Heat-conducting furnace tube for two-stroke radiation section ethylene cracking furnace as well as preparation method and application of heat conduction furnace tube

A technology of ethylene cracking furnace and heat conduction furnace, which is applied in the direction of hydrocarbon cracking, cracking, non-catalytic thermal cracking, etc., can solve the problems of poor heat transfer effect, prolonged operation period, easy coking and carburizing, etc., and reduce the amount of coking. , Improve heat transfer performance, reduce the effect of carburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Preferably, the preparation method of the reinforced coating includes: mixing raw materials with water to form a slurry, spraying it on the surface of the heat conducting layer, and then sintering at a temperature of 1000-1100°C to form a reinforced coating;

[0045] Based on the total weight of the strengthening coating, the strengthening coating includes SiO in weight percentage 2 45-80% by weight, K 2 O 10-25% by weight, Al 2 o 3 0-10% by weight, MgO 0-10% by weight, ZnO 0-20% by weight, Co 3 o 4 0-5% by weight, Na 2 O 0-10% by weight.

[0046] According to the above method, a reinforcing coating is provided on the surface of the heat conducting layer to reduce the interface thermal resistance between the heat conducting layer and the reinforcing coating, improve the heat transfer performance of the heat conducting furnace tube, and effectively reduce the amount of coking on the inner wall of the heat conducting furnace tube.

[0047] The third aspect of the ...

Embodiment 1

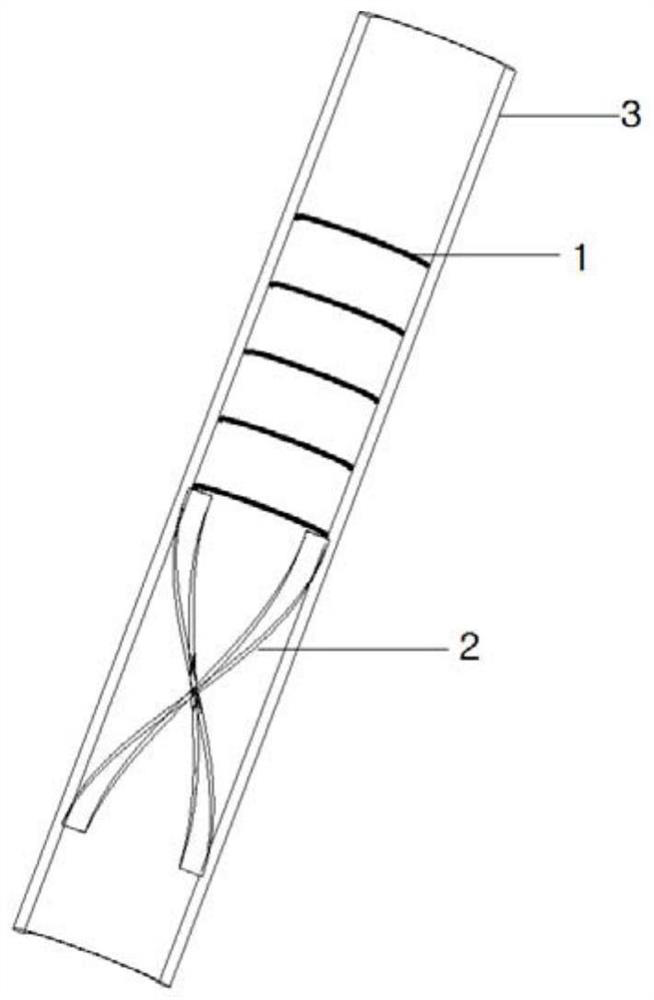

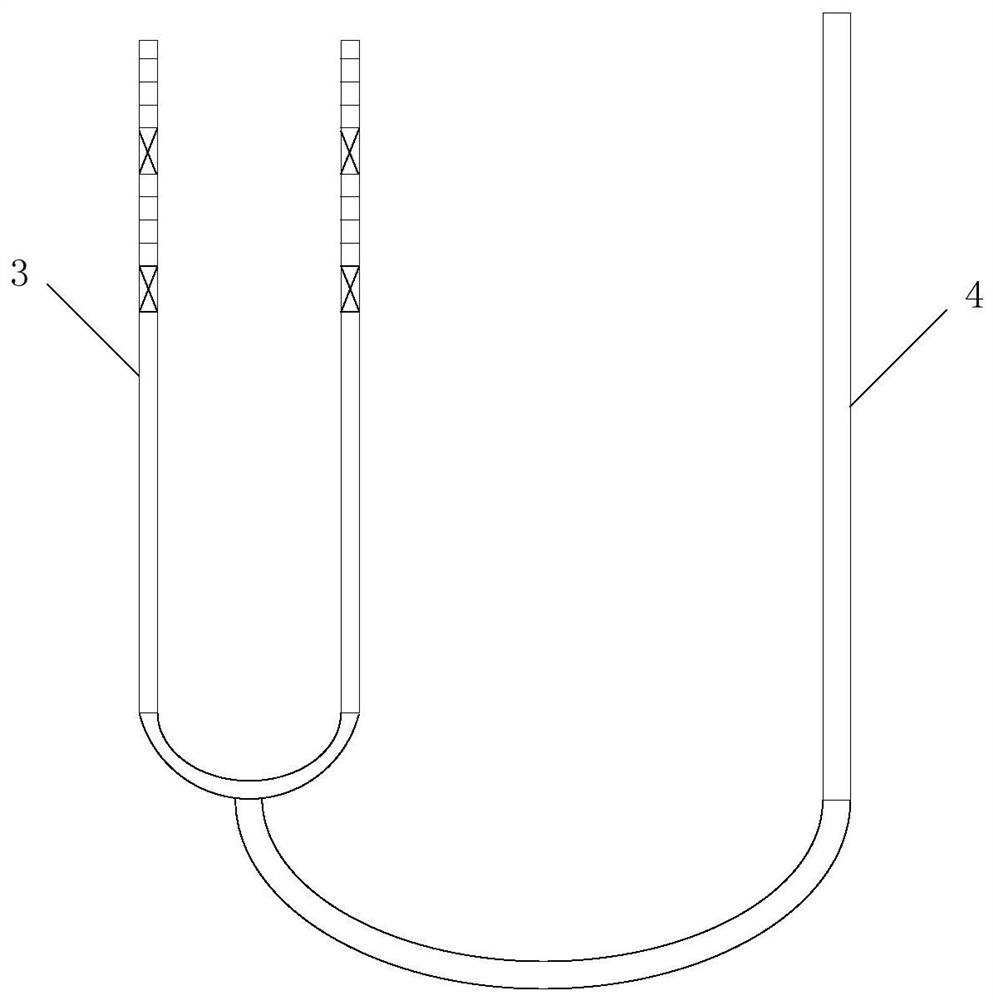

[0059] This embodiment is used to provide a heat conduction furnace tube, such as figure 2 As shown, it is a two-pass radiant section cracking furnace tube comprising a first-pass furnace tube 3 and a second-pass furnace tube 4 .

[0060] The inner diameter of the main body of the furnace tube D = 50mm, the length of the main body of the furnace tube L = 13m, such as figure 2 As shown, 8 sets of heat conducting members are evenly arranged on the two ends of the U-shaped tube along the axial direction of the furnace tube, and the extension length of the 8 sets of heat conducting members along the axial direction of the main body of the furnace tube is H=4m.

[0061] The first heat conduction element 1 is a circular ring formed around the cross-section of the inner wall of the main body of the furnace tube, and the diameter d of the inner ring of the first heat conduction element 1 is 12.5mm. A set of heat conduction members includes 15 first heat conduction elements 1 , and ...

Embodiment 2

[0066] This embodiment is used to provide a heat conduction furnace tube, such as figure 2 As shown, it is a two-pass radiant section cracking furnace tube comprising a first-pass furnace tube 3 and a second-pass furnace tube 4 .

[0067] The inner diameter of the main body of the furnace tube D = 50mm, the length of the main body of the furnace tube L = 13m, such as figure 2 As shown, 8 sets of heat conducting members are evenly arranged on the two ends of the U-shaped tube along the axial direction of the furnace tube, and the extension length of the 8 sets of heat conducting members along the axial direction of the main body of the furnace tube is H=4m.

[0068] The first heat conduction element 1 is a circular ring formed around the cross-section of the inner wall of the main body of the furnace tube, and the diameter d of the inner ring of the first heat conduction element 1 is 12.5mm. A set of heat conduction members includes 15 first heat conduction elements 1 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com