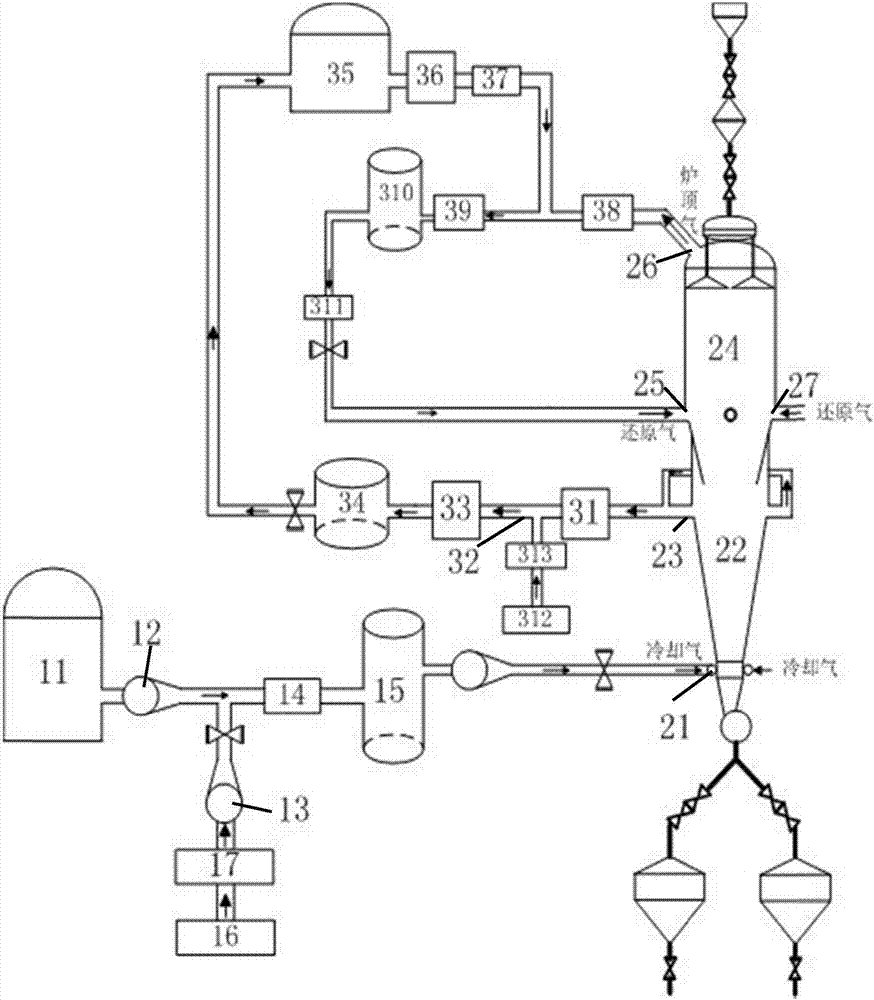

System and method for reducing and cooling metallized pellets

A technology of metallized pellets and cooling gas, applied in the direction of furnace type, furnace, gas emission reduction, etc., can solve problems such as product carbon content fluctuations, achieve the effects of shortened residence time, improved compactness, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

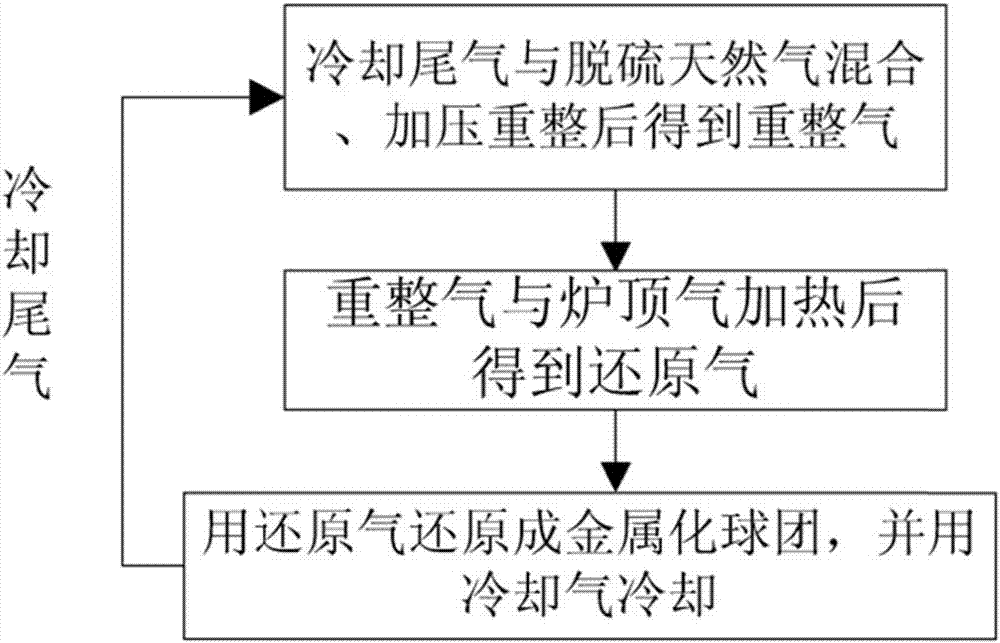

Embodiment 1

[0086] The cooling air temperature is 50°C, the CH in the cooling air 4 The volume fraction is 80%, H 2 O (g) volume fraction is 20%, cooling gas pressure 0.1MPa, cooling gas enters the flow rate 500Nm of the cooling section 22 of air-based shaft furnace 3 / t DRI (DRI, direct reduced iron). Compared with the existing Midrex process, since the catalytic reforming of methane is an endothermic reaction, the residence time of the metallized pellets in the cooling section 22 is shortened by 1 / 4, and the amount of cooling gas is reduced from 1000Nm in the traditional Midrex process. 3 / t reduced to 500Nm 3 / t. Adding an appropriate amount of water vapor into the cooling air suppresses the carburization reaction and iron carburization reaction of the cooling section 22 in the shaft furnace, and can stably control the carbon content of the metallized pellets below 1%. The main component of the tail gas discharged from the cooling section 22 of the shaft furnace is CH 4 , with a s...

Embodiment 2

[0088] The cooling air temperature is 70°C, the CH in the cooling air 4 The volume fraction is 95%, H 2 O (g) volume fraction is 5%, cooling gas pressure 0.2MPa, cooling gas enters the flow rate 700Nm of the cooling section 22 of air-based shaft furnace 3 / tDRI. Compared with the existing Midrex process, since the catalytic reforming of methane is an endothermic reaction, the residence time of the metallized pellets in the cooling section 22 is shortened by 1 / 5, and the amount of cooling gas is reduced from 1000Nm in the traditional Midrex process. 3 / t reduced to 700Nm 3 / t. Adding an appropriate amount of water vapor into the cooling air suppresses the carburization reaction and iron carburization reaction of the cooling section 22 in the shaft furnace, and can stably control the carbon content of the metallized pellets below 1%. The main component of the tail gas discharged from the cooling section 22 of the shaft furnace is CH 4 , with a small amount of H 2 O, CO and...

Embodiment 3

[0090] The cooling air temperature is 60°C, the CH in the cooling air 4 The volume fraction is 85%, H 2 O (g) volume fraction is 15%, cooling gas pressure 0.15MPa, cooling gas enters the flow rate 600Nm of the cooling section 22 of air-based shaft furnace 3 / tDRI. Compared with the existing Midrex process, since the catalytic reforming of methane is an endothermic reaction, the residence time of the metallized pellets in the cooling section 22 is shortened by 1 / 4, and the amount of cooling gas is reduced from 1000Nm in the traditional Midrex process. 3 / t reduced to 600Nm 3 / t. Adding an appropriate amount of water vapor into the cooling air suppresses the carburization reaction and iron carburization reaction of the cooling section 22 in the shaft furnace, and can stably control the carbon content of the metallized pellets below 1%. The main component of the tail gas discharged from the cooling section 22 of the shaft furnace is CH 4 , with a small amount of H 2 O, CO a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com