Thermal protection type coke oven waste heat recovery power generation system based on power source voltage adjustment circuit

A waste heat power generation and coke oven technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as inability to utilize waste heat, reduce manual adjustment errors, increase heat exchange intensity, and achieve convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

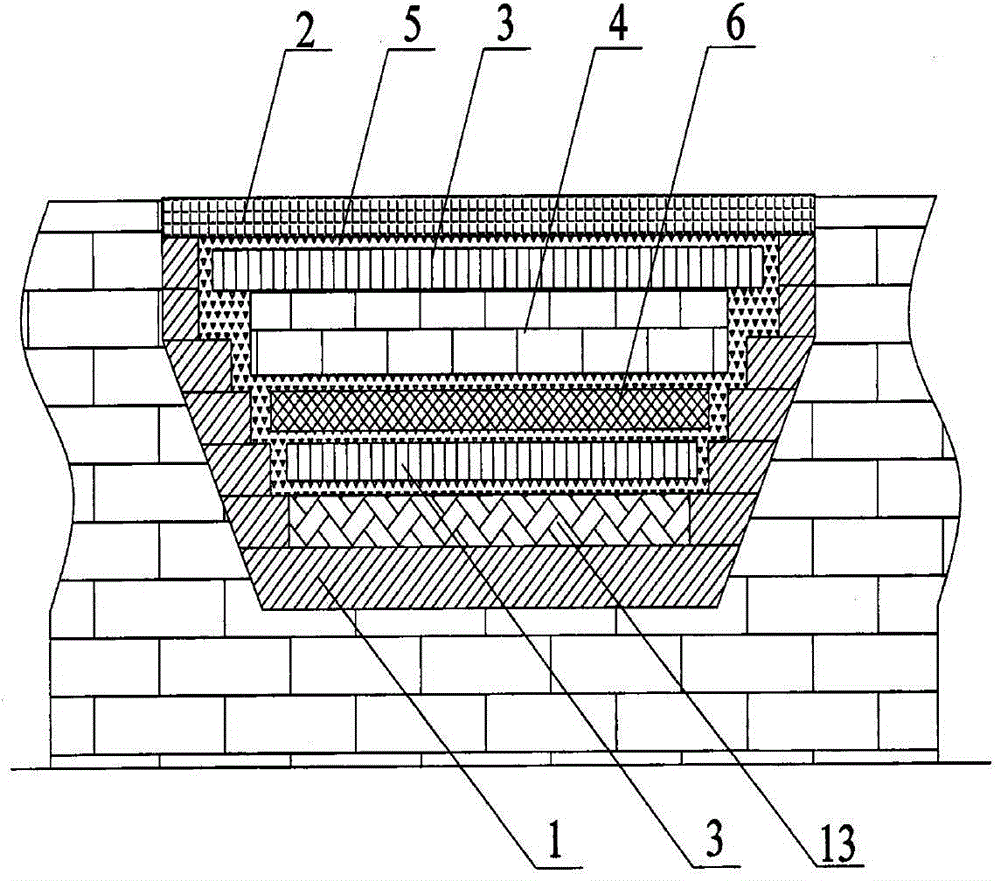

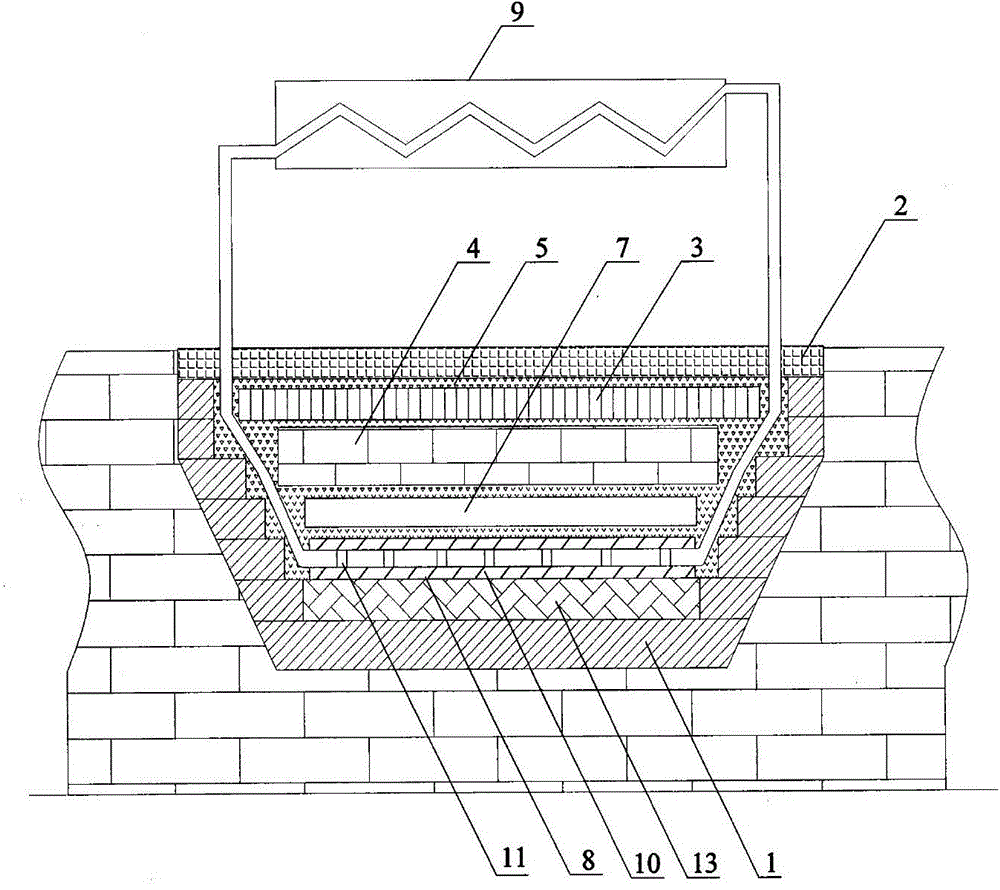

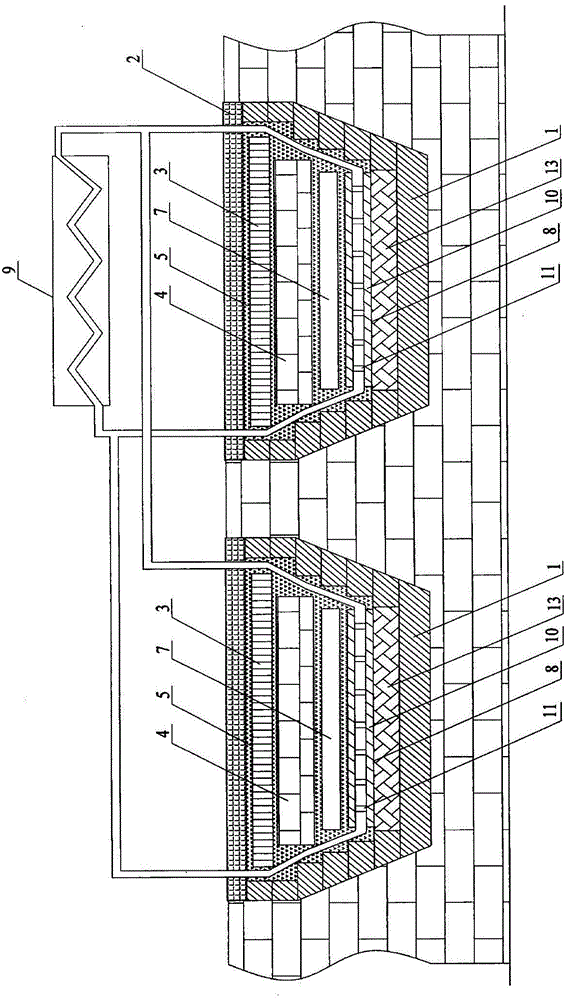

[0033] Such as Figure 1~4 As shown, the coke oven top pit 1 of the present invention is formed by stacking bricks or cement, etc., and the cross section of its internal cavity is in the shape of an inverted trapezoid, that is, the width of the bottom of the coke oven top pit 1 is smaller than that of the top. width, and the bottom of the coke oven top pit 1 is the base 13 of the coke oven top pit 1, and a special heat exchanger system and a non-porous steel plate 7 are also arranged inside the coke oven top pit 1.

[0034] In order to ensure that the present invention can effectively carry out heat preservation and eliminate defects such as smoke and fire, a perforated steel plate 3, a heat insulating plate layer 4, a Perforated steel plate 3 and furnace top clinker brick 2. Because when laying, not only there are gaps between the perforated steel plate 3 and the heat insulating plate layer 4, between the heat insulating plate layer 4 and the perforated steel plate 3, betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com