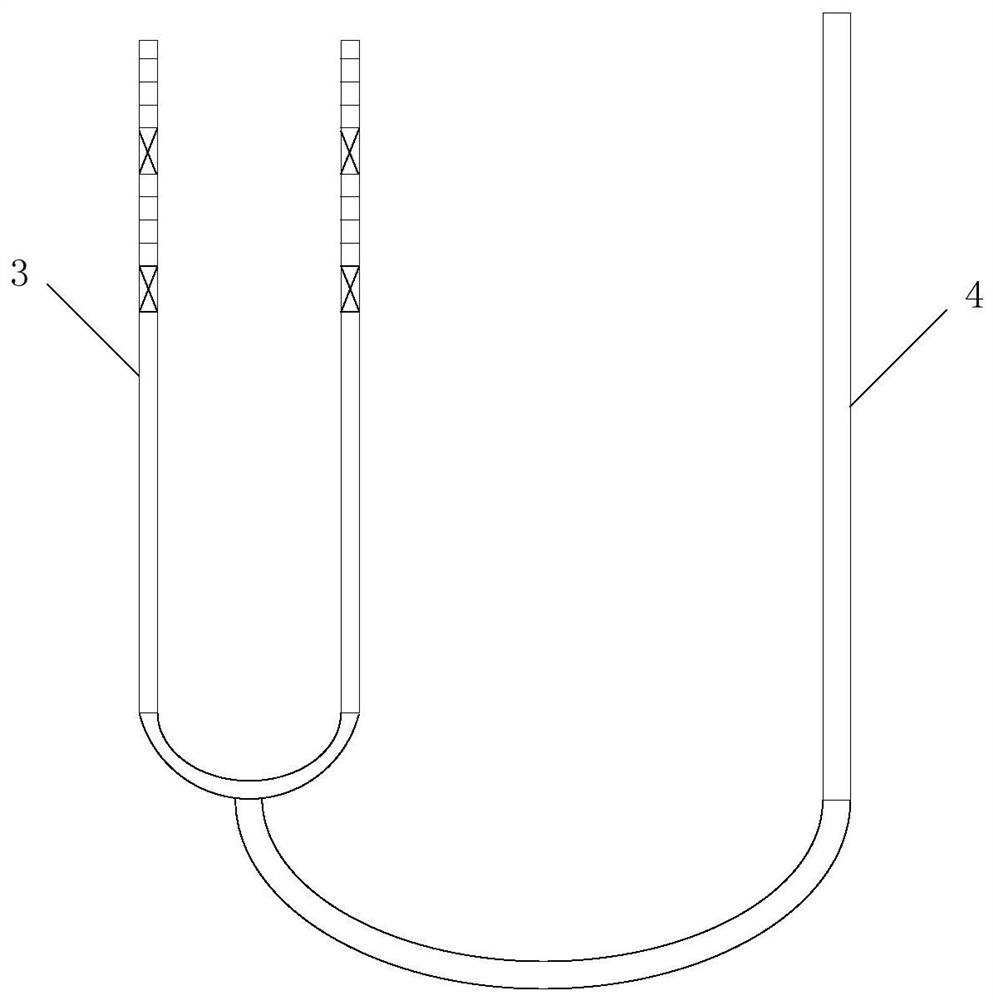

System and method for reducing and cooling metallized pellets

The invention relates to a gas-based shaft furnace reducing system. The system comprises a gas-based shaft furnace, a cooling gas supply system and a reducing gas supply system, wherein the cooling gas supply system is used for preparing water vapor and desulfurated natural gas into cooling gas with main components of methane and water, and conveying the cooling gas to the gas-based shaft furnace;and the reducing gas supply system is used for treating cooling tail gas used by the gas-based shaft furnace to obtain reducing gas with carbon monoxide and hydrogen gas as main components, and conveying reducing gas to the gas-based shaft furnace. The invention further relates to a method for reducing and cooling metallized pellets. According to the system and the method disclosed by the invention, methane and water vapor in cooling gas have reforming reaction to generate CO and H2 under catalytic action of hot-stated metallized pellets (also can be ferrugination pellets), the reaction is remarkable in heat absorbing effect, retention time, at a cooling section of the gas-based shaft furnace, of the metallized pellets is remarkably shortened, dosage of cooling gas is also remarkably reduced, and compaction and production efficiency improvement of a shaft furnace body are facilitated.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

High casting speed continuous casting covering slag used for ultra-low-carbon steel

ActiveCN101530896BAvoid negative effectsReduce carburizationProcess efficiency improvementSteelmakingFire retardant

The invention relates to assistant materials used for continuous casting of steelmaking, in particular to a high speed continuous casting mold flux used for ultra-low-carbon steel, comprising a premelting material and an accessory material. The percentage proportion of chemical components of the premelting material is as follows: 30 to 40 percent of CaO, 35 to 45 percent of SiO2, 3 to 10 percent of Al2O3, 1 to 5 percent of MgO, 4 to 8 percent of F, 6 to 12 percent of Na2, 0.5 to 3 percent of B2O3, and the balance being microimpurity contained in raw materials. The alkalinity, namely CaO / SiO2, of the premelting material is 0.70 to 1.05; the viscosity is 0.2 to 0.5Pa.s; and the premelting material is processed by pre-melting. The accessory material comprises 0.7 to 0.9 percent of simple-substance carbon and 0.25 to 1.5 percent of boron flame retardant, wherein a small part of the boron flame retardant is added in the form of borax and the majority of the boron materials is pre-melted into the premelting material; and the content of B2O3 in the pre-melted slag is 0.5 to 3 percent. The accessory material also comprises 0.2 to 0.8 percent of CaSi powder and 0.8 to 4.0 percent of manganese ore. The high speed continuous casting mold flux not only can effectively reduce the carburetion of the mold flux to molten steel, but also can avoid negative impact on the metallurgical physicochemical property of the mold flux.

Owner:BAOSHAN IRON & STEEL CO LTD

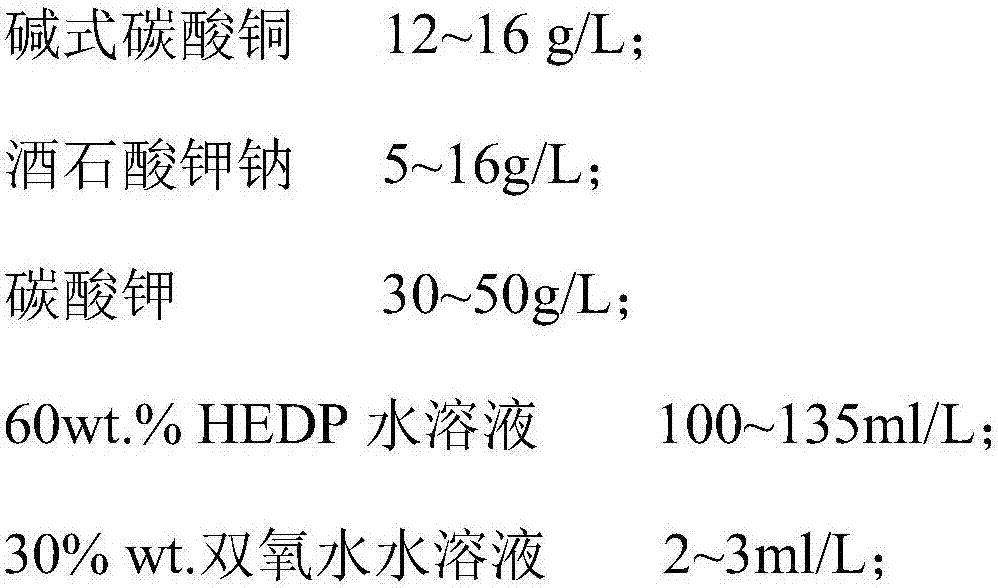

Preparation method of HEDP copper-plated non-porous thin layer

The invention belongs to the technical field of cyanide-free copper plating technology, and particularly relates to a preparation method of an HEDP copper-plated non-porous thin layer. The preparation method comprises the steps that abrasive paper is used for polishing to remove floating rust at first, then, chemical degreasing and activation are carried out, and finally deionized water is used for cleaning; a plating solution is prepared; plating is carried out, particularly, an electrolysis copper plate is used as an anode, an oxidation film on the surface of the copper plate is removed, activation treatment is carried out for 5-10 s through a 10%-20% dilute hydrochloric acid solution, a base plate which is treated is used as a cathode to be placed in the plating solution, the temperature is 50-65 DEG C, the pH value is 9-11, direct current plating is carried out, the current density is 0.5-3.5 A / dm<2>, plating is carried out under the cathode moving condition, the moving speed is 3 cm / s-5 cm / s, and the HEDP copper-plated non-porous thin layer is obtained. The HEDP alkaline plating solution is low in toxicity, environmentally friendly and quite low in corrosion to production equipment, the leveling ability, dispersing ability and deep plating ability of the HEDP alkaline plating solution can reach or even exceed those of a cyanide copper plating solution, the cathode current efficiency reaches up to 95% or above, and the plating solution is stable in performance.

Owner:SHENYANG AIRCRAFT CORP

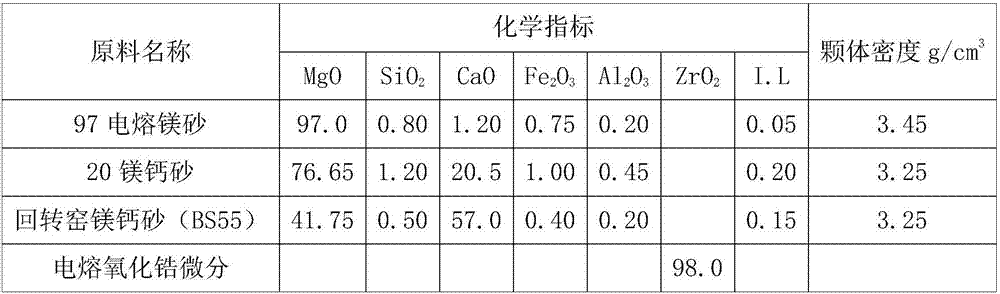

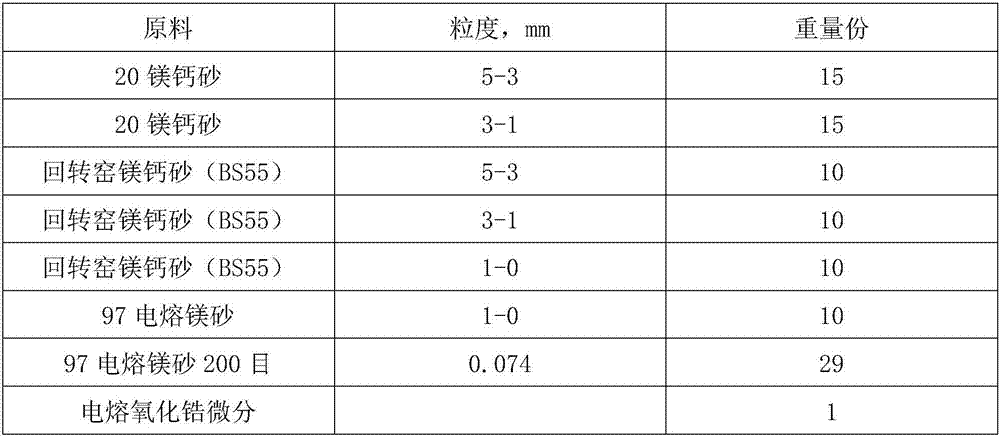

Unburned magnesium-calcium zirconate brick not containing free carbon

The invention relates to an unburned magnesium-calcium zirconate brick not containing free carbon. The unburned magnesium-calcium zirconate brick comprises the following raw materials in parts by weight: 10-20 parts of 97 fused magnesite with the granularity of more than 0 and less than or equal to 1 mm (0-1 mm), 25-35 parts of 200-mesh 97 fused magnesite fine powder, 10-20 parts of 20 calcium magnesium sand with the granularity of more than 1 mm and less than or equal to 3 mm (1-3 mm), 10-15 parts of 20 calcium magnesium sand with the granularity of more than 3 mm and less than or equal to 5 mm (3-5 mm), 5-15 parts of rotary kiln calcium magnesium sand with the granularity of more than 0 and less than or equal to 1 mm (0-1 mm), 5-15 parts of rotary kiln calcium magnesium sand with the granularity of more than 1 mm and less than or equal to 3 mm (1-3 mm), 5-15 parts of rotary kiln calcium magnesium sand with the granularity of more than 3 mm and less than or equal to 5 mm (3-5 mm), 0-3 parts of fused zirconia micro-powder, 0-2 parts of high-temperature asphalt powder and 2-4 parts of a binder. Two calcium magnesium sands with different heat expansion coefficient high-temperature properties are compounded to facilitate prolonging the service life of a refractory material. No graphite is not added, and no free carbon is contained, so that carburetion to molten steel is minimized.

Owner:海城利尔麦格西塔材料有限公司

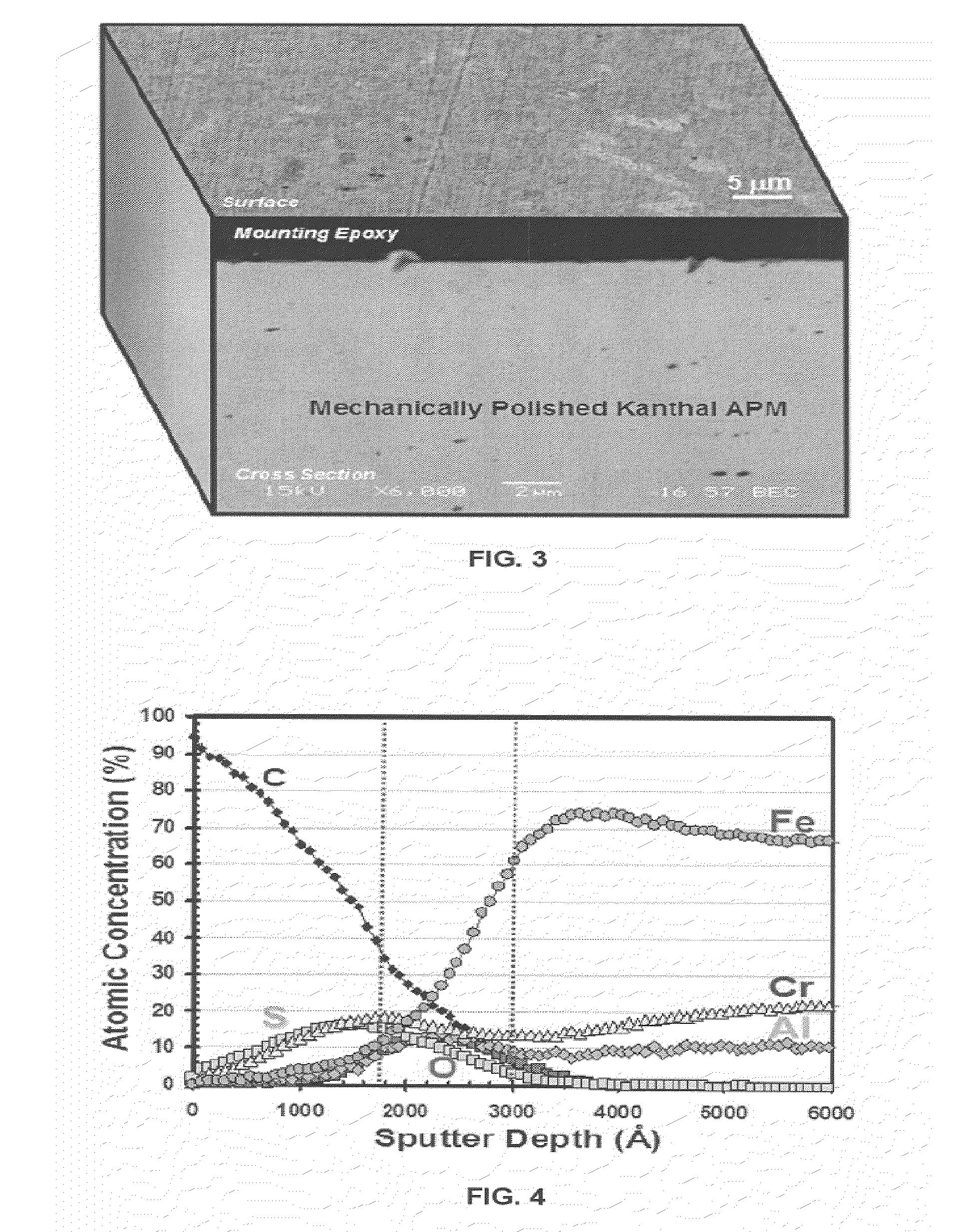

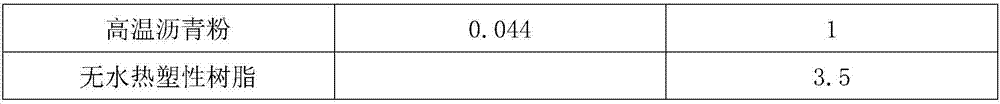

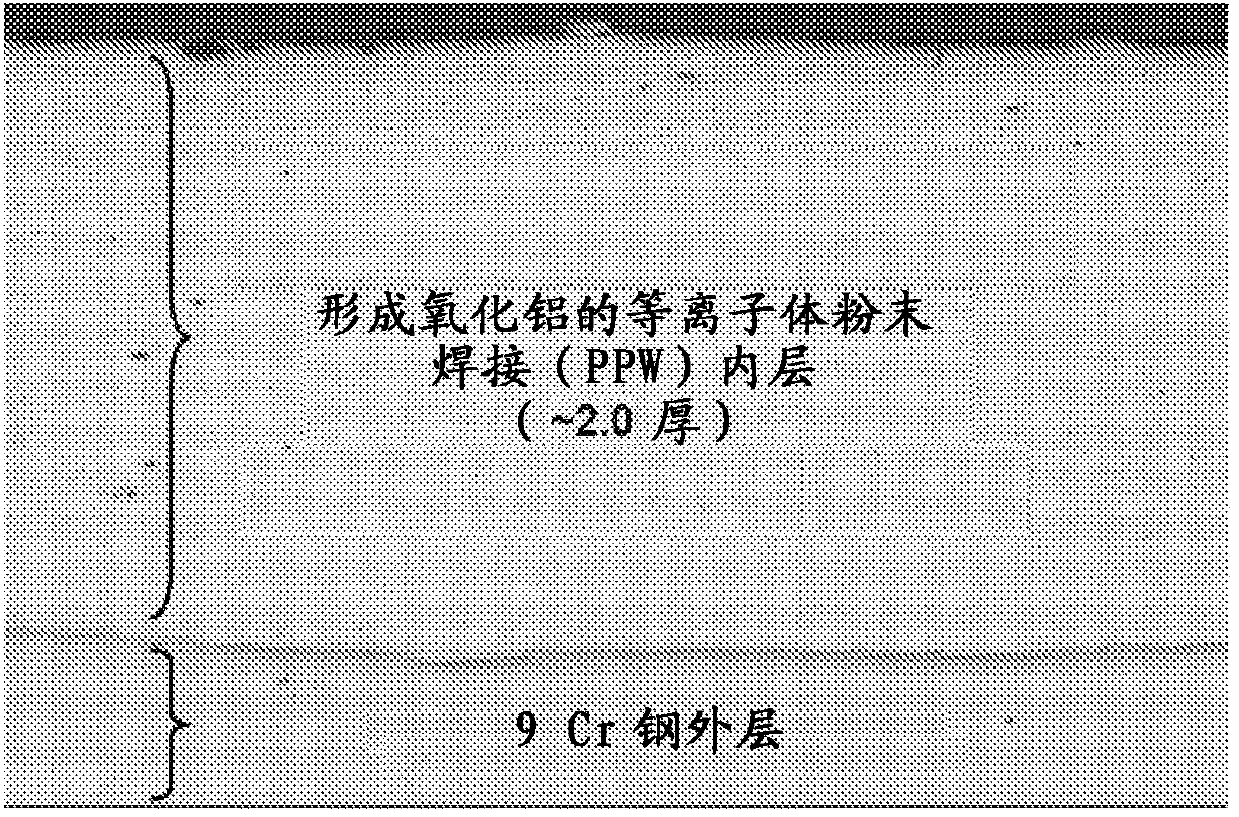

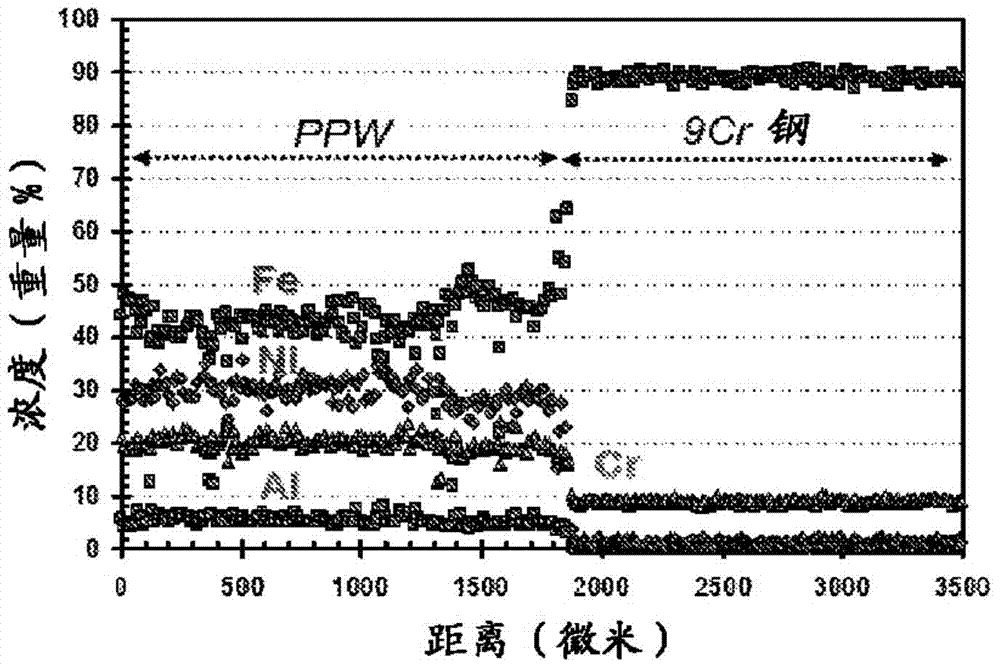

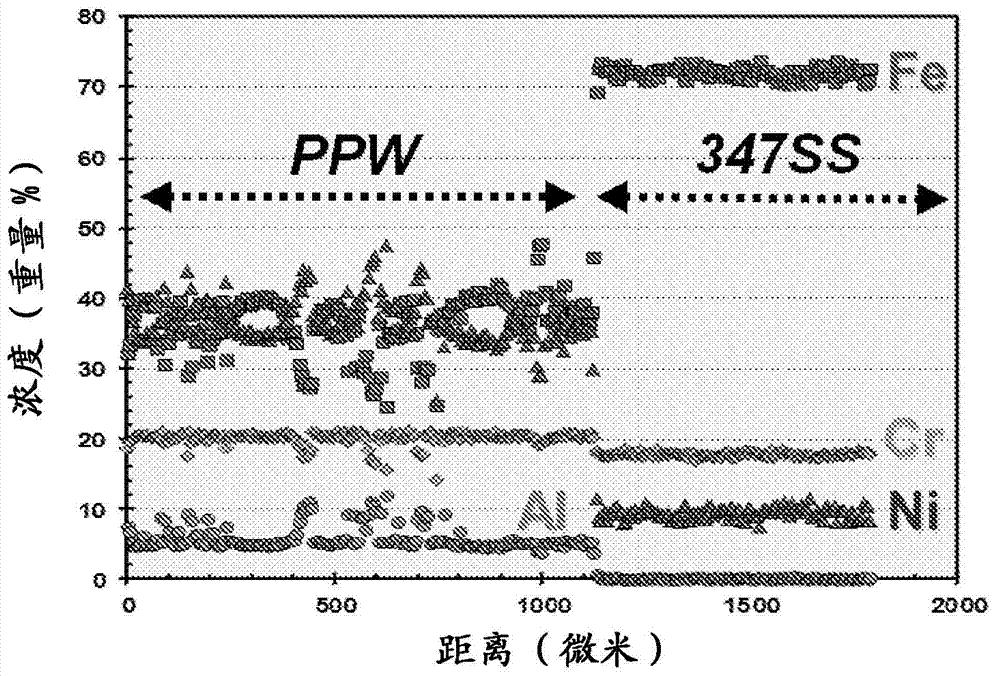

Alumina forming bimetallic tube for refinery process furnaces and method of making and using

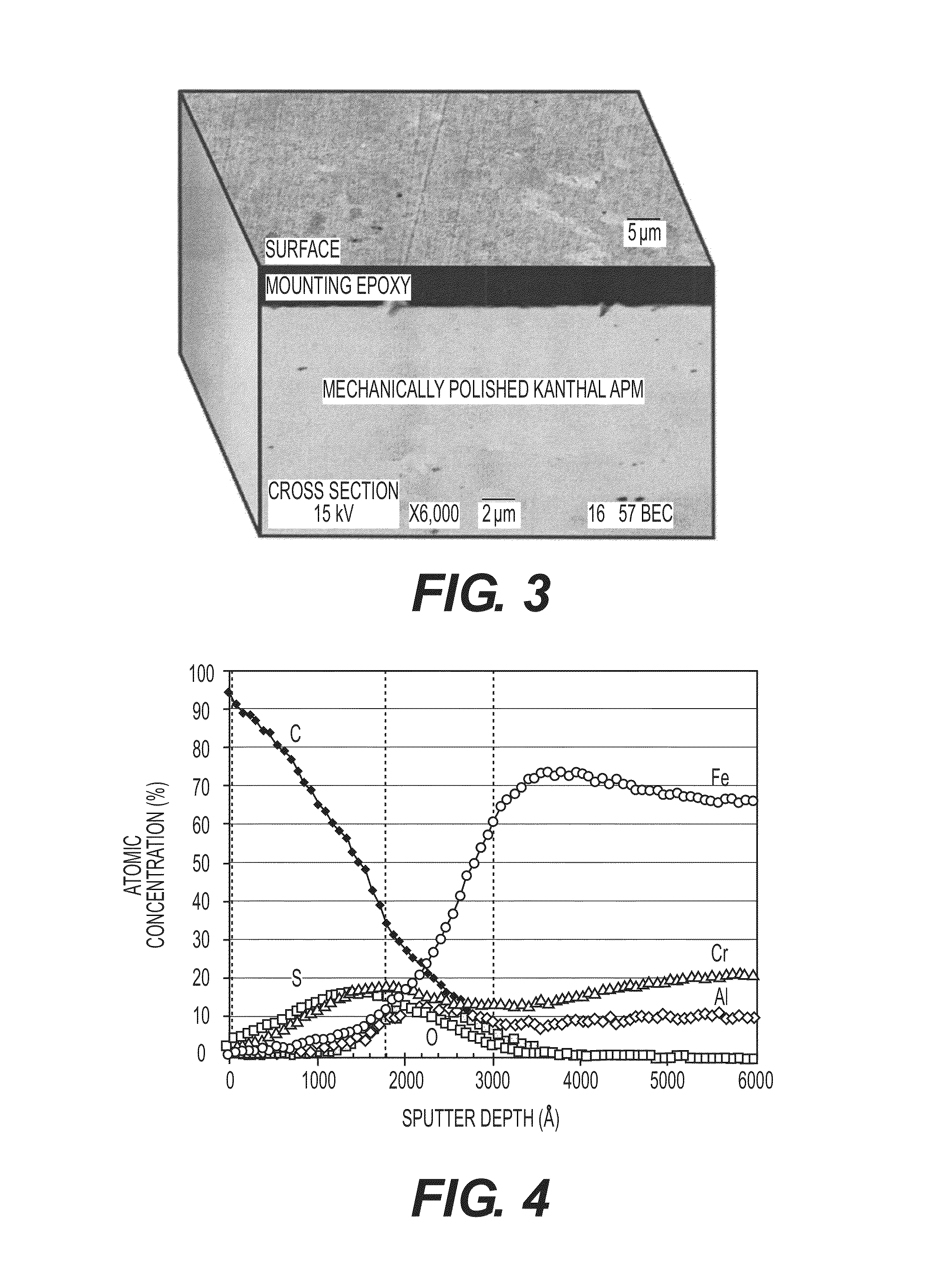

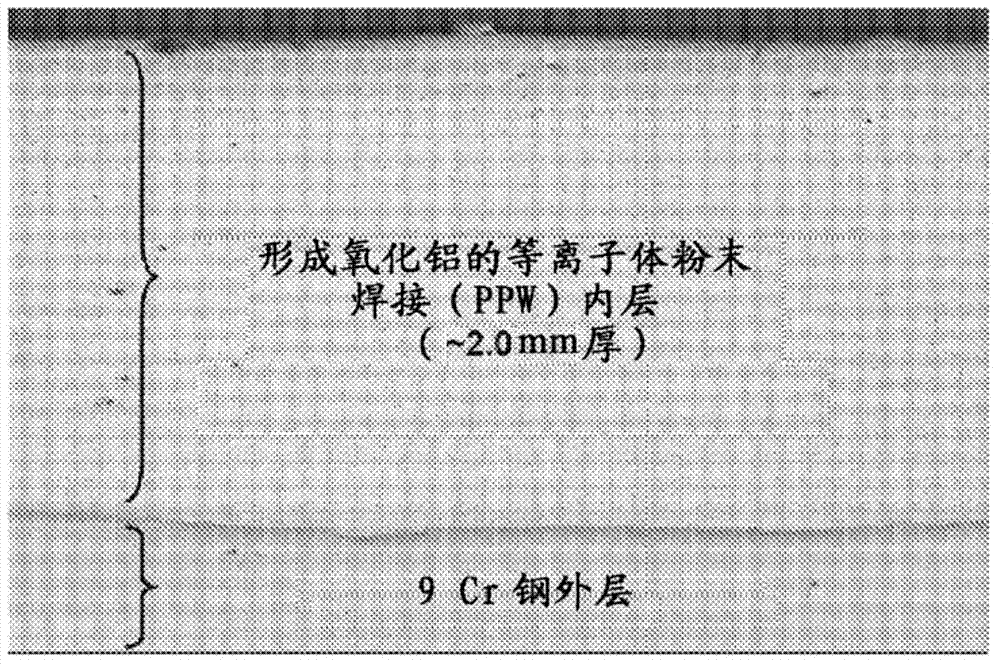

InactiveCN103857971AReduce corrosionReduce foulingThermal non-catalytic crackingMuffle furnacesMulliteSpinel

Provided is a bimetallic tube for transport of hydrocarbon feedstocks in refinery process furnaces, and more particularly in furnace radiant coils, including: i) an outer tube layer being formed from stainless steels including chromium in the range of 15.0 to 26.0 wt.% based on the total weight of the stainless steel; ii) an inner tube layer being formed from an alumina forming bulk alloy including 5.0 to 10.0 wt.% of AL 20.0 wt.% to 25.0 wt.% Cr, less than 0.4 wt.% Si, and at least 35.0 wt.% Fe with the balance being Ni, wherein the inner tube layer is formed plasma powder welding the alumina forming bulk alloy on the inner surface of the outer tube layer; and iii) an oxide layer formed on the surface of the inner tube layer, wherein the oxide layer is substantially comprised of alumina, chromia, silica, mullite, spinels, or mixtures thereof. Also provided are methods of making and using the bimetallic tube.

Owner:EXXON RES & ENG CO

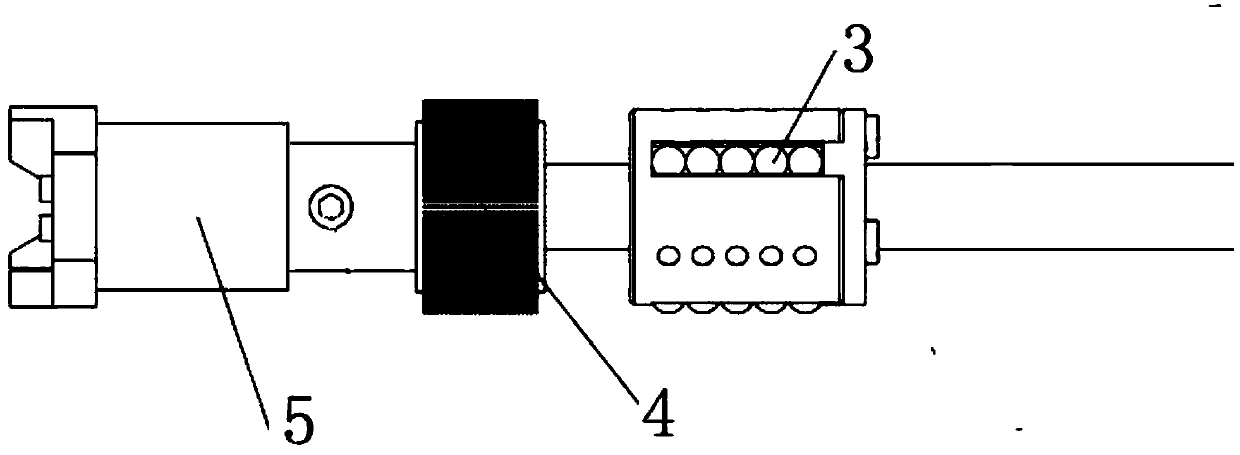

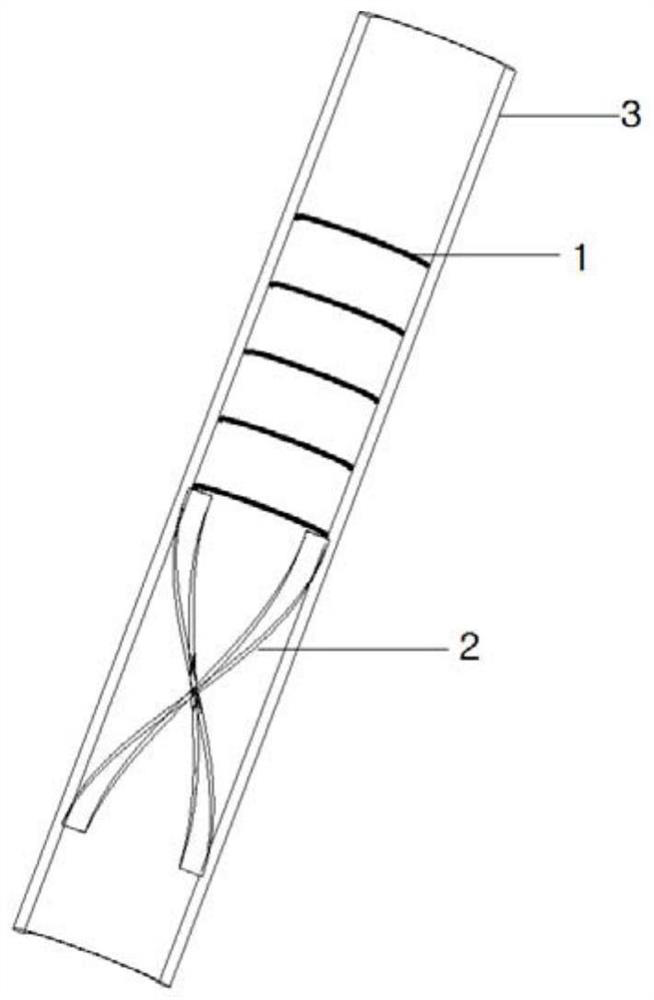

Plastic deformation method for achieving structural performance optimization of inner surface of straight pipe

ActiveCN109609743AHigh surface hardnessHigh strengthFurnace typesHeat treatment furnacesEngineeringShearing deformation

The invention belongs to the field of plastic processing, and relates to a plastic deformation method for achieving structural performance optimization of an inner surface of a straight pipe. High-speed shearing deformation is carried out on the inner surface of the metal straight pipe in a point contact mode, so that the structural performance of the inner surface of the pipe fitting is optimized. The plastic deformation method for achieving the structural performance optimization of the inner surface of the straight pipe has the following technical advantages that the point contact is introduced into the high-speed shearing plastic deformation, and effective cooling in straight pipe processing is achieved; the uniformity and the collimation degree of the wall thickness is effectively guaranteed before and after straight pipe processing; a 500-micron plastic deformation surface layer is formed on the inner surface of the straight pipe, so that the hardness and the strength of the inner surface of the straight pipe are improved by 5-20 times, and the surface quality is improved until the roughness Ra is 0.02-0.2; and the chemical activity of the inner surface of the straight pipe is greatly improved, and the temperature of chemical heat treatment such as nitrizing and carburizing is reduced by 200 DEG C or above.

Owner:YANSHAN UNIV

Oxidation-resistant coking-resistant hydrocarbon cracking furnace pipe and preparation method thereof

ActiveCN103788987AImprove toughnessAvoid enteringThermal non-catalytic crackingOxidation resistantSilicon

The invention provides an oxidation-resistant coking-resistant hydrocarbon cracking furnace pipe and a preparation method thereof. A cracking furnace pipe is used as a barrel-shaped cathode, a molybdenum elementary substance, a silicon elementary substance and a modified material are put into the barrel-shaped cathode, through a glow discharge principle, molybdenum ions, silicon ions and modified substance ions are formed, and a MoSi2-modified substance composite permeable layer is formed on the inner surface of the cracking furnace pipe. The permeable layer can reduce high temperature oxidation and carburization of the cracking furnace pipe, reduce deposition of coke on the inner surface of the cracking furnace pipe in a hydrocarbon steam-cracking process, and obviously prolongs an operation period and a use life.

Owner:CHINA PETROLEUM & CHEM CORP +1

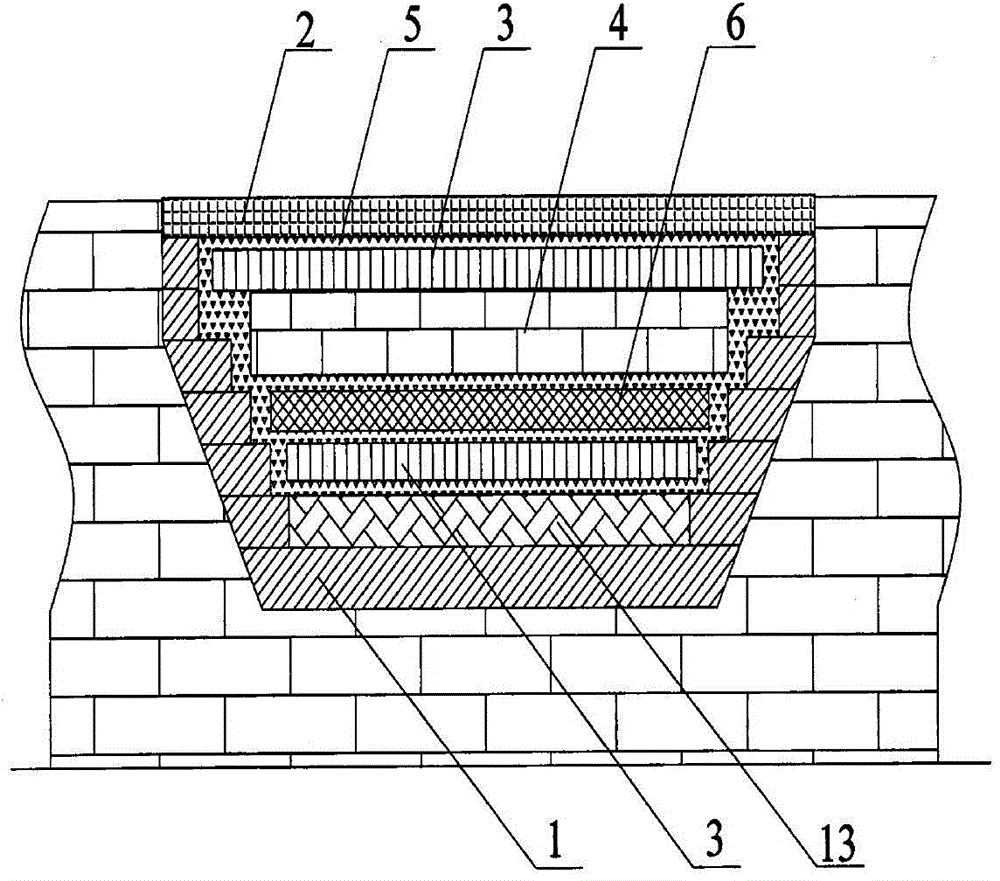

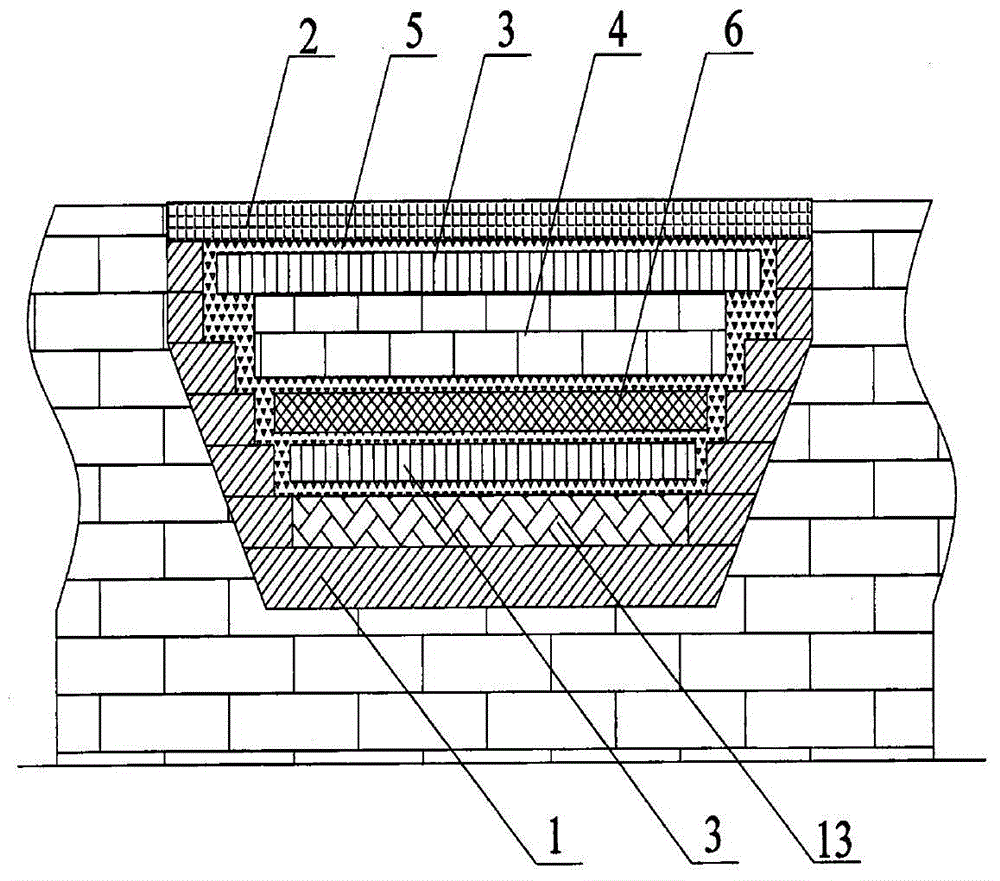

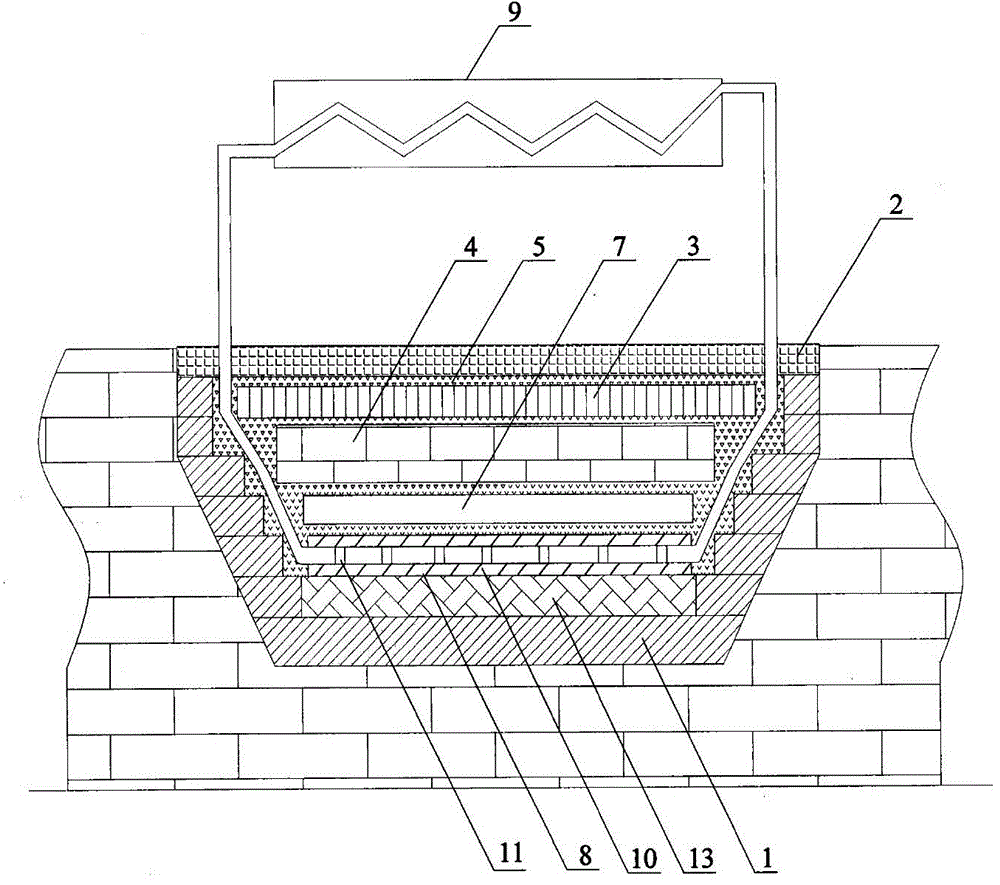

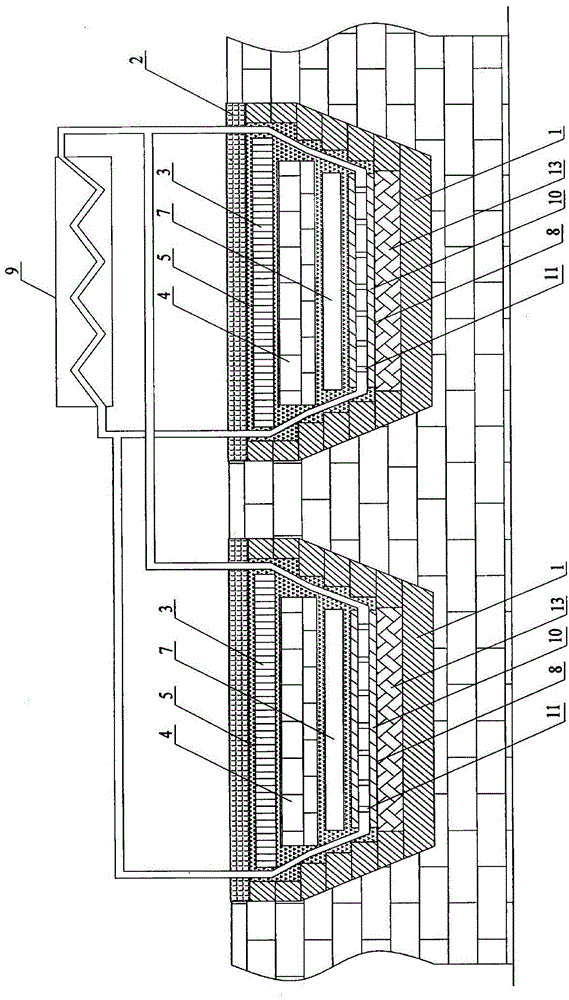

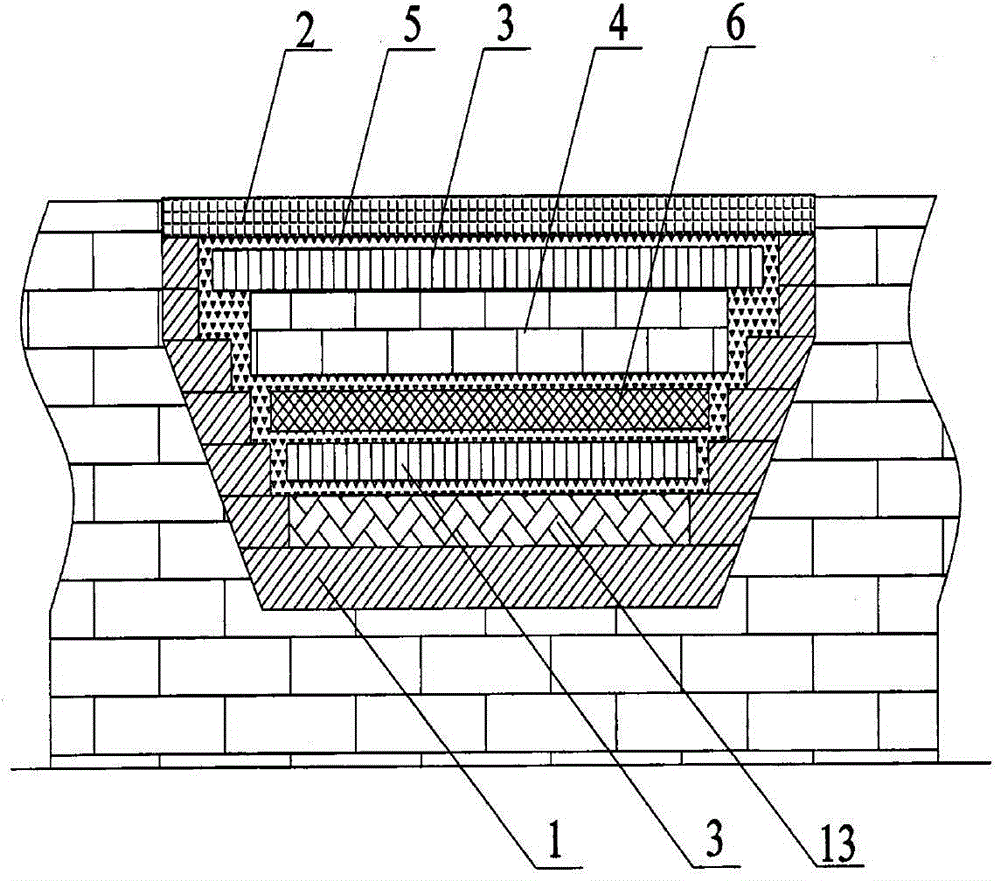

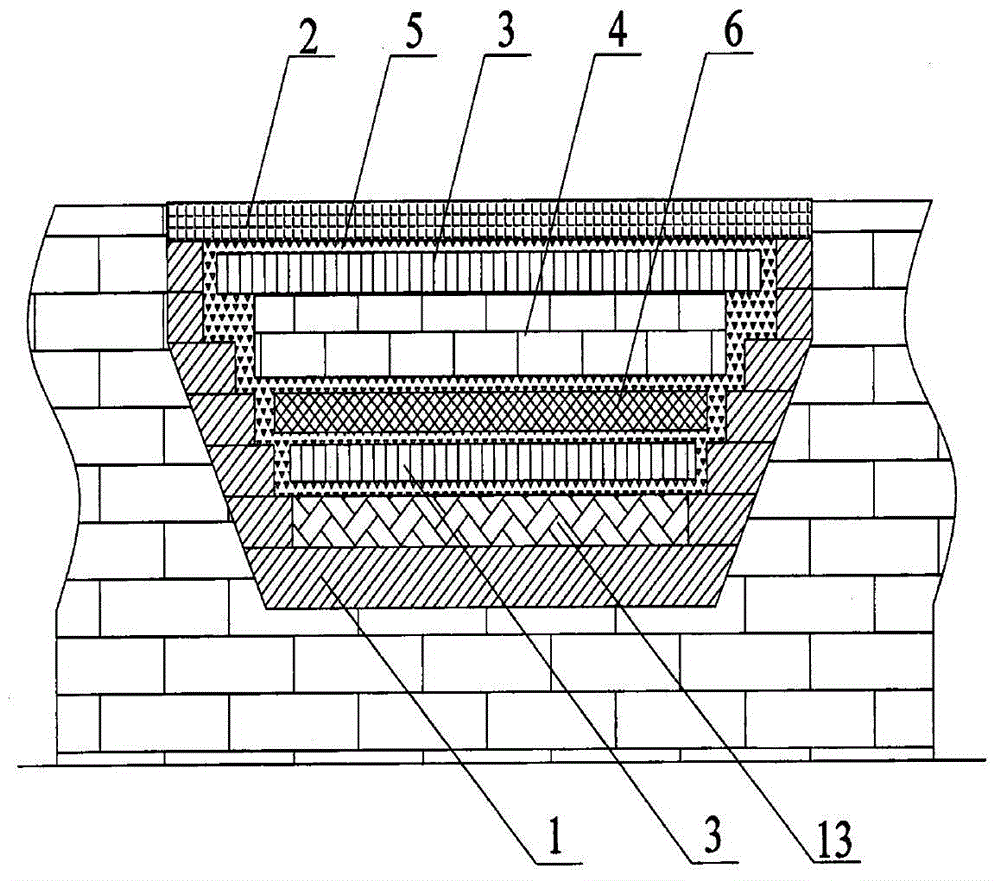

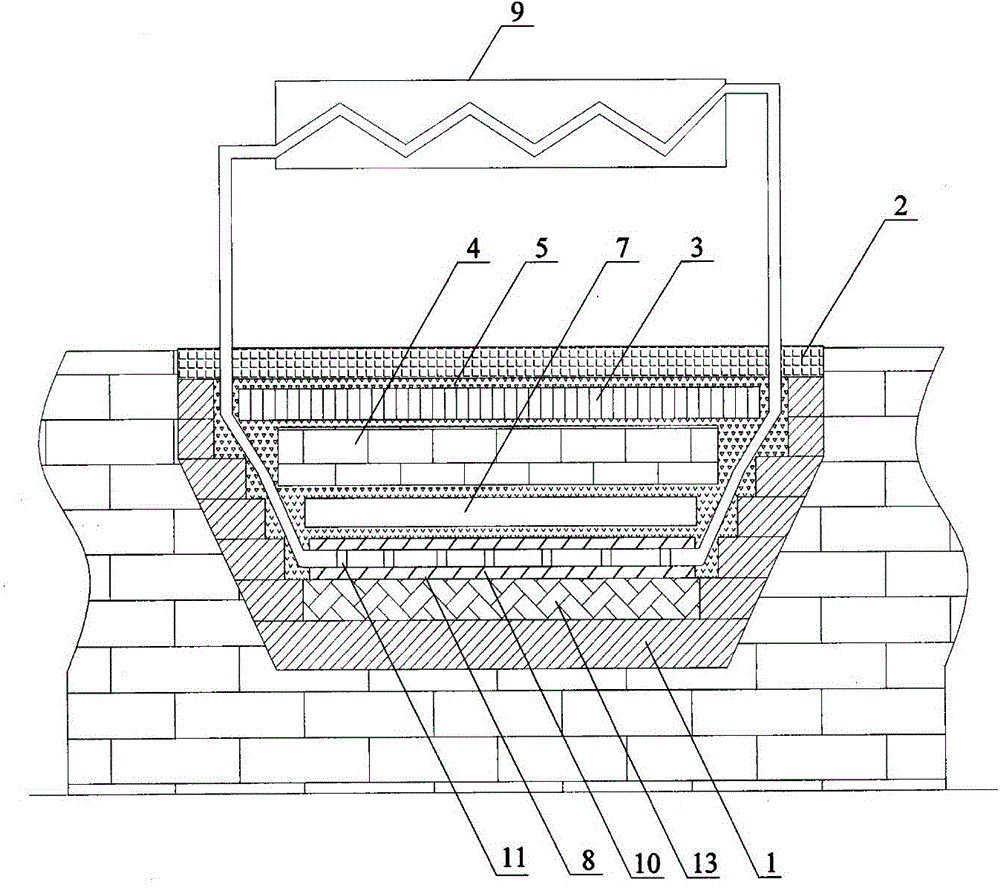

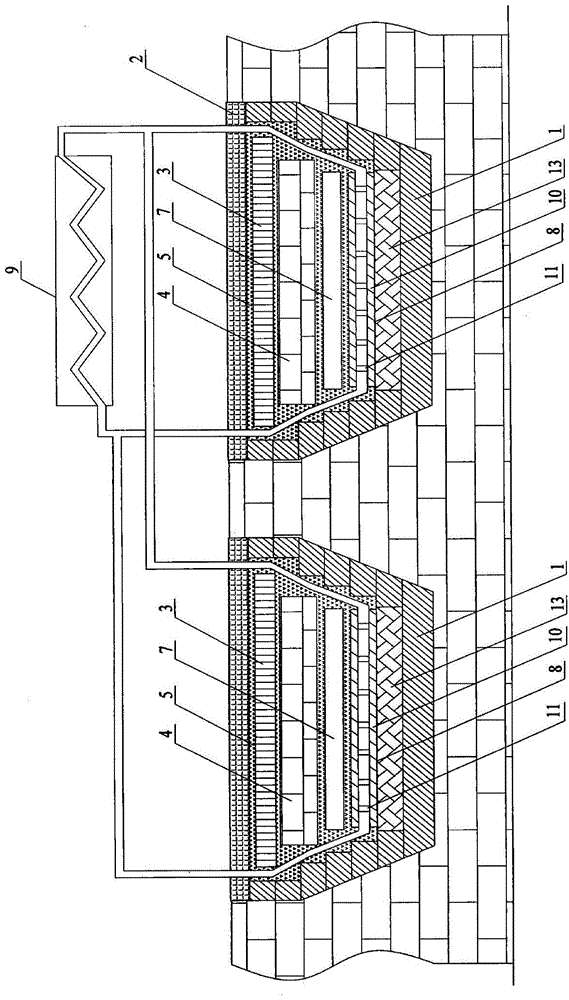

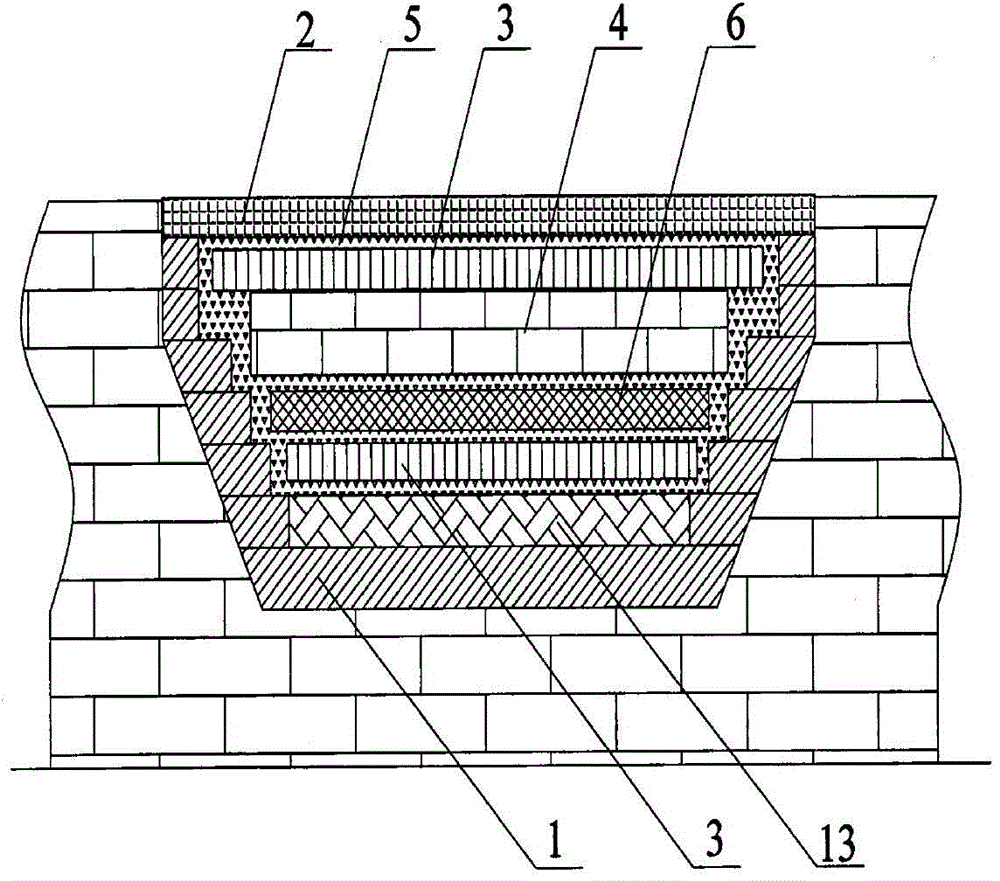

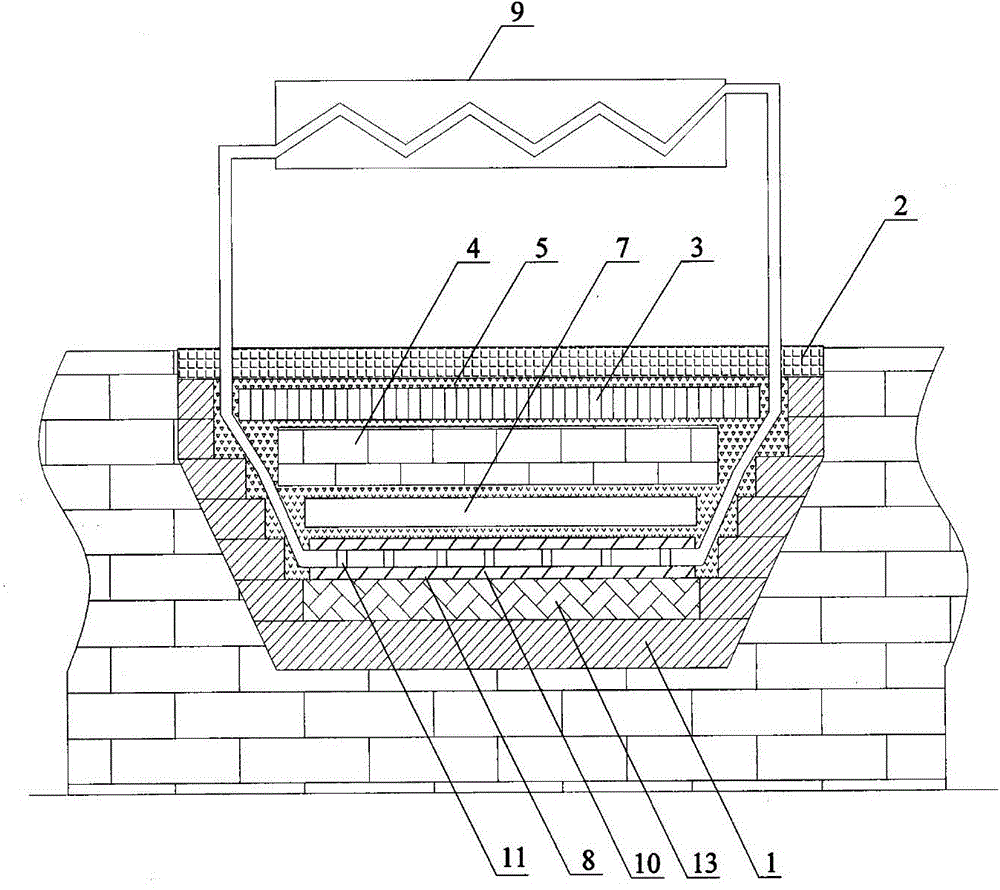

Eliminating type coke oven afterheat recovery power generating system based on voltage stabilizing power supply circuit

InactiveCN104810975AReduce dosageReasonable designAc-dc conversionIncreasing energy efficiencyBrickSlurry

The invention discloses an eliminating type coke oven afterheat recovery power generating system based on a voltage stabilizing power supply circuit. The eliminating type coke oven afterheat recovery power generating system mainly consists of a coke oven top big pit and an oven top cylinder brick covering the top surface of the coke oven top big pit, wherein a perforated steel plate, a heat insulation plate layer and a perforated steel plate are sequentially arranged inside the coke oven top big pit from bottom to top, a heat insulation brick layer arranged between the perforated steel plate and the heat insulation plate layer is formed by filling heat-resistant sealing slurry in an inside gap part of the coke oven top big pit, a heat exchanger and an evaporator forming a sealed loop are arranged outside the coke oven top big pit, an afterheat power generating system is also arranged on the evaporator, an afterheat control circuit is arranged in the afterheat power generating system, a static electricity eliminating circuit, an overcurrent protection circuit, a control type power supply circuit, a voltage stabilizing power supply circuit and a control type output circuit are arranged in the afterheat control circuit, and the overcurrent protection circuit, the control type power supply circuit, the voltage stabilizing power supply circuit and the control type output circuit are in sequential connection.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

High performance coatings and surfaces to mitigate corrosion and fouling in fired heater tubes

InactiveUS8748008B2Reduce carburizationReduced form requirementsMuffle furnacesOther heat production devicesMulliteSpinel

A fired heater tube that is resistant to corrosion and fouling is disclosed. The fired heater tube comprises an advantageous high performance coated material composition resistant to corrosion and fouling comprises: (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal layer, wherein P is substantially comprised of alumina, chromia, silica, mullite, spinels, and mixtures thereof, Q comprises Cr, and at least one element selected from the group consisting of Ni, Al, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Re, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof, and R is selected from the group consisting of low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys.

Owner:EXXON RES & ENG CO

Alumina forming bimetallic tube for refinery process furnaces and method of making and using

InactiveCN104302741AReduce corrosionReduce foulingThermal non-catalytic crackingPlasma welding apparatusMulliteSpinel

Provided is a bimetallic tube for transport of hydrocarbon feedstocks in refinery process furnaces, and more particularly in furnace radiant coils, including: i) an outer tube layer being formed from stainless steels including chromium in the range of 15.0 to 26.0 wt.% based on the total weight of the stainless steel; ii) an inner tube layer being formed from an alumina forming bulk alloy including 5.0 to 10.0 wt.% of Al, 20.0 wt.% to 25.0 wt.% Cr, less than 0.4 wt.% Si, and at least 35.0 wt.% Fe with the balance being Ni, wherein the inner tube layer is formed plasma powder welding the alumina forming bulk alloy on the inner surface of the outer tube layer; and iii) an oxide layer formed on the surface of the inner tube layer, wherein the oxide layer is substantially comprised of alumina, chromia, silica, mullite, spinels, or mixtures thereof. Also provided are methods of making and using the bimetallic tube.

Owner:EXXON RES & ENG CO

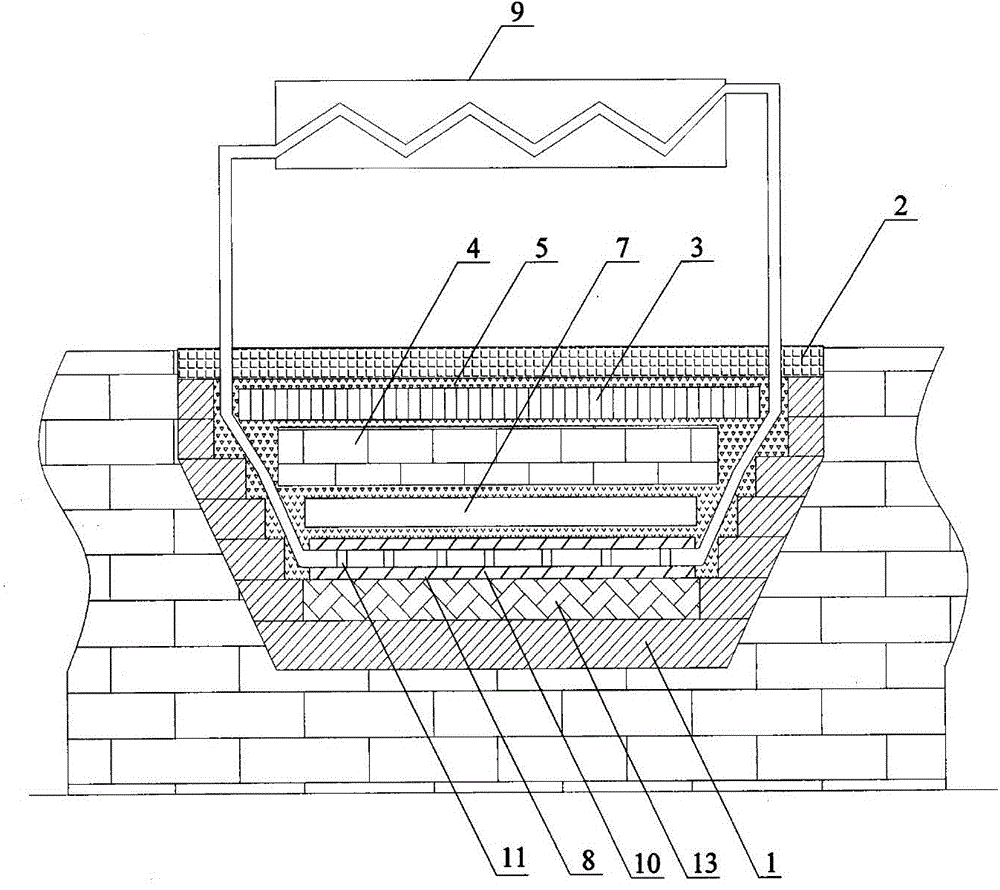

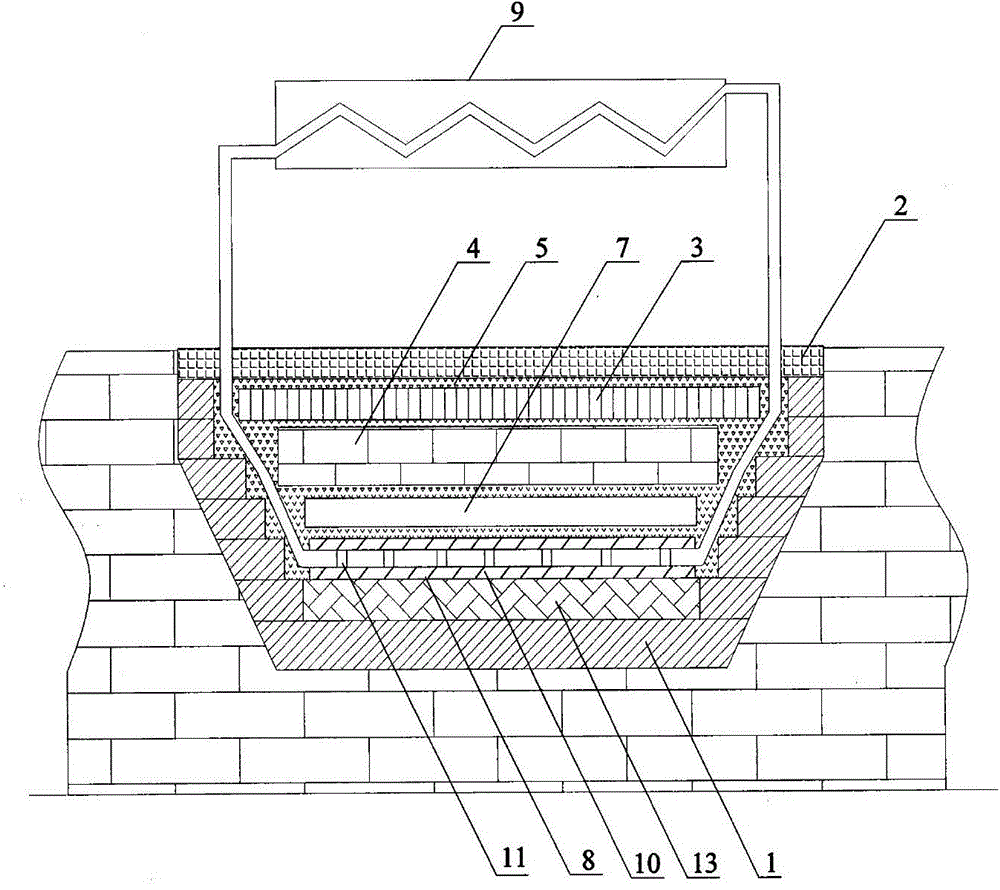

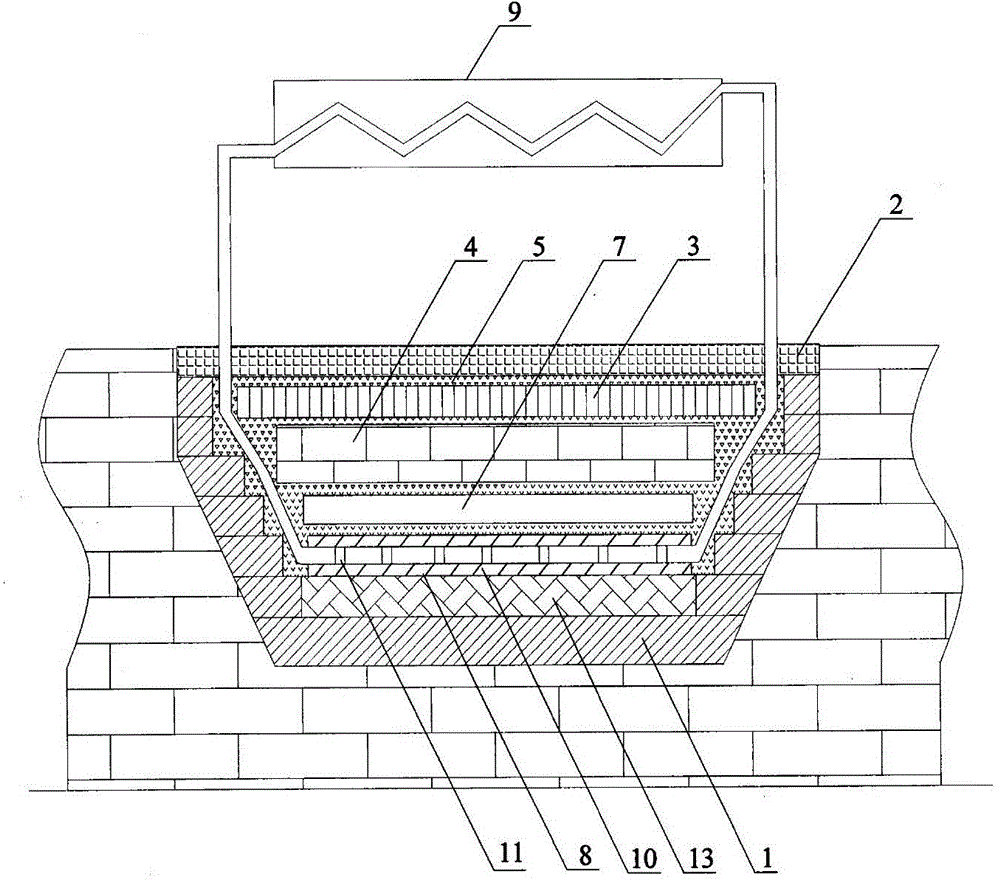

Coke oven roof waste heat recovery power generation system based on power supply adjusting circuit

InactiveCN104910925AReduce dosageReasonable designEnergy inputCoke oven detailsBrickThermal insulation

The invention discloses a coke oven roof waste heat recovery power generation system based on a power supply adjusting circuit. The system is composed of a coke oven roof pit and roof quarry tiles covering the surface of the roof. A hole steel plate, a thermal insulation plate layer and a hole steel plate are arranged inside the coke oven roof pit from bottom to top in order. an insulation tile layer arranged between the hole steel plate and the thermal insulation plate layer is poured with heatproof sealing slurry at the internal seam of the coke oven roof pit. A heat exchanger and an evaporator forming an enclosed loop are arranged outside the coke oven roof pit. A waste heat power generation system is arranged on the evaporator. A waste heat control circuit is arranged in the waste heat power generation system. A control-type power supply circuit, a power supply adjusting circuit and a control-type output circuit are arranged in the waste heat control circuit and the control-type power supply circuit, the power supply adjusting circuit and the control-type output circuit are connected in order.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

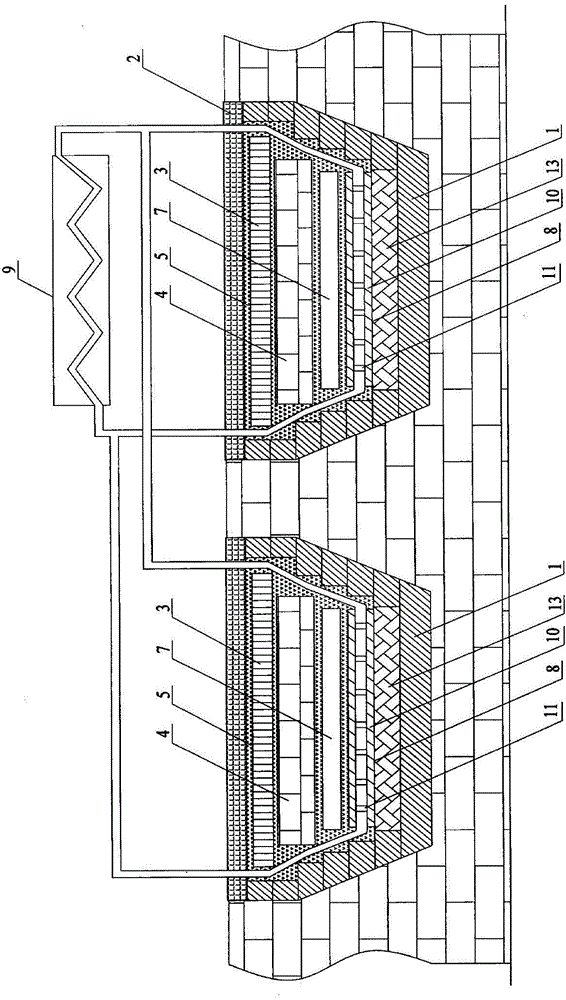

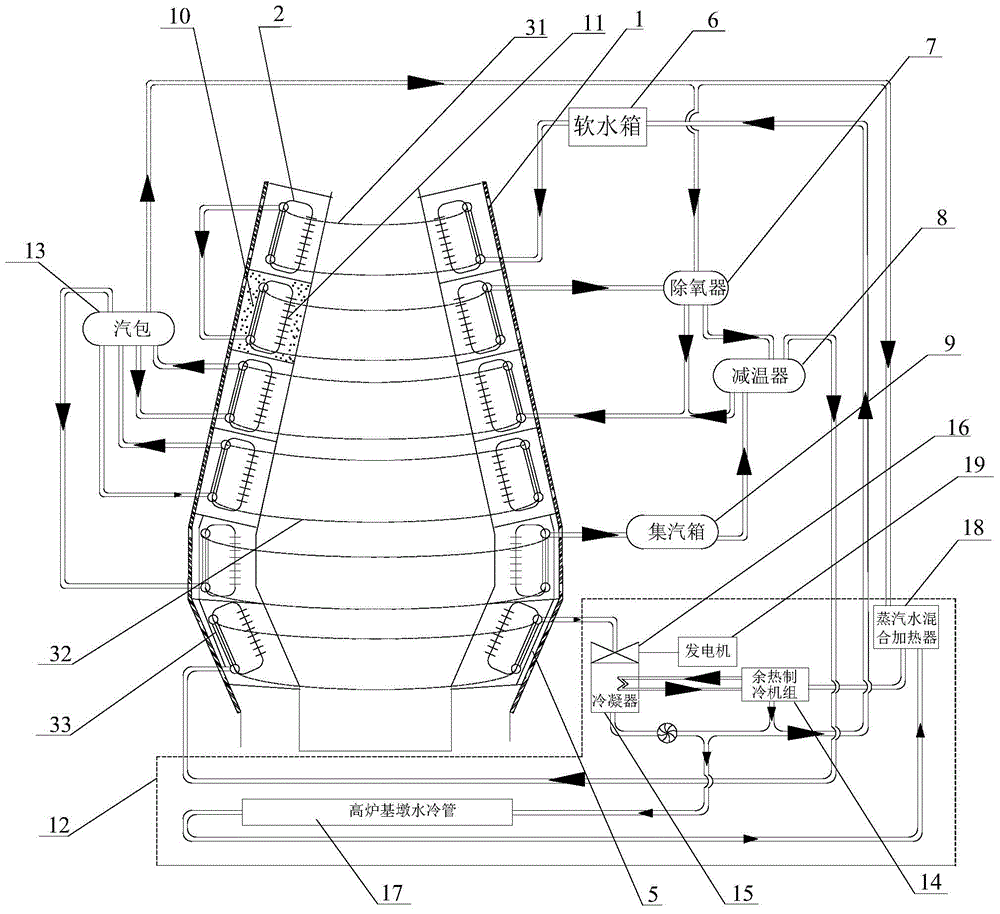

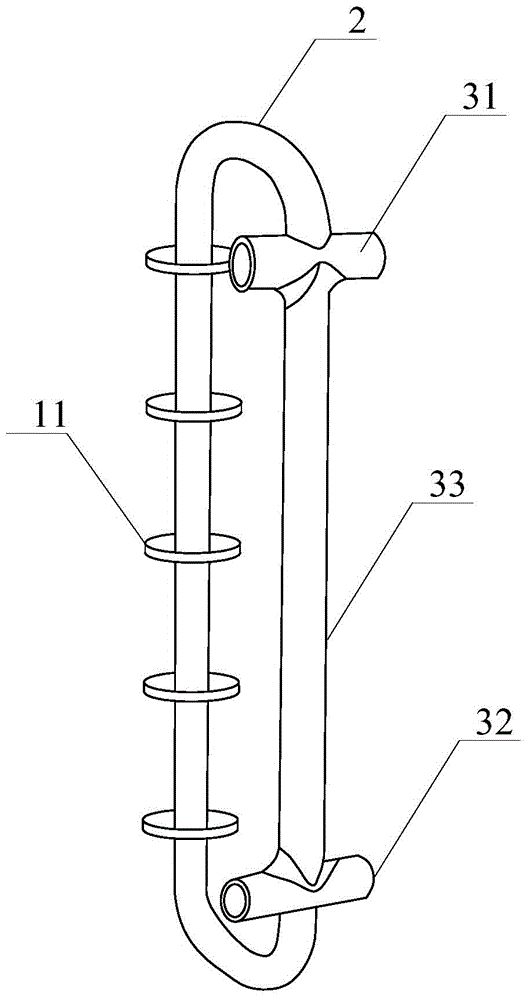

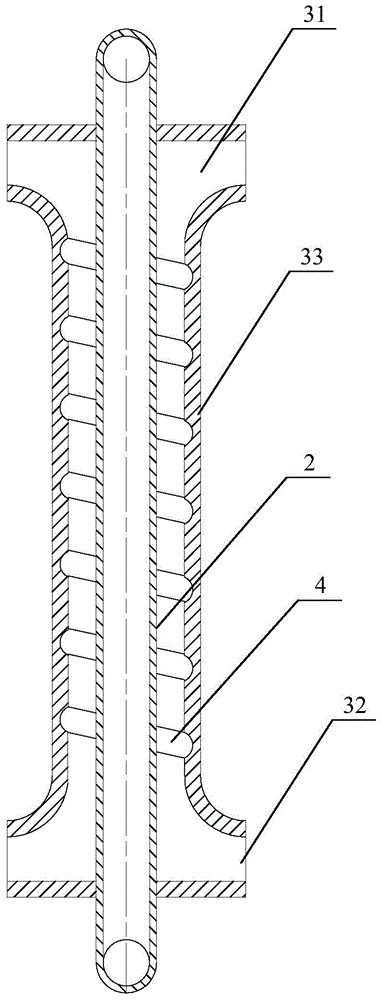

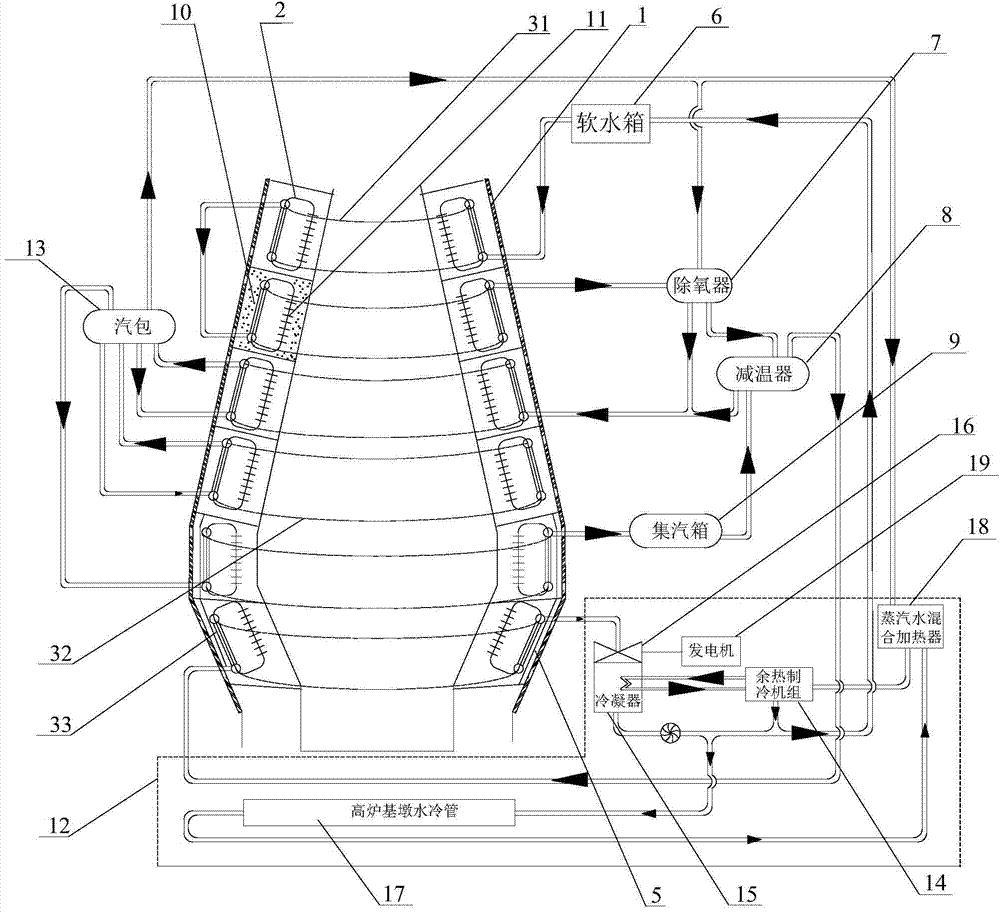

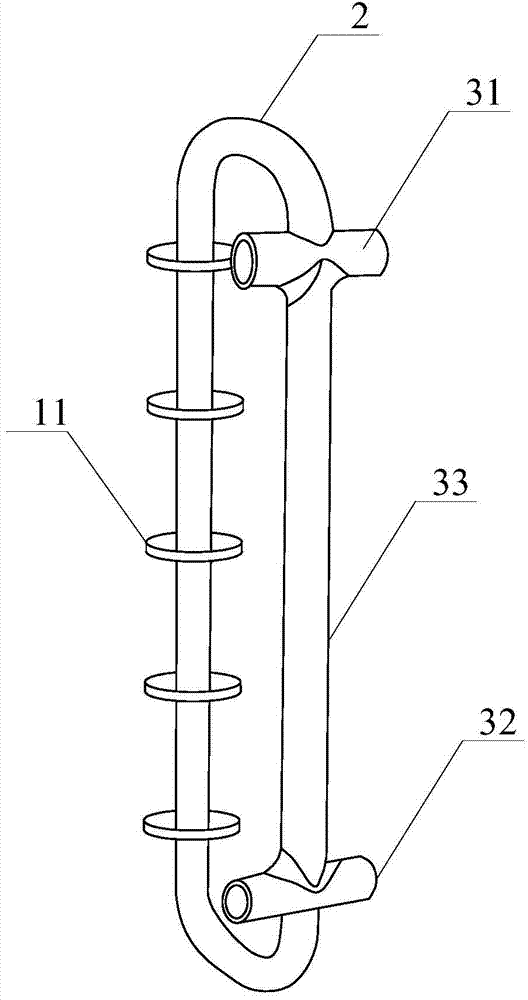

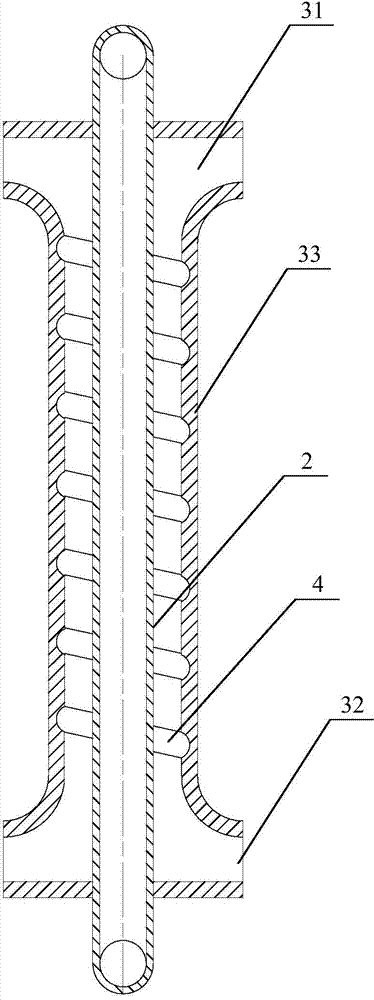

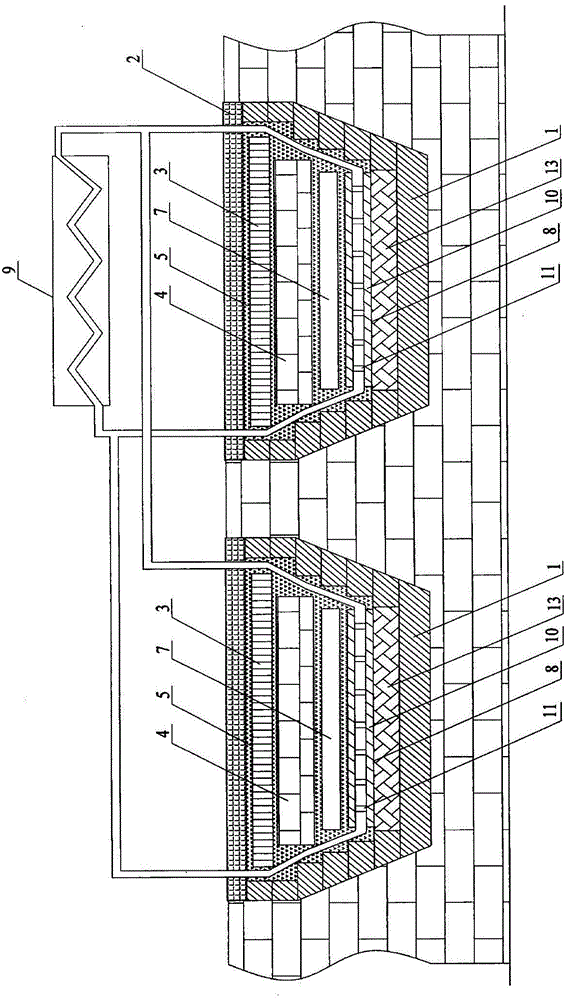

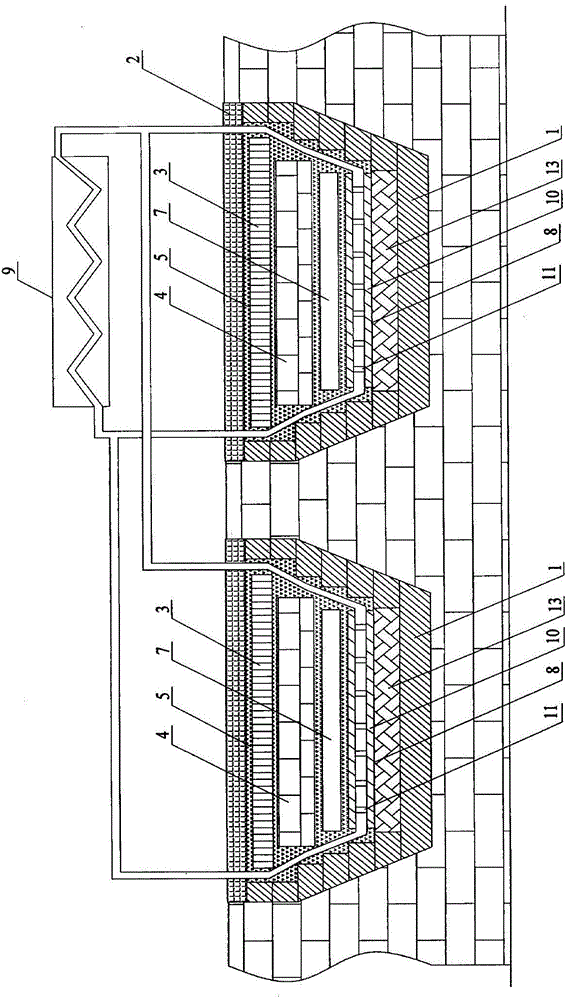

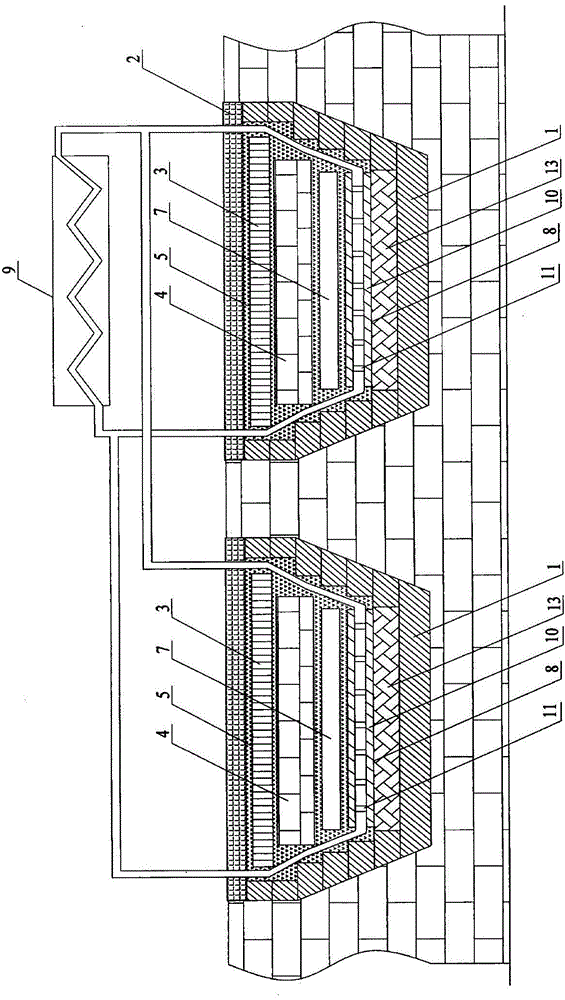

Current source feedback type waste heat generating system based on blast furnace superconducting cooling

InactiveCN104946834AReduce dosageReasonable designBlast furnace detailsIncreasing energy efficiencyControl treatmentEngineering

The invention discloses a current source feedback type waste heat generating system based on blast furnace superconducting cooling. The current source feedback type waste heat generating system based on the blast furnace superconducting cooling mainly comprises a blast furnace body (1), an electrical power generating system (12), a steam utilizing device, more than one superconducting annular heat exchange ring (2) which is hierarchically arranged along the side wall of the blast furnace body (1) in a surrounding manner and a waste heat control treatment system. The current source feedback type waste heat generating system based on the blast furnace superconducting cooling has the advantages that hot water after heat exchange is discharged in a concentrated manner by virtue of the superconducting annular heat exchange rings which are embedded in the side wall of the blast body and a corresponding annular pipeline system, so that heat exchange intensity is improved, heat exchange efficiency and cooling efficiency are improved; and temperature of the traditional cooling water is increased to 250 DEG C from 40 DEG C, and then the traditional cooling water is overheated to 400 DEG C by applying the superconducting heat exchange rings twice, so that cooling waste used for power generation is realized.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Ultra-high pressure brazed connection method for connecting wolfram-diamond/copper-low activation steel

InactiveCN103084690AReduce thermal stressConduct as soon as possibleSoldering apparatusUltra high pressureCopper foil

Provided is an ultra-high pressure brazed connection method for connecting wolfram-diamond / copper-low activation steel. The method relates to the preparation of a water cooling wolfram module of a divertor of a fusion reactor device. The method comprises using the diamond / copper composite materials of different diamond volume ratios as the intermediate layers between the wolfram and the low activation steel, and a layer of CuCrZr or oxygen-free copper (OFC) foil with the thickness of 0.3 mm is added between the diamond / copper composite materials and the wolfram and between the diamond / copper composite materials and the low activation steel, then a cladding type structure is adopted to put the raw materials in a graphite die in sequence, the raw materials are placed into a six-surface diamond presser under the packaging of a steel cup, a magnesium cup, graphite paper and a pyrophyllite wrap sleeve to carry out ultra-high pressure electrifying welding, and wolfram stack-diamond / copper-low activation steel is ultimately formed into an integrate wolfram module at one time. The ultra-high pressure brazed connection method for connecting wolfram-diamond / copper-low activation steel can achieve the welding of the wolfram stack-diamond / copper-low activation steel at one time in a short time, a welding interface is intact, welding strength is high, and the heat-conducting property of the wolfram module is good.

Owner:UNIV OF SCI & TECH BEIJING

Blast furnace superconductive cooling waste heat power generation system based on bias adjustable current source

InactiveCN104846139AReduce dosageReasonable designCooling devicesIncreasing energy efficiencyEngineeringHeat transfer efficiency

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Support member for high-temperature heat-treated metal molding object and process for production thereof

InactiveUS20040258950A1Enhanced inhibitory effectGood prevention effectNatural mineral layered productsThin material handlingCompression moldingPowder mixture

A carbonaceous support member for a high-temperature heat-treated metal molding object, particularly a setter for heat-treatment in powder metallurgy, is formed as a carbon-ceramic composite shaped product having a bulk density of 1.2-1.6 g / ml and including a carbonaceous matrix and 3-20 wt. % of ceramic particles which are uniformly dispersed in the carbonaceous matrix and partly exposed to the surface of the composite. The support member can effectively prevent carburization of a metal molding object supported thereby during the heat-treatment without causing a problem of peeling of coating layer as encountered in a ceramic-coated support member. The support member may be prepared by compression molding of a powdery mixture of a fine carbon precursor and ceramic particles, followed by heating at 1000-2000° C. to carbonize the fine carbon precursor.

Owner:KUREHA KAGAKU KOGYO KK

Method for suppressing coking and carbonizing for hydrocarbons steam cracking unit

ActiveCN101161785BShort injection timeStop cokingThermal non-catalytic crackingEthyleneMaterials science

The invention provides a method for restraining coking and carburizing of hydrocarbon steam cracking device, including the following steps: during hot standby of a cracking furnace, combination which prevents coking and carburizing is injected into the cracking furnace, wherein, the combination is sol combination containing at least one sort of silica sol, aluminum sol and zirconium sol. The method which is simple and feasible, environmental friendly and low in cost does not influence the downstream system of an ethylene plant; meanwhile, the method can effectively restrain coking and carburizing of cracking furnace tube so as to prolonging service life and operation cycle of the cracking furnace.

Owner:CHINA PETROLEUM & CHEM CORP +1

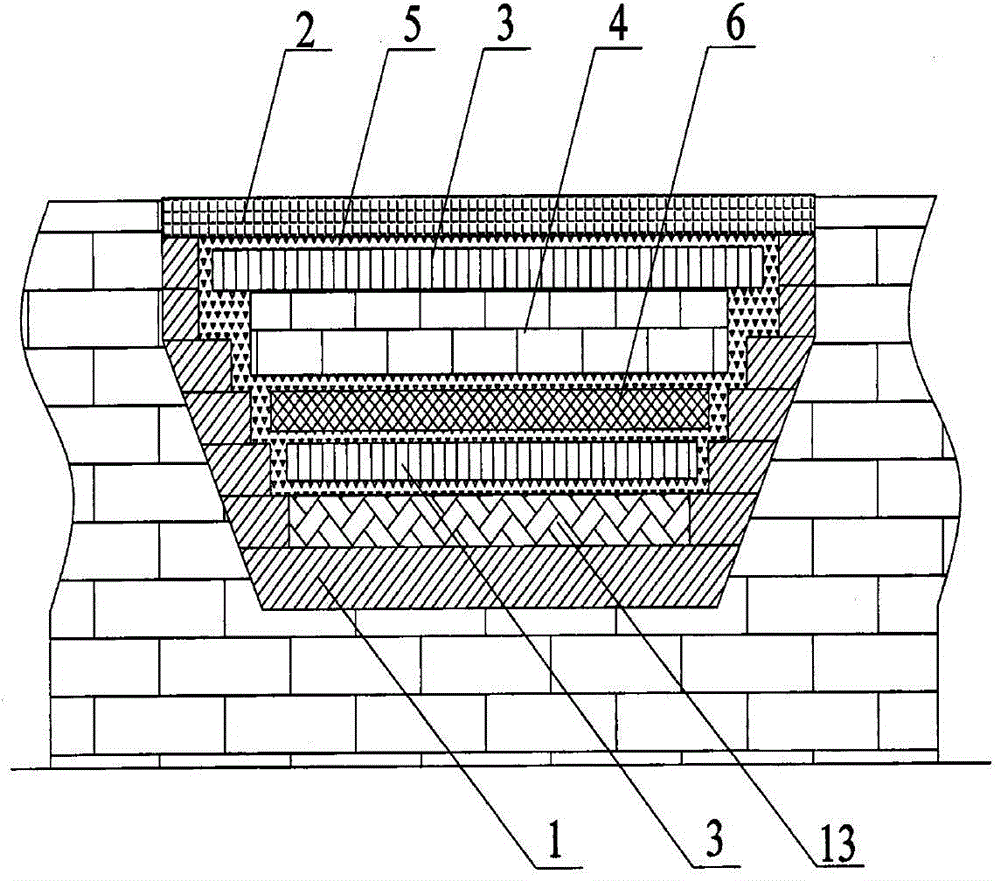

Thermal protection type coke oven waste heat recovery power generation system based on power source voltage adjustment circuit

InactiveCN104833222AReduce dosageReasonable designIncreasing energy efficiencyMachines/enginesBrickThermal insulation

The invention discloses a thermal protection type coke oven waste heat power generation system based on a power source voltage adjustment circuit. The system is mainly composed of coke oven top large pits and oven top clinker bricks covering the surfaces of the tops of the coke oven top large pits, a pored steel plate, a thermal insulation board layer and a pored steel plate are arranged inside each coke oven top large pit in sequence from bottom to top, a thermal insulation brick layer is arranged between each pored steel plate and the corresponding thermal insulation board layer, gaps, inside the corresponding coke oven top large pit, of each thermal insulation brick layer are filled with heatproof sealing slurry in a poured mode, heat exchangers and an evaporator forming a closed loop are arranged outside the coke oven top large pits, a waste heat power generation system body is further arranged on the evaporator, a waste heat control circuit is arranged in the waste heat power generation system body, and a thermal inductance automatic switching circuit and a control type power source circuit, the power source voltage adjustment circuit and a control type output circuit which are connected in sequence are arranged in the waste heat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

A kind of powder catalyst for synthesizing ultrafine particle diamond

ActiveCN104226355BIncreased ultrafine particle contentIncreased content of ultrafine particlesPhysical/chemical process catalystsUltra-high pressure processesSingle crystalSingle crystal diamond

The invention discloses a powder catalyst for synthesizing ultrafine particle diamond. Expressed in weight percent, the powder catalyst is mainly made of the following alloy components: Fe 20%-25%, Co 3%-5%, Ce 0.5%-2%, Mn 3%-5%, SiC 0.5-1% , Mo 0.5 ~ 1%, the balance is Ni. The technical scheme of the invention can be used to produce high-purity ultrafine particle spherical or nearly spherical powder catalyst, and the particle size of the obtained powder catalyst is 600-1000 mesh. Applying the powder catalyst of the present invention to the synthesis of ultrafine diamond single crystals can produce single crystal diamonds with a fineness of less than 400 mesh.

Owner:HENAN POWER NEW MATERIAL

Protection type coke oven waste heat recovery power generation system based on boost power supply circuit

InactiveCN104833221AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickClosed loop

The invention discloses a protection type coke oven waste heat recovery power generation system based on a boost power supply circuit. The system is mainly composed of a coke oven top large pit and oven top quarry tiles covering the surface of the top of the coke oven top large pit. A porose steel plate, a heat insulation plate layer and a porose steel plate are sequentially arranged in the coke oven top large pit from bottom to top. Heat preservation brick layers between the porose steel plates and the heat insulation plate layer are formed by filling the inner gaps inside the coke oven top large pit with heat-resisting sealing slurry. A heat exchanger and an evaporator which form a closed loop are arranged outside the coke oven top large pit. A waste heat power generation system is arranged on the evaporator. A waste heat control circuit is arranged in the waste heat power generation system. An over-current protection circuit, a control type power supply circuit, the boost power supply circuit and a control type output circuit are connected in sequence and arranged in the waste heat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Coke oven top waste heat recycling and electricity generation system based on efficient drive power source circuit

InactiveCN104913646AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickSlurry

The invention discloses a coke oven top waste heat recycling and electricity generation system based on an efficient drive power source circuit. The coke oven top waste heat recycling and electricity generation system is mainly composed of a large coke oven top pit and oven top quarry tiles covering the surface of the top of the pit. The large coke oven top pit is internally and sequentially provided with a porous steel plate, a heat insulation plate layer and the porous steel plate from bottom to top. A heat preservation tile layer arranged between the porous steel plates and the heat insulation plate layer is formed by pouring heat-resisting sealing slurry into seams of the large coke oven top pit. A heat exchanger and an evaporator for forming a sealing loop are arranged outside the large coke oven top pit. The evaporator is further provided with a waste heat electricity generation system. The waste heat electricity generation system is internally provided with a waste heat control circuit. The waste heat control circuit is internally provided with a control type power circuit, the efficient drive power source circuit, and a control type output circuit which are sequentially connected.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Alarm type coke oven waste heat recovery power generation system based on power supply adjustment circuit

InactiveCN104836374AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickClosed loop

The invention discloses an alarm type coke oven waste heat recovery power generation system based on a power supply adjustment circuit. The system is mainly formed by a coke oven top large pit and oven top clinker tiles which cover the top surface of the coke oven top large pit. The internal part of the coke oven top large pit is orderly provided with a perforated steel plate, a heat insulation plate layer and a perforated steel plate from bottom to top. A heat preservation tile layer arranged between the perforated steel plate and the heat insulation plate layer, and the internal gap of the coke oven top large pit is filled with heat resistant sealing slurry. The external part of the coke oven top large pit is provided with a heat exchanger and an evaporator to form a closed loop. The evaporator is provided with a waste heat power generation system which is internally provided with a waste heat control circuit. The waste heat control circuit is internally provided with a power-off alarm circuit and is also provided with an overcurrent protection circuit, a control type power supply circuit, a power supply adjustment circuit and a control type output circuit which are connected in order.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

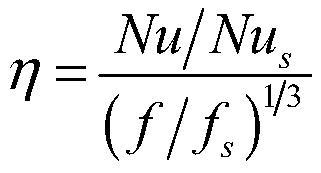

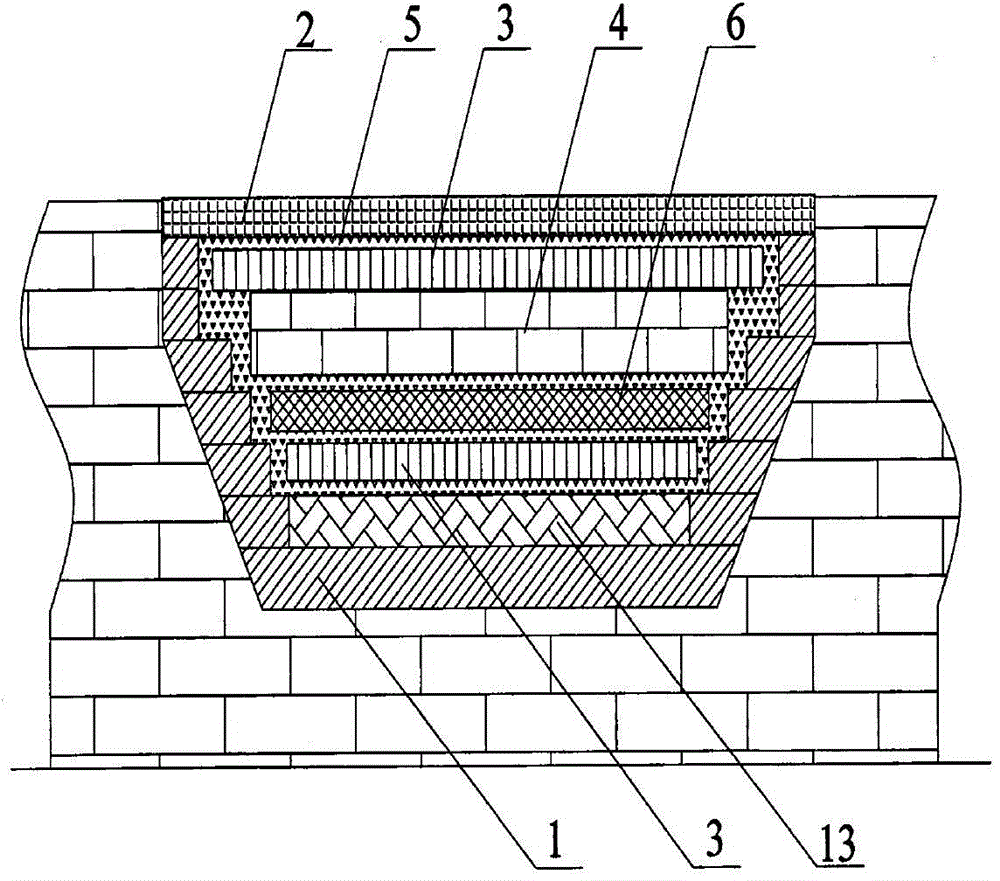

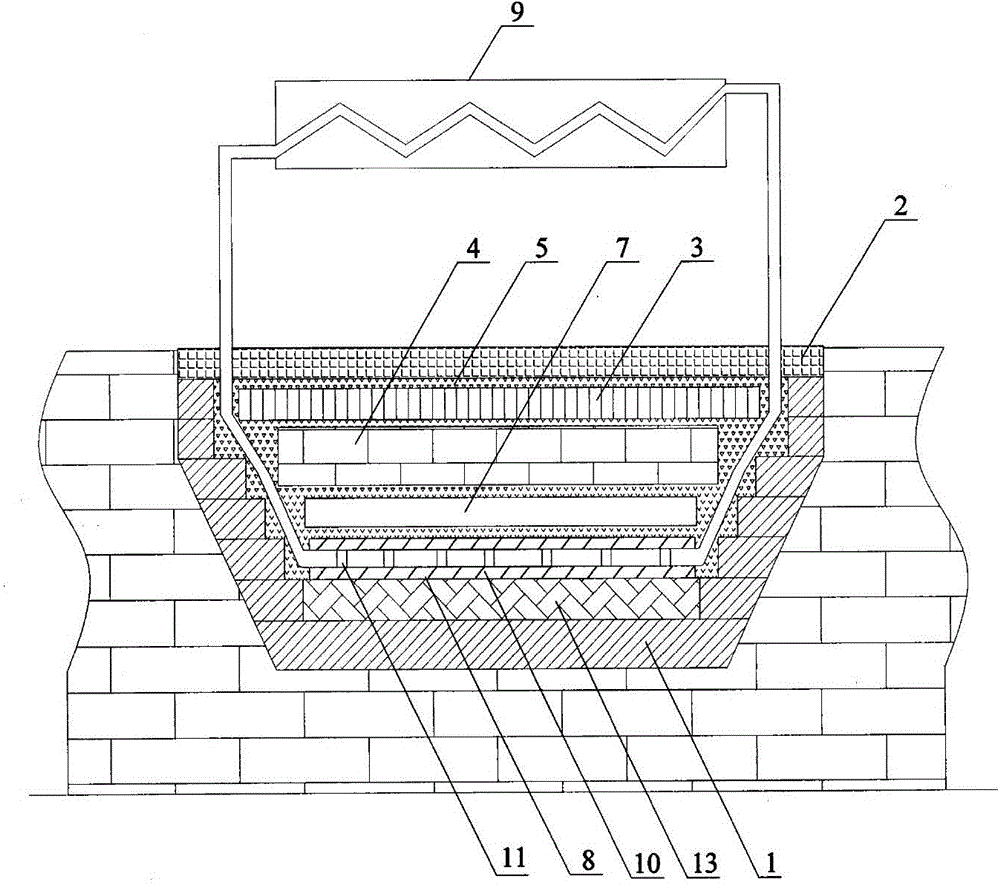

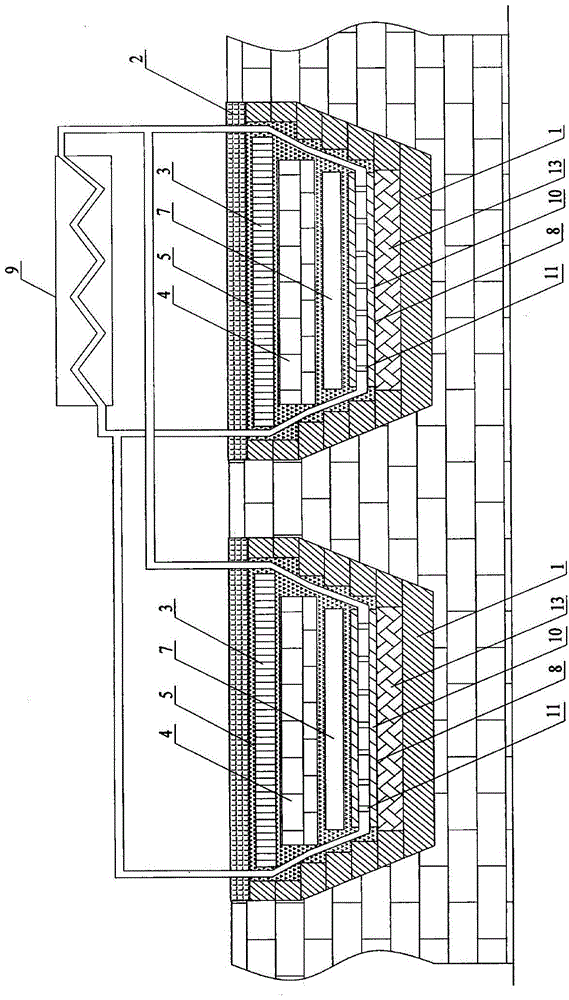

Heat-conducting furnace tube for two-stroke radiation section ethylene cracking furnace as well as preparation method and application of heat conduction furnace tube

ActiveCN112745885AImprove heat transfer performanceExtended service lifeThermal non-catalytic crackingChemical industryMetallurgyEngineering

The invention relates to the field of heat-conducting furnace tubes for ethylene cracking furnaces, and discloses a heat-conducting furnace tube for a two-stroke radiation section ethylene cracking furnace, a preparation method of the heat-conducting furnace tube and an application of the heat-conducting furnace tube in a cracking furnace. The heat-conducting furnace tube comprises a furnace tube main body, wherein multiple groups of heat-conducting components are sequentially and repeatedly arranged on the inner side wall of the furnace tube main body in the length direction of the furnace tube main body; first heat conduction pieces and second heat conduction pieces, wherein the multiple first heat conduction pieces are arranged, surround the cross section of the inner side wall of the furnace tube body by a circle and are formed by protruding towards the interior of the furnace tube body; and the second heat conduction piece is spirally arranged along the axial direction of the furnace tube main body. The heat-conducting furnace tube has a good heat transfer effect, the heat transfer strengthening comprehensive factor of the heat-conducting furnace tube is remarkably improved by 15-27%, and meanwhile the coking amount and the carburization phenomenon of the heat-conducting furnace tube can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Voltage stabilizing power supply circuit based elimination type coke oven waste heat power generation system

InactiveCN104819649AReduce dosageReasonable designIncreasing energy efficiencyMachines/enginesBrickCoke oven

The invention discloses a voltage stabilizing power supply circuit based elimination type coke oven waste heat power generation system. The voltage stabilizing power supply circuit based elimination type coke oven waste heat power generation system is mainly formed by a large hole and an oven top clinker brick, wherein the large hole is formed at the oven top of a coke oven and the oven top clinker brick covers the surface of the top of the large hole; a porose steel plate, a heat insulation plate layer and a porose steel plate are arranged inside the large hole from bottom to top in turn; an internal gap formed between the large hole and a heat insulation brick layer which is arranged between each porose steel plate and the heat insulation plate layer is filled with heatproof sealing paste; a heat exchanger and an evaporator which form a closed circuit are arranged outside the large hole; the evaporator is provided with a waste heat power generation system; a waste heat control circuit is arranged in the waste heat power generation system; a static elimination circuit, a control type power supply circuit, a voltage stabilizing power supply circuit and a control type output circuit are arranged in the waste heat control circuit, wherein the control type power supply circuit, the voltage stabilizing power supply circuit and the control type output circuit are connected in turn.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com