Alumina forming bimetallic tube for refinery process furnaces and method of making and using

A bimetallic tube, alumina technology, used in the petroleum industry, manufacturing tools, metal processing equipment, etc., can solve problems such as poor mechanical integrity and thermal stability, low reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1: Crack-free alumina-forming bimetallic tube made of 9Cr (T9) low chromium steel

[0078] A short length of 9Cr(T9) furnace tube measuring 5.00"OD x 4.25"ID x 12.0"L was prepared and the inner surface of the tube was machined for the PPW method. Alumina forming PPW powder was prepared by argon atomization" M". The powder is sieved to a certain size for easy flow during the PPW process. The chemical composition of the powder "M" in % by weight is the balance Ni:22.93Cr:6.68Al:33.76Fe:0.36Si A bimetallic tube was fabricated by applying powder "M" to the inner surface of a 9Cr furnace tube by the PPW method.

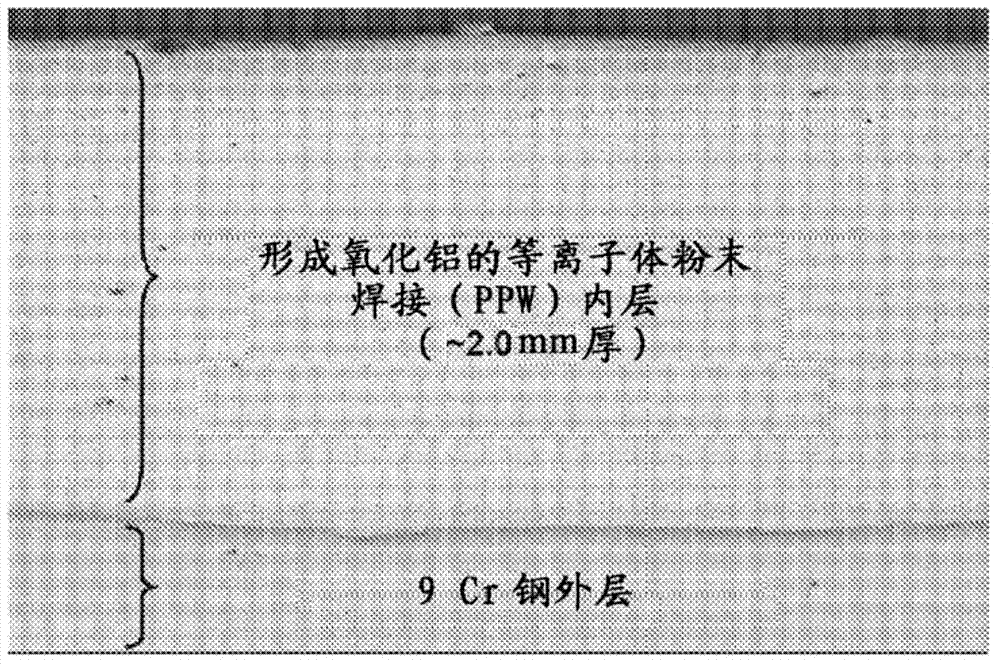

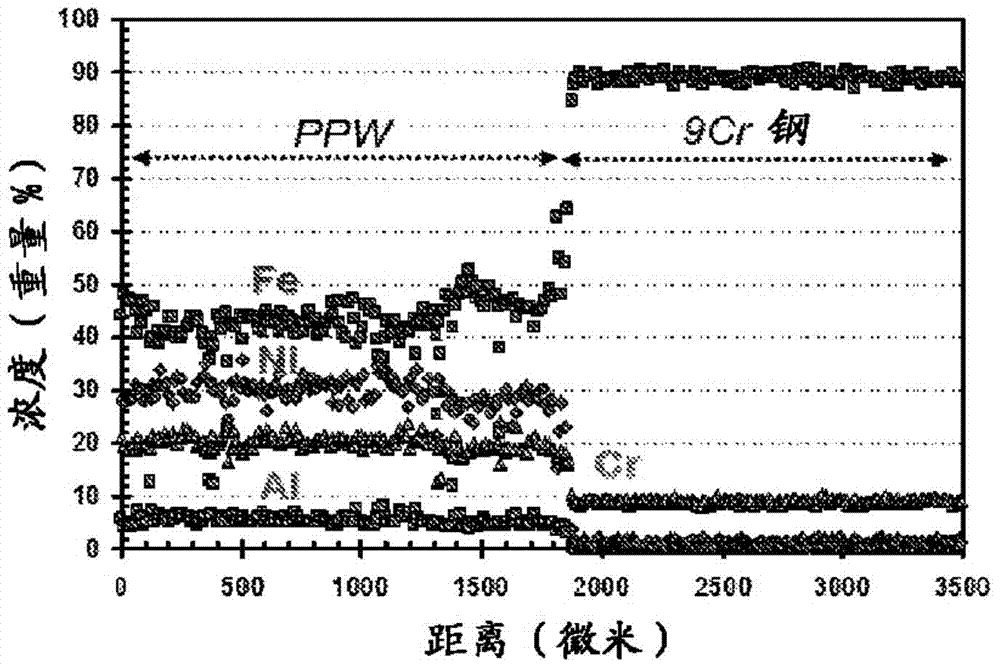

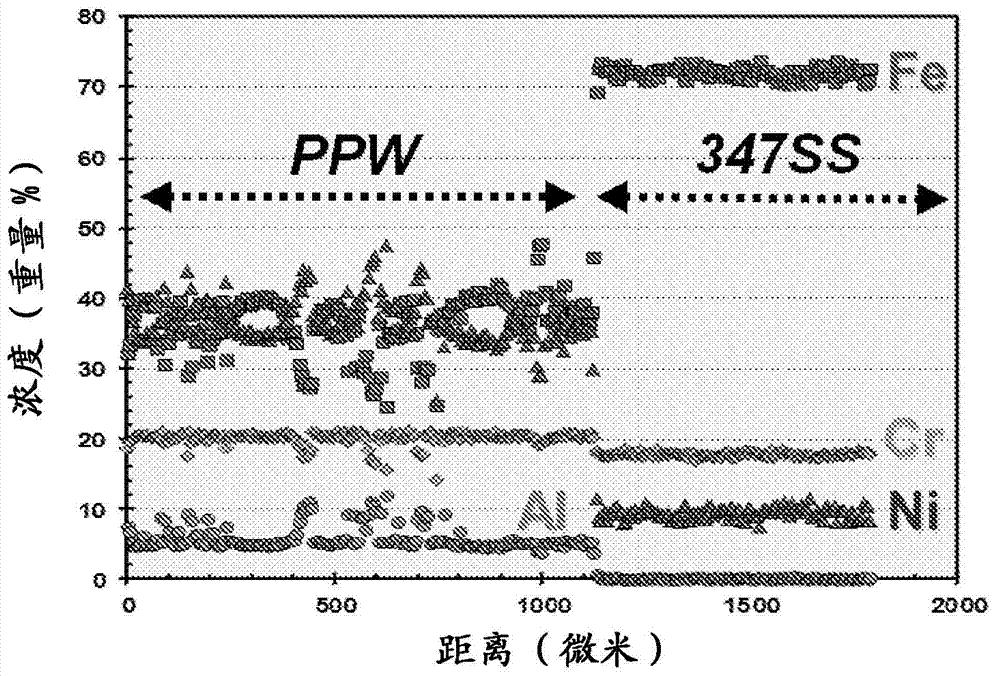

[0079] The resulting bimetallic tube consisted of: i) a 9.5 mm thick outer tube layer of T9 low chromium steel; ii) a 2.0 mm thick inner tube layer formed of aluminum oxide forming alloy lumps; and iii) an inner tube layer on the surface of the inner tube layer A 50 nm thick native alumina film was formed. A cross-sectional view of a bimetallic tube reve...

Embodiment 2

[0081] Example 2: Crack-free alumina-forming bimetallic tube made of 9Cr (T9) low chromium steel

[0082] A short length of 9Cr(T9) furnace tube measuring 5.00"OD x 4.25"ID x 12.0"L was prepared and the inner surface of the tube was machined for the PPW method. Alumina forming PPW powder was prepared by argon atomization" O". The powder is sieved to a certain size for easy flow during the PPW process. The chemical composition of the powder "O" in % by weight is Ni:24.20Cr:6.25Al:32.20Fe:0.14Si with the balance A bimetallic tube was fabricated by applying powder "O" to the inner surface of a 9Cr furnace tube by the PPW method.

[0083] The resulting bimetallic tube consisted of: i) a 9.5 mm thick outer tube layer of T9 low chromium steel; ii) a 2.0 mm thick inner tube layer formed of aluminum oxide forming alloy lumps; and iii) an inner tube layer on the surface of the inner tube layer A 50 nm thick native alumina film was formed. A cross-sectional view of a bimetallic tube...

Embodiment 3

[0085] Example 3 (comparative example): Cracked alumina-forming double-layer steel made of 9Cr (T9) low chromium steel Metal tube

[0086] A short length of 9Cr(T9) furnace tube measuring 5.00"OD x 4.25"ID x 12.0"L was prepared and the inner surface of the tube was machined for the PPW method. Alumina forming PPW powder was prepared by argon atomization" N". The powder is sieved to a certain size for easy flow during the PPW process. The chemical composition of the powder "N" in % by weight is the balance Ni:19.82Cr:7.36Al:39.30Fe:0.25Si A bimetallic tube was fabricated by applying powder "N" to the inner surface of a 9Cr furnace tube via the PPW method.

[0087] The resulting bimetallic tube consisted of: i) a 9.5 mm thick outer tube layer of T9 low chromium steel; ii) a 2.0 mm thick inner tube layer formed of aluminum oxide forming alloy lumps; and iii) an inner tube layer on the surface of the inner tube layer A 50 nm thick native alumina film was formed. A cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com