Ultra-high pressure brazed connection method for connecting wolfram-diamond/copper-low activation steel

An ultra-high pressure, low activation steel technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of low direct welding strength, and achieve the effect of avoiding direct contact, reducing carburization, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Firstly, a diamond / copper composite material with a volume fraction of diamond particles of 50% was selected as the intermediate layer for welding between the two base materials tungsten and low-activation steel. Calculate the raw material ratio of diamond and copper in the diamond / copper composite material with a volume ratio of 50% according to the designed mold size. Then the prepared diamond and copper powder are wet-mixed with alcohol in a V-shaped mixer and a mortar to make the diamond / copper powder evenly mixed for later use.

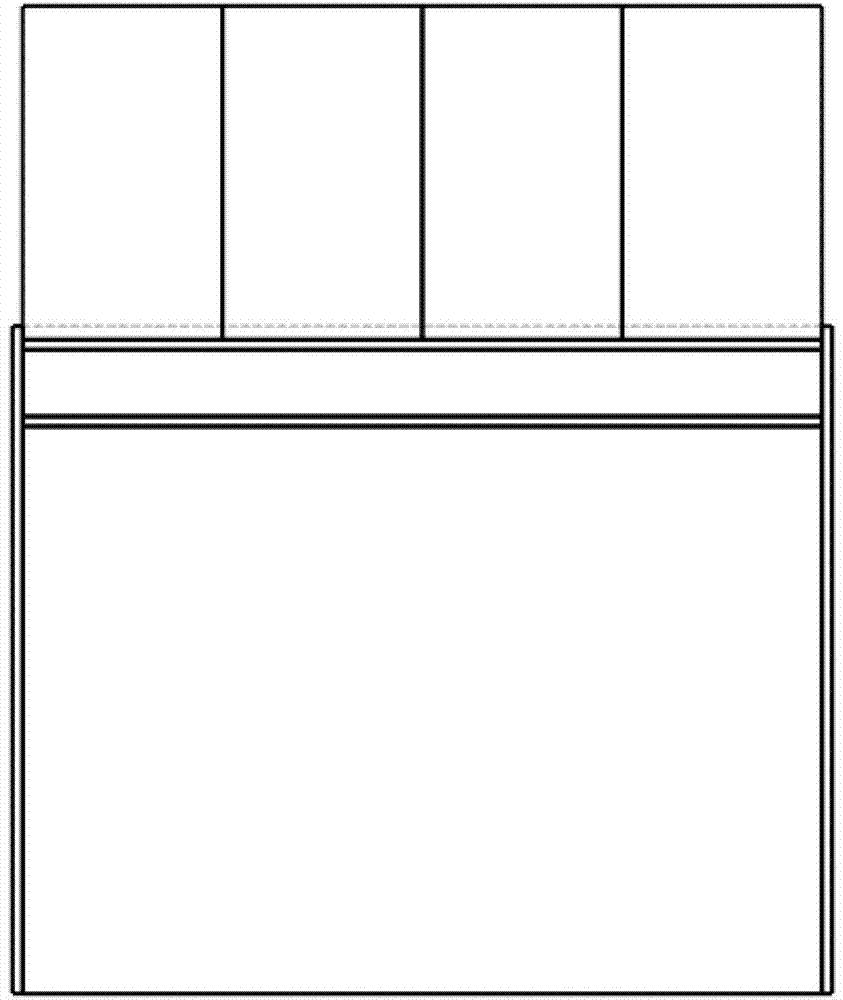

[0026] The tungsten laminations are four tungsten strips with dimensions of 24×10×6mm. Low activation steel size 24×24×17mm. CuCrZr foil size 24×24×0.3mm. Grind, clean and dry the surface of the sample before connecting.

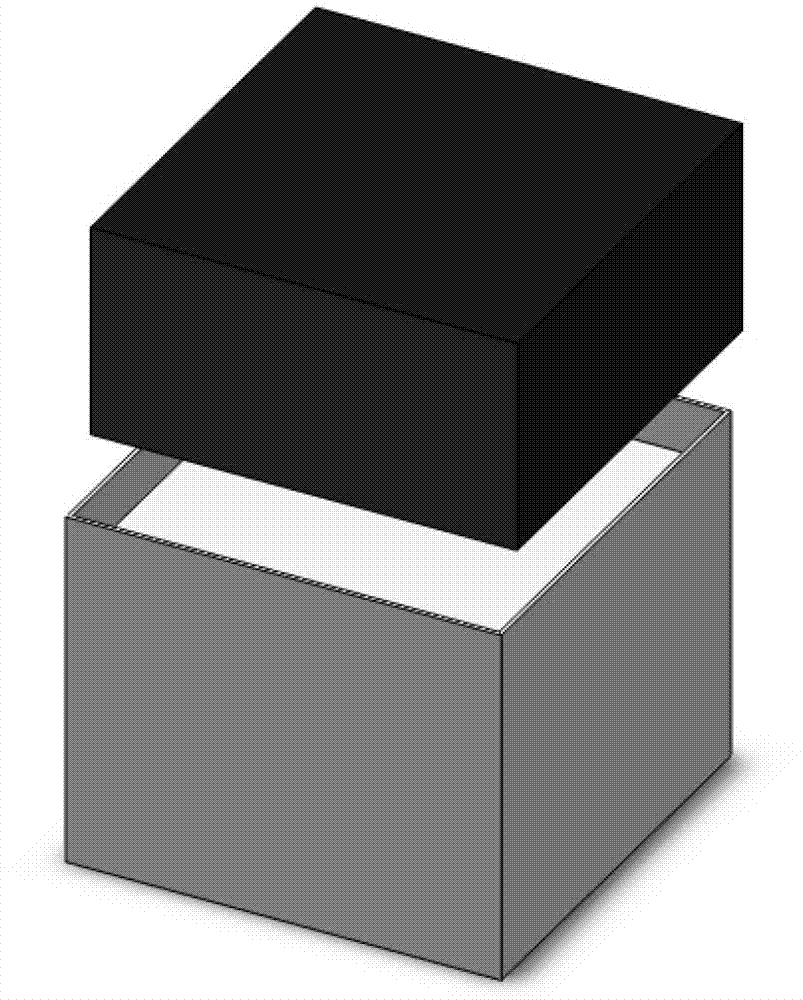

[0027] Put the graphite mold into the graphite mold in the order of low activation steel-CuCrZr foil-diamond / copper mixture-CuCrZr foil-tungsten lamination from top to bottom, and then put the graphite mold into the s...

Embodiment 2

[0030] First, a diamond / copper composite material with a volume fraction of diamond particles of 40% was selected as the intermediate layer for welding between the two base materials tungsten and low-activation steel. Calculate the raw material ratio of diamond and copper in the diamond / copper composite material with a volume ratio of 40% according to the designed mold size. Then the prepared diamond and copper powder are wet-mixed with alcohol in a V-shaped mixer and a mortar to make the diamond / copper raw materials evenly mixed for later use.

[0031] The tungsten laminations are four tungsten strips with dimensions of 24×10×6mm. Low activation steel size 24×24×17mm. CuCrZr foil size 24×24×0.3mm. Grind, clean and dry the surface of the sample before connecting.

[0032] Put the graphite mold into the graphite mold in the order of low activation steel-CuCrZr foil-diamond / copper mixture-CuCrZr foil-tungsten lamination from top to bottom, and then put the graphite mold into ...

Embodiment 3

[0036] First, a diamond / copper composite material with a volume fraction of diamond particles of 45% was selected as the intermediate layer for welding between the two base materials tungsten and low-activation steel. Calculate the raw material ratio of diamond and copper in the diamond / copper composite material with a volume ratio of 45% according to the designed mold size. Then the prepared diamond and copper powder are wet-mixed with alcohol in a V-shaped mixer and a mortar to make the diamond / copper raw materials evenly mixed for later use.

[0037]The tungsten laminations are four tungsten strips with dimensions of 24×10×6mm. Low activation steel size 24×24×17mm. CuCrZr foil size 24×24×0.3mm. Grind, clean and dry the surface of the sample before connecting.

[0038] Put the graphite mold into the graphite mold in the order of low activation steel-OFC foil-diamond / copper mixture-OFC foil-tungsten lamination from top to bottom, and then put the graphite mold into the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com