A kind of powder catalyst for synthesizing ultrafine particle diamond

An ultra-fine particle and diamond technology, which is applied in the field of powder catalyst for synthesizing ultra-fine particle diamond and its preparation field, can solve the problems of difficult synthesis of ultra-fine particle diamond, low nucleation amount, low conversion rate, etc., and achieves the promotion of mass nucleation. , to expand the synthesis range, the effect of easy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

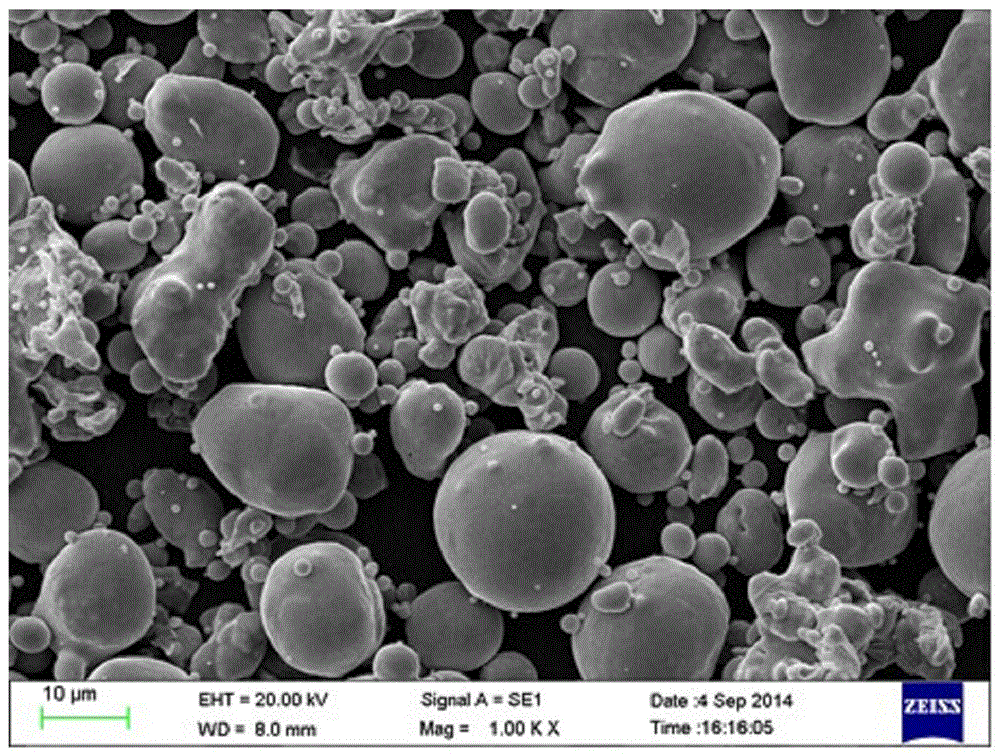

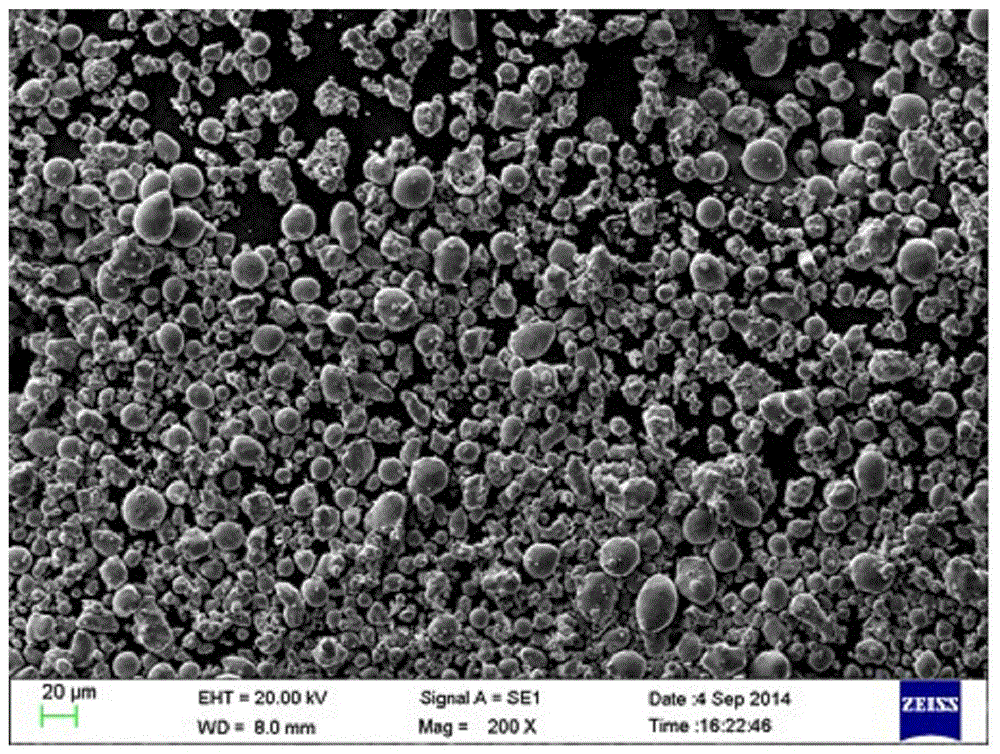

Image

Examples

Embodiment 1

[0032] The powder catalyst for synthesizing ultrafine particle diamond of the present invention is represented by weight percent, and is made of alloy composition Fe 25%, Co 5%, Ce 2%, Mn 5%, SiC 1%, Mo 1% and the balance is Ni.

Embodiment 2

[0034] The powder catalyst for synthesizing ultrafine diamond of the present invention is represented by weight percent, and is made of alloy composition Fe 23%, Co 4%, Ce 1.5%, Mn 3.5%, SiC 0.5%, Mo 0.7% and the balance being Ni.

Embodiment 3

[0036] The powder catalyst for synthesizing ultrafine particle diamond of the present invention is represented by weight percent, and is made of alloy composition Fe 20%, Co 3%, Ce 0.5%, Mn 3%, SiC 1%, Mo 1% and the balance is Ni.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com